Cold-rolled steel pipe capable of being conveniently preliminarily positioned and assembled and spraying equipment

A spraying equipment and initial positioning technology, applied in the field of cold-rolled steel pipe production, to achieve the effects of improving service life, reducing joint fractures, and enhancing bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following is attached Figure 1-13 The application is described in further detail.

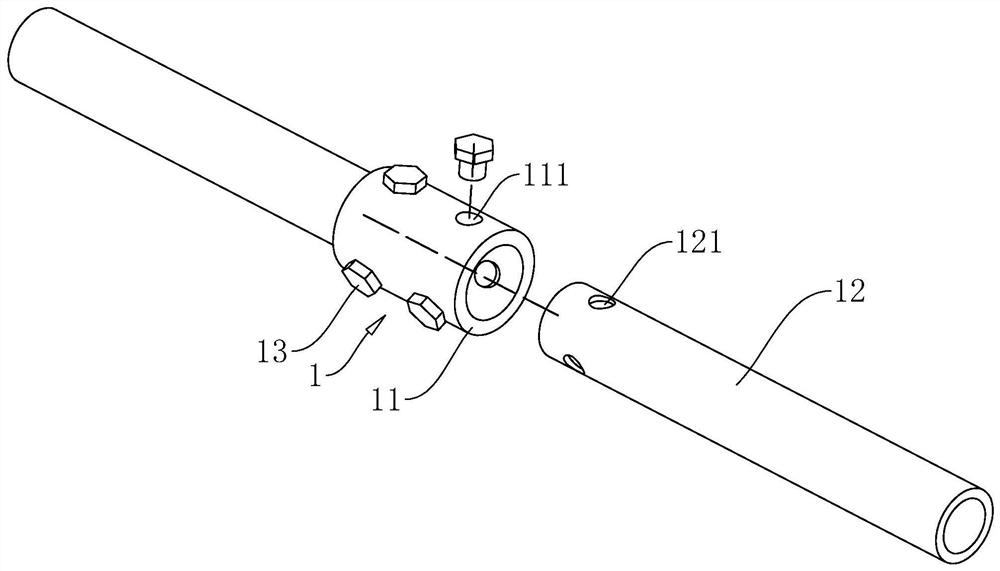

[0053] refer to figure 1 , the connector 1 in the related art can use the installation sleeve 11 and the installation bolt 13, the installation sleeve 11 is set on the outer periphery of the junction of the two steel pipes 12, and the outer circumference of the installation sleeve 11 is drilled to the outer circumference of the steel pipe 12. The first threaded hole 111, the overlapping part of the two steel pipes 12 and the installation sleeve 11 needs to correspond to the first threaded hole 111 to drill the second threaded hole 121, and then install the bolt 13 from the first threaded hole 111 to the second threaded hole 121, so that the installation sleeve 11 and the steel pipe 12 are connected and fixed by the installation bolt 13, after the two steel pipes 12 are connected with the installation sleeve 11 by the installation bolt 13, the two steel pipes 12 are connected and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com