Construction method for prestressed reinforcement of frame beam

A construction method and prestressing technology, applied in building maintenance, construction, building construction, etc., can solve the problem of limited reinforcement strength of frame beams, and achieve the effects of improving integrity, increasing shear strength, and enhancing compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

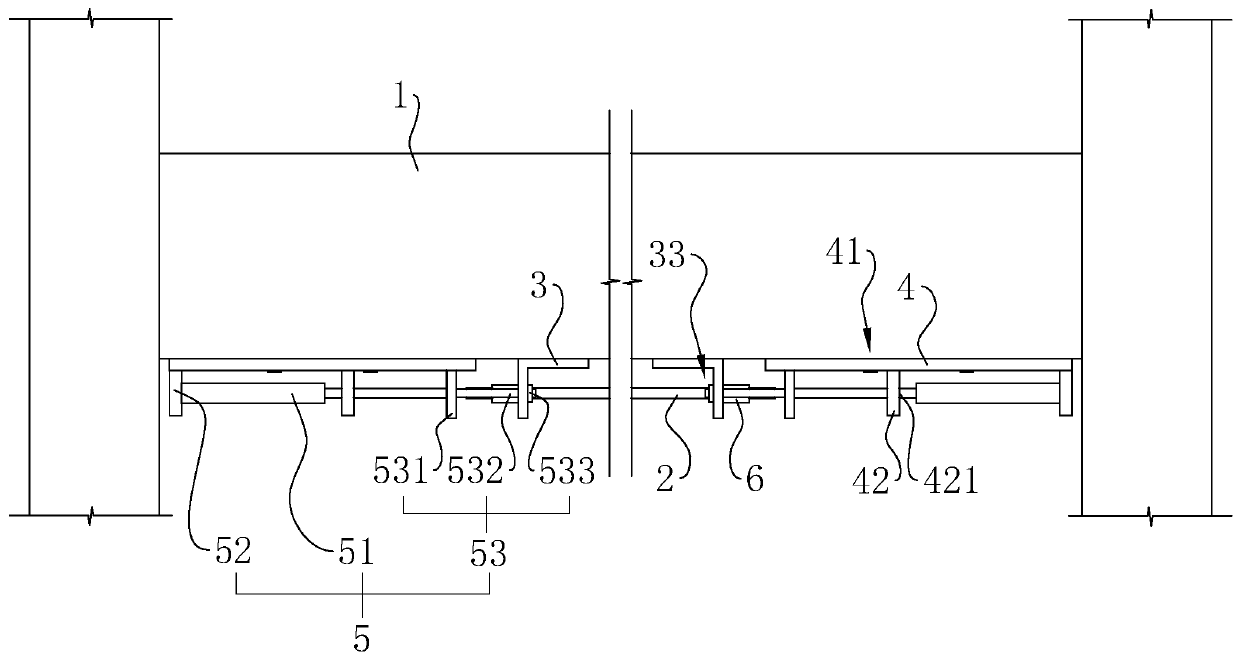

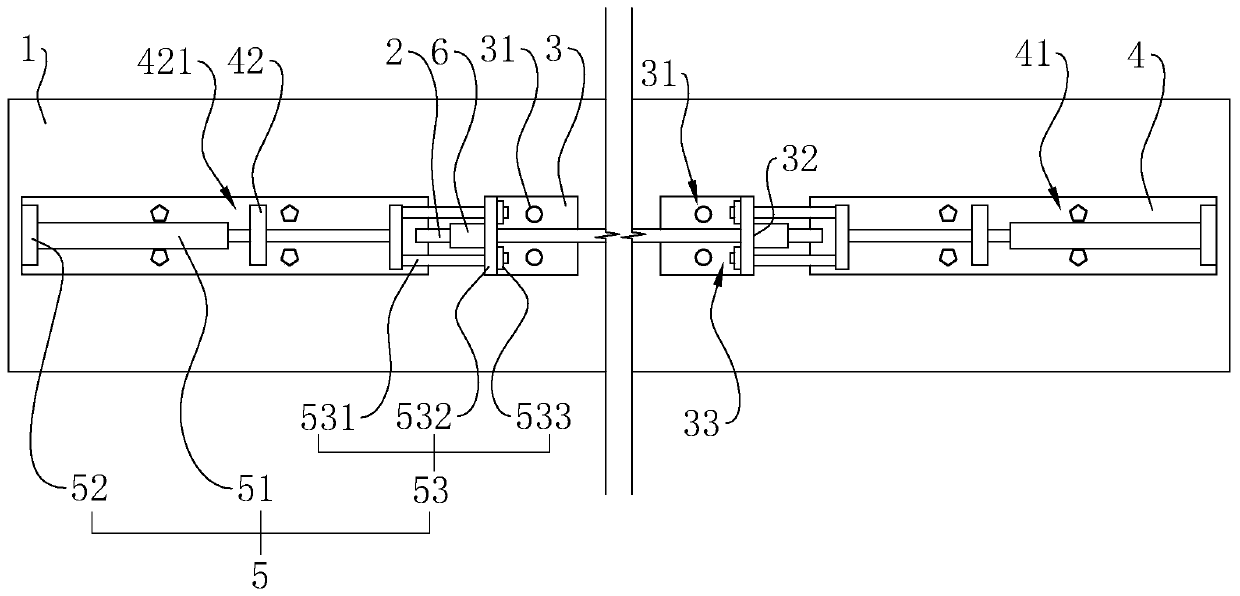

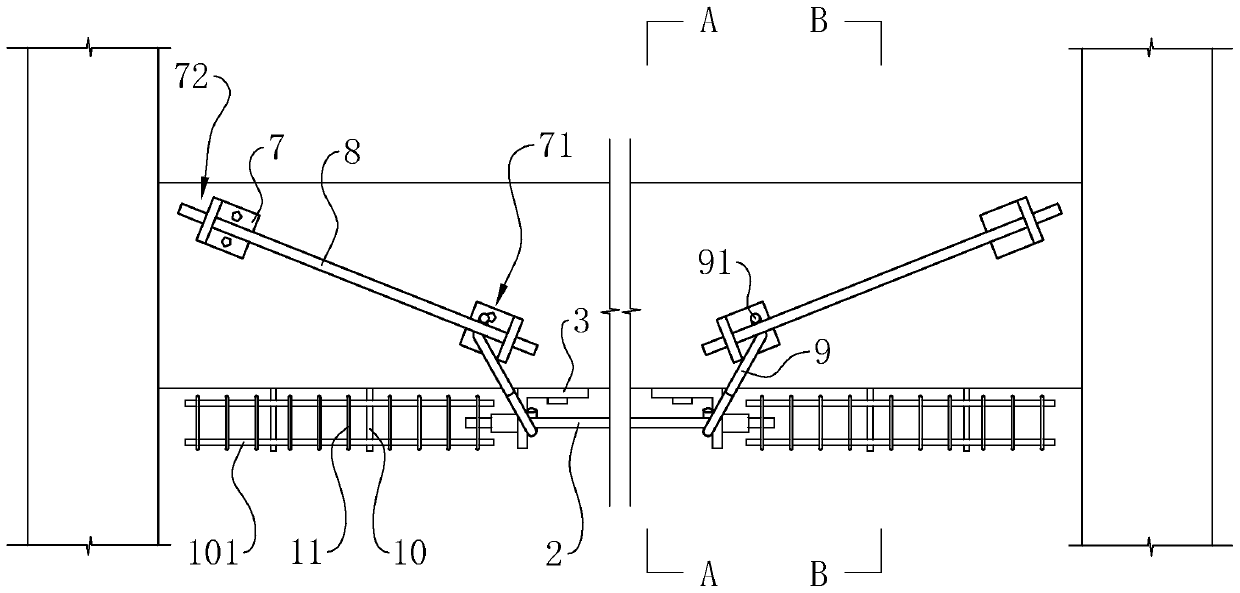

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0052] refer to figure 1 , is a construction method for prestressed reinforcement of a frame beam disclosed by the present invention, comprising the steps of:

[0053] S1, surface treatment;

[0054] The original surface layer of the frame beam 1 is peeled off to expose the concrete on the frame beam 1 . The concrete surface of the frame beam 1 is cleaned with a high-pressure air gun, so that there is no dust residue on the concrete surface of the frame beam 1 . Unload the floor adjacent to the frame beam 1, and support the scaffolding at the bottom of the floor adjacent to the frame beam 1 to buffer the floor's own weight and reduce the force transmitted from the floor to the frame beam 1.

[0055] According to the design requirements, carry out lofting on the surface of the frame beam 1 to determine the installation position of each device.

[0056] S2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com