Anti-slip hole sealing method for gas extraction drill hole of underground bottom drainage roadway

A technology of gas drainage and bottom drainage roadway, which is applied in the direction of gas discharge, mining equipment, earthwork drilling, etc., and can solve the problems of affecting the efficiency and effect of gas extraction, the inability to insert the hole sealer smoothly, and increasing the workload of workers, etc. Achieve the effect of simple structure, improved sealing effect, and improved pressure bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

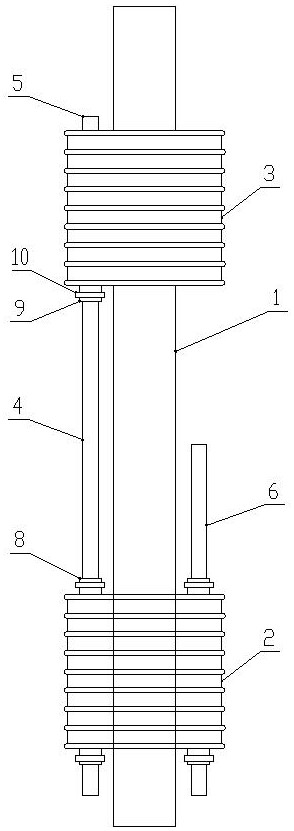

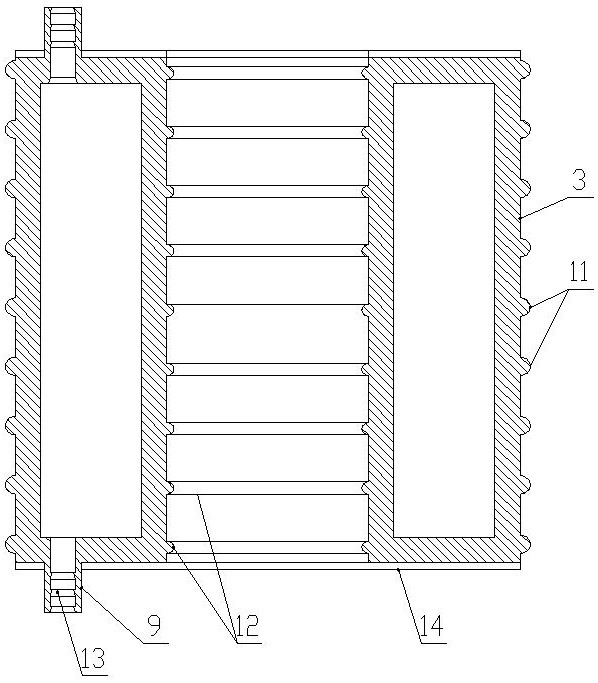

[0043] Embodiment one: if Figure 1-4 As shown, the gas drainage drilling method of the present invention comprises the following steps:

[0044] (1) In the bottom pumping roadway, use drilling rigs to drill holes in the upper coal seam at different angles;

[0045] (2) Install the upper colloidal fetal sac 3 and the lower colloidal fetal sac 2 on the extraction pipe 1, penetrate the grouting pipe on the upper colloidal fetal sac 3 and the lower colloidal fetal sac 2, and assemble it into an anti-slip fetal sac sealer ;

[0046] (3) Insert the anti-slip tire bag sealer into the drilled hole;

[0047] (4) Connect the front port of the grouting pipe of the anti-slip tire bag sealer to the grouting pump, and inject grout into the anti-slip tire bag sealer. The tire bladder 2 expands and squeezes the hole wall of the drilled hole, and the anti-slip tire bladder sealer is suspended in the drilled hole under the friction between the colloid tire bladder and the drilled hole wall;...

Embodiment 2

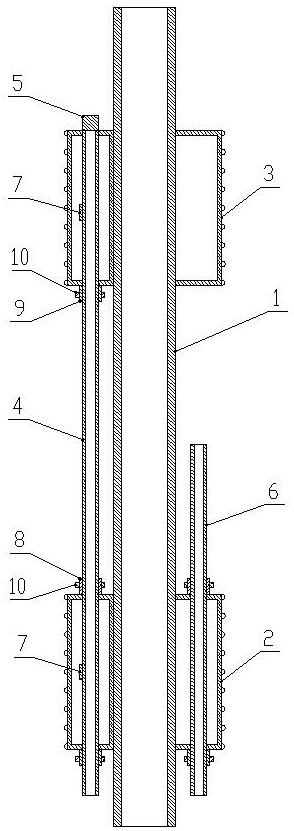

[0058] Embodiment two: if Figure 5-Figure 8 As shown, the gas drainage drilling method of the present invention comprises the following steps:

[0059] (1) In the bottom pumping roadway, use drilling rigs to drill holes in the upper coal seam at different angles;

[0060] (2) Install the upper colloidal fetal sac 3 and the lower colloidal fetal sac 2 on the extraction pipe 1, penetrate the grouting pipe on the upper colloidal fetal sac 3 and the lower colloidal fetal sac 2, and assemble it into an anti-slip fetal sac sealer ;

[0061] (3) Insert the anti-slip tire bag sealer into the drilled hole;

[0062] (4) Connect the front port of the grouting pipe of the anti-slip tire bag sealer to the grouting pump, and inject grout into the anti-slip tire bag sealer. The tire bladder 2 expands and squeezes the hole wall of the drilled hole, and the anti-slip tire bladder sealer is suspended in the drilled hole under the friction between the colloid tire bladder and the drilled hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com