Subway tunnel shield synchronous grouting intelligent monitoring system

An intelligent monitoring system and synchronous grouting technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as construction risks, shield machines not being able to stop for a long time, and affecting construction, to achieve reliable data support and effective The effect of convenience in emergency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

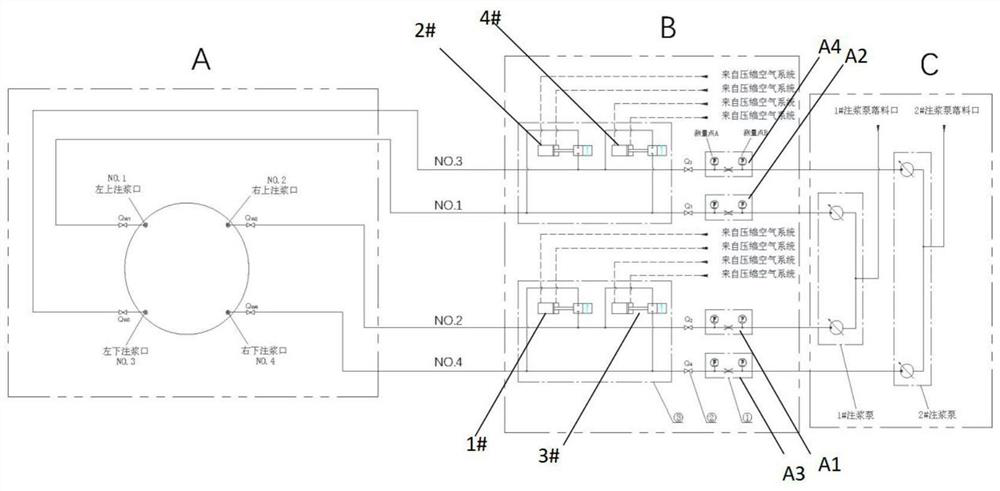

[0071] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Wherein, this device takes a shield machine with two pumps as an example to illustrate the principle of the technical solution of the present invention.

[0072] Such as figure 1 , image 3 and Figure 12 As shown, the main design components are:

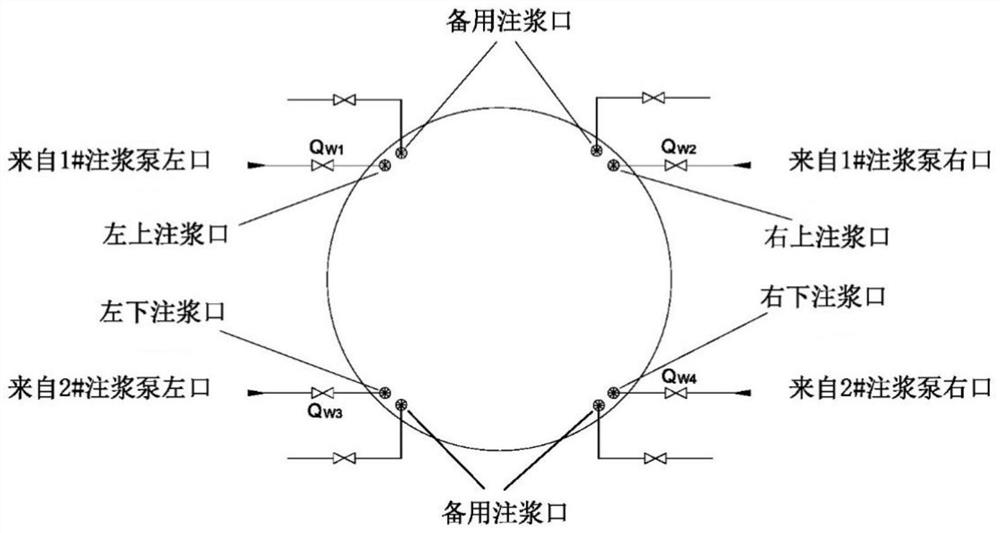

[0073] Area A is the schematic diagram of the shield tail of the shield machine, which includes the upper left grouting port, the upper right grouting port, the lower left grouting port, and the lower right grouting port. Each grouting port is equipped with a manual ball valve.

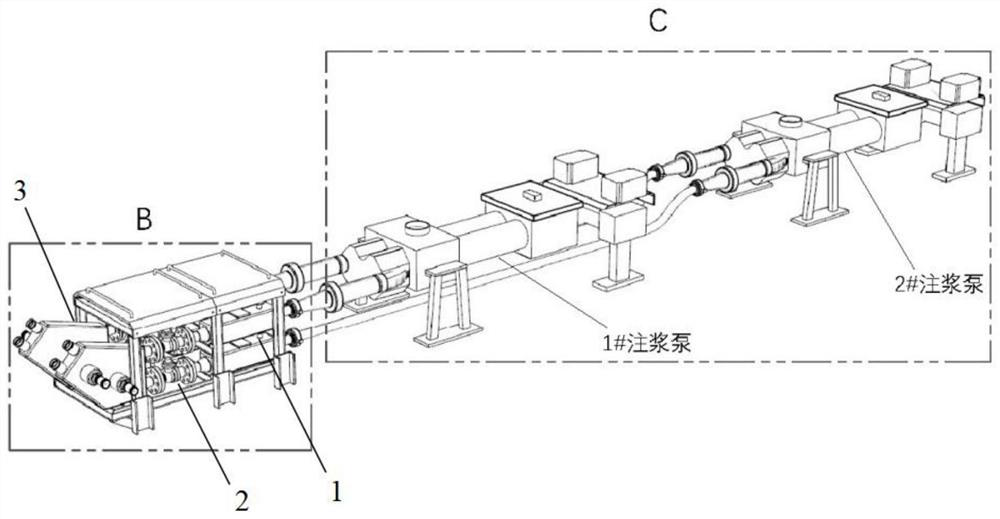

[0074] Such as Figure 4 As shown, area B is the emergency switching device 3, ball valve group 2, and branch flowmeter group 1 designed in this application.

[0075] Area C is the two grouting pumps on the 1# trolley of the shield machine, which are respectively numbered 1# grouting pump and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com