Co-beam laser cutting device with double cutting heads

A laser cutting, laser cutting head technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of weak adaptability, small functionality, high cost, improve cutting efficiency, improve the scope of use, sliding Scope widening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

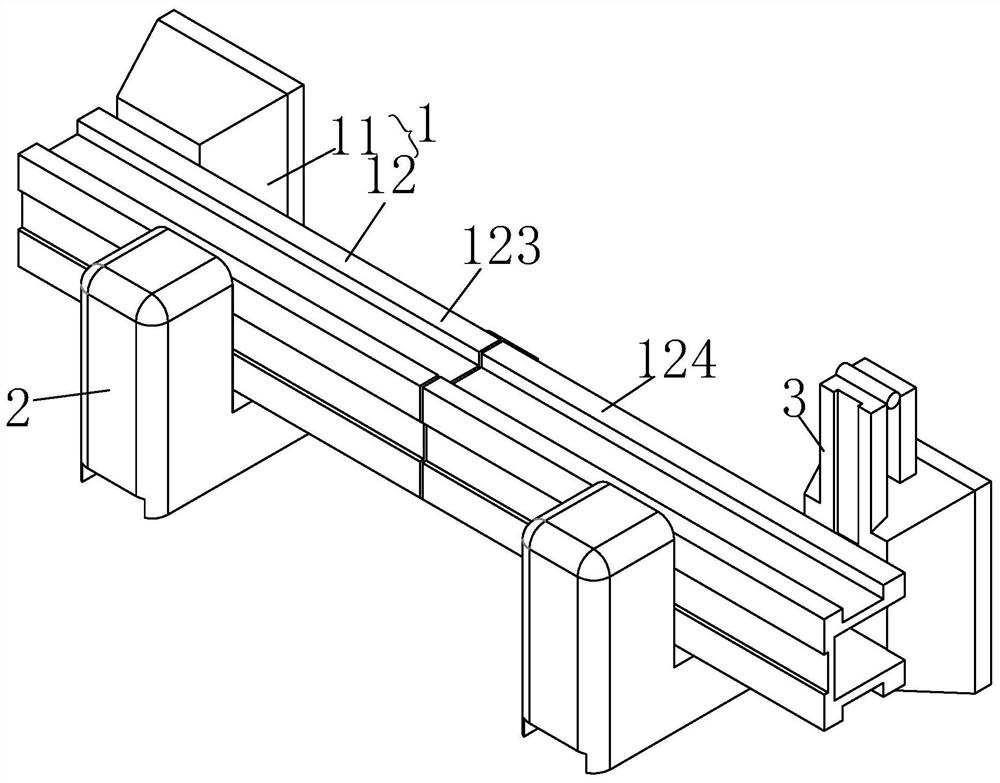

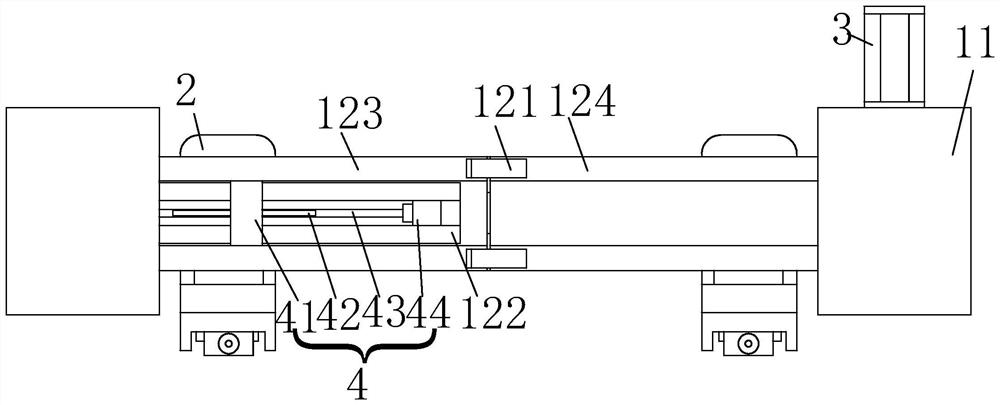

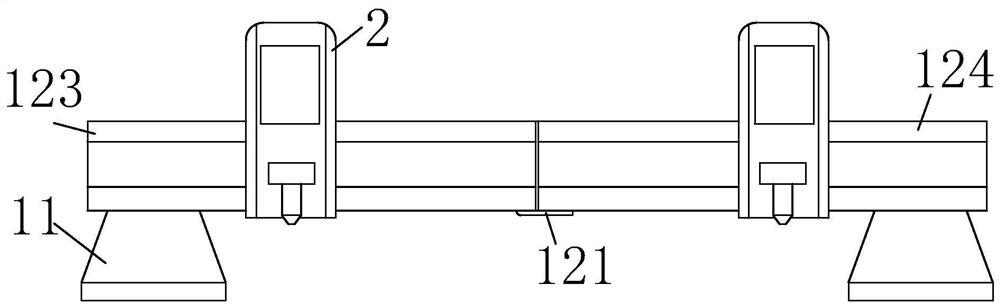

[0027] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] The reference signs and components involved in the accompanying drawings are as follows:

[0029] A laser cutting device with a common beam double cutting head according to the present invention, specifically, by setting two laser cutting heads on the same beam to realize double-line cutting of the plate in the cutting area, the cutting efficiency is improved, and it is aimed at relatively complex plate shapes. Cutting, the original common beam cutting device is transformed into two independent cutting units, so as to realize the shape cutting of the target plate, reduce the number of round trips of the laser cutting head, and improve the cutting efficiency.

[0030] like Figure 1-Figure 7 As shown, a laser cutting device with a common beam double cutting head includes a support assembly 1 on which two laser cutting heads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com