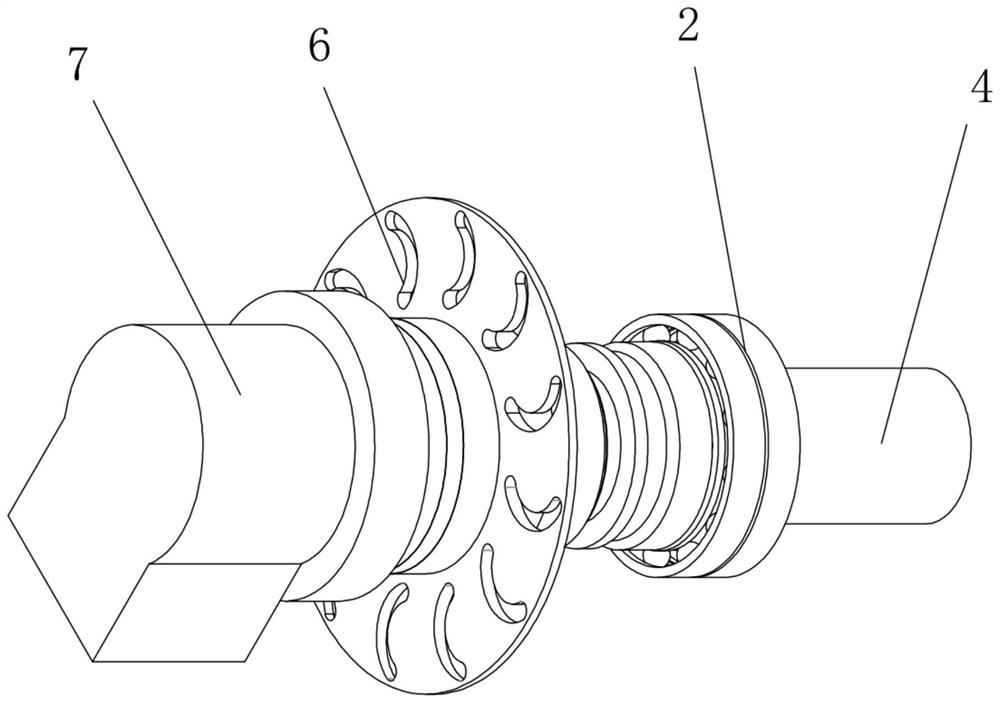

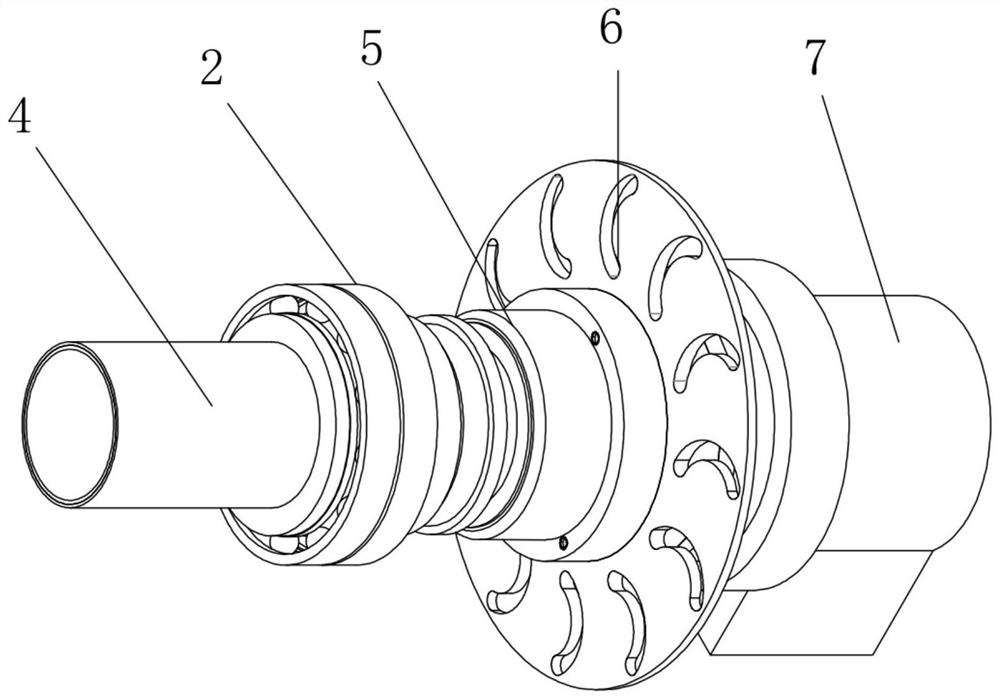

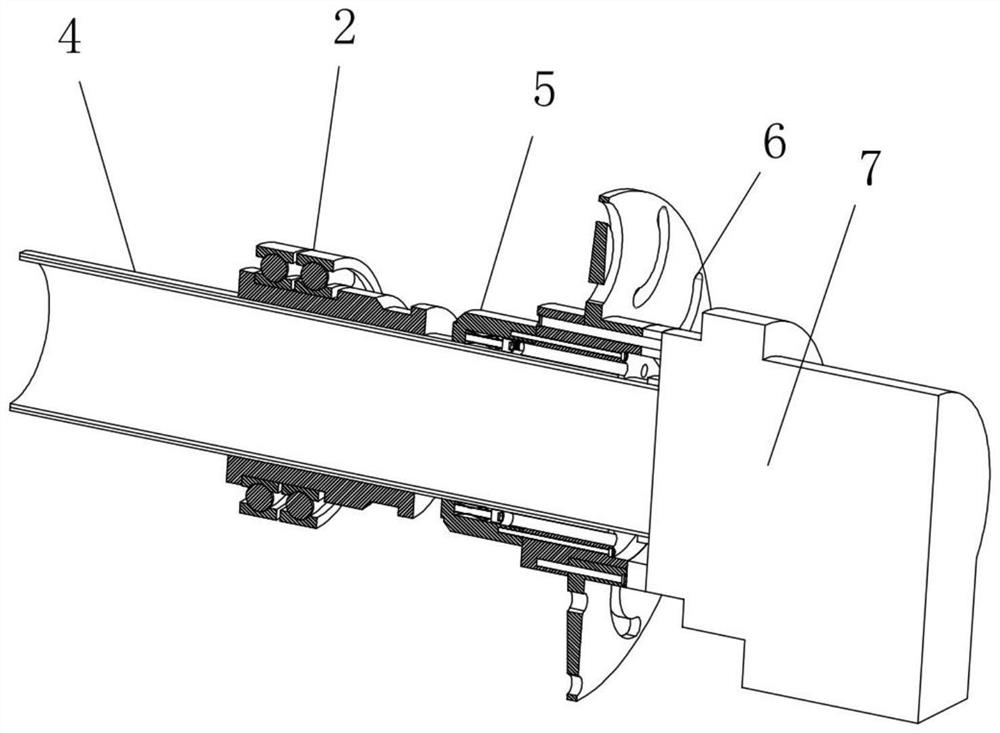

Lathe electric spindle limiting structure

A limit structure, electric spindle technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of bolt damage, failure to ensure the stability of electric spindle and equipment, and inability to adapt to various installation environments , to prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035]In the installation work of the A2-6 interface lathe electric spindle 1, a lathe electric spindle limit structure provided by the present invention is used as the limit structure when installing the electric spindle 1. The A2-6 series electric spindle 1 is considering various designs When required, the shaft is affected by various aspects, and the shaft wall is extremely thin, only 8.5mm thick, so the axial limit step cannot be generated; the tail end must also ensure load bearing, and the traditional radial key positioning method cannot be used to reduce the electric current. The rigidity of the main shaft 1; the threaded hole on the side of the shaft is tightened with a standard screw, and the short thread is not enough for the force bearing surface, and also reduces the rigidity of the electric main shaft 1. Therefore, a new solution is urgently needed to solve the above problems, so the present invention is designed as an electric motor. The new method of installing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com