Efficient dedusting and drying device for rice production

A drying device, rice technology, applied in the direction of drying, drying machine, cleaning device, etc., can solve the problems of low efficiency and manpower consumption, and achieve the effect of ensuring uniformity, improving efficiency and quality, and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

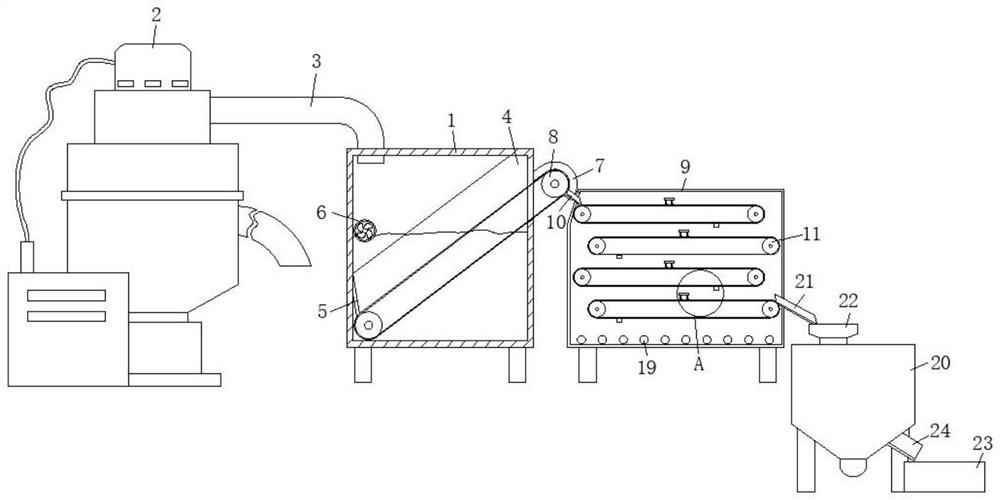

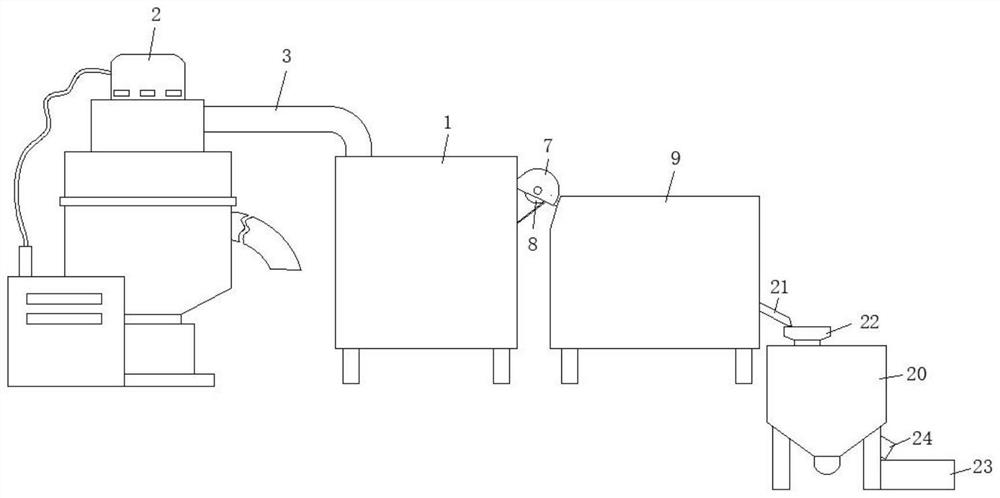

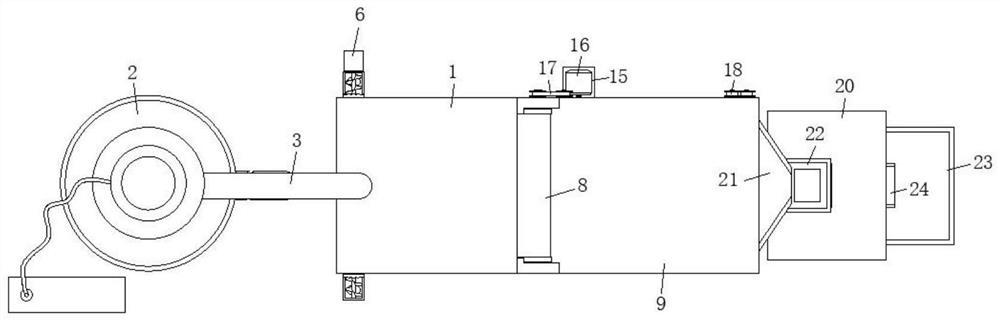

[0032] refer to Figure 1-5 , a high-efficiency dust removal and drying device for rice production, comprising a washing box 1, a negative pressure suction machine 2 is installed on one side of the water washing box 1, and the output end of the negative pressure suction machine 2 is connected through the top side of the water washing box 1 There is a feeding pipe 3, a material guide plate 4 is fixed on the front and rear inner walls of the upper end of the washing box 1, two material guide plates 4 are fixedly connected with a baffle plate 5 on the side close to the negative pressure suction machine 2, and the middle part of the washing box 1 is close to the negative pressure suction machine. One side of the material machine 2 is also connected with a debris extraction mechanism 6, and the upper end of the washing box 1 is away from the negative pressure suction machine 2. A stopper 7 is fixed on the side, and the two stoppers 7 are rotated and installed between the bottom side...

Embodiment 2

[0035] like figure 1 and 6As shown, this embodiment is basically the same as Embodiment 1. Preferably, the debris extraction mechanism 6 includes a material extraction pipe 601, which is connected through the middle of the washing tank 1, and the rear end surface of the material extraction tube 601 is fixedly installed with a drive The motor 602, the output end of the drive motor 602 extends into the pumping pipe 601 and is fixed with a feeding pipe 603, the front and rear outer walls of the feeding pipe 603 are fixed with a conveying auger 604, and the bottom surface of the middle part of the pumping pipe 601 is also provided with an arc The groove 605 and the bottom surface of the front and rear sides of the suction pipe 601 are also provided with discharge holes 606 . The conveying auger 604 on the front and rear side outer walls of the feed pipe 603 rotates in opposite directions, and the drive motor 602 is fixed on the water washing tank 1 rear side wall.

[0036] In th...

Embodiment 3

[0038] like figure 1 and 5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the feeding end of the feeding pipe 3 is located on the top surface of the washing tank 1 near the side of the negative pressure suction machine 2 .

[0039] The lower ends of the material guide plate 4 and the baffle plate 5 are all bonded to the upper surface of the conveyor belt 8, and the material guide plate 4 is arranged in an arc shape.

[0040] In the present embodiment, the lower ends of the material guide plate 4 and the baffle plate 5 are all attached to the upper surface of the conveyor belt-8, so as to ensure that the rice can be smoothly output from the washing box 1 by the conveyor belt-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com