Sand cleaning device for water pump blank machining

A blank processing and sand cleaning technology, which is applied to metal processing equipment, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems affecting sand cleaning efficiency, sand cleaning blind spots, and water pump blank offsets, etc., to achieve Prevent the blind area of sand cleaning, thoroughly clean the sand, and improve the effect of sand cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

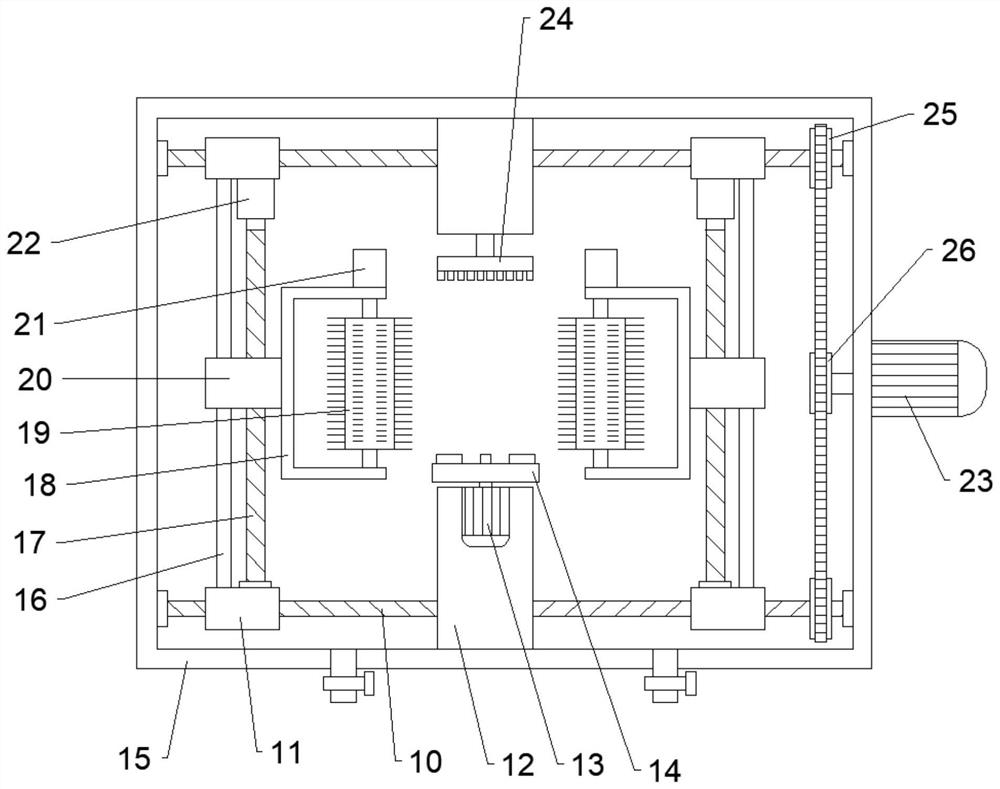

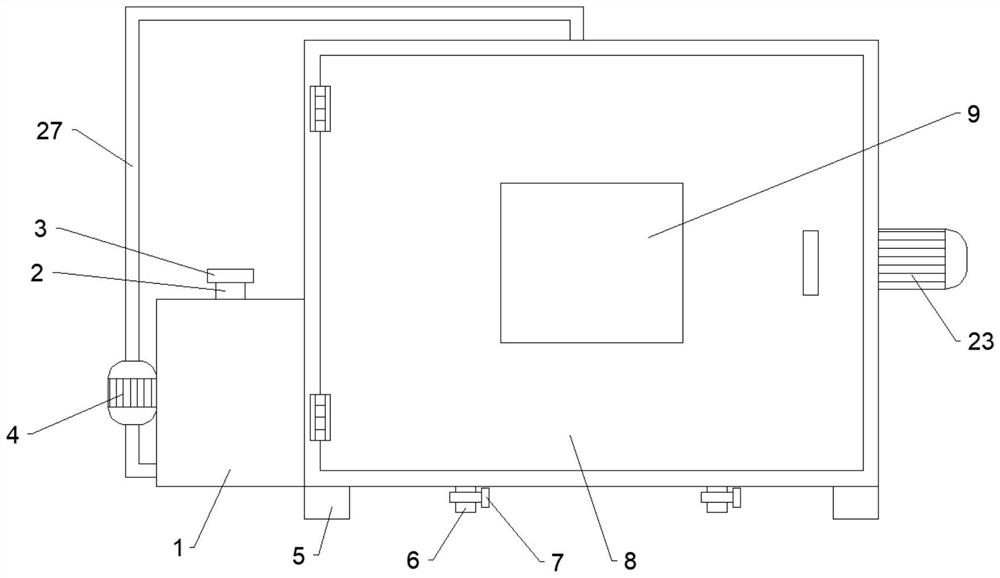

[0024] Example: such as figure 1 with figure 2 As shown, a sand cleaning device for water pump blank processing includes a sand cleaning box 15, a water tank 1 is connected to the outer wall of one side of the sand cleaning box 15, and a fixed water tank 1 is installed in the middle of the inner walls of the upper and lower sides of the sand cleaning box 15. Seat 12, the upper and lower sides of the inner wall of the sand cleaning box 15 are respectively rotated and connected with a two-way screw 10, and the opposite sides of the two-way screw 10 are respectively threaded through and provided with a moving block 11, and two moving blocks 11 are arranged on the same side. A slide bar 16 is connected between the blocks 11, and the slide bar 16 slides through and is provided with a lifting block 20, and U-shaped plates 18 are respectively connected on the opposite inner walls of the two lifting blocks 20, and the U-shaped plates 18 are respectively connected. A roller brush 19 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com