Small part comparison detection clamping device and method

A clamping device and parts technology, which is applied in the field of small parts comparison detection clamping device, can solve problems such as not suitable for rapid replacement of various products, improve detection accuracy and efficiency, have a high degree of automation, and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

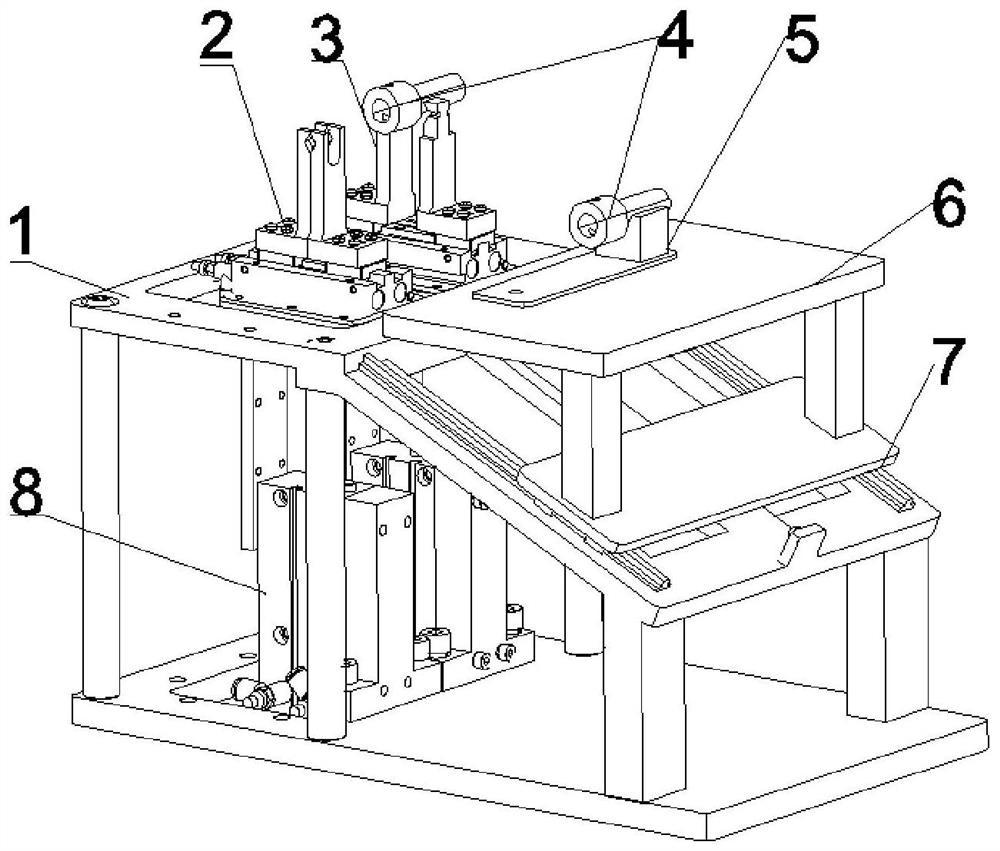

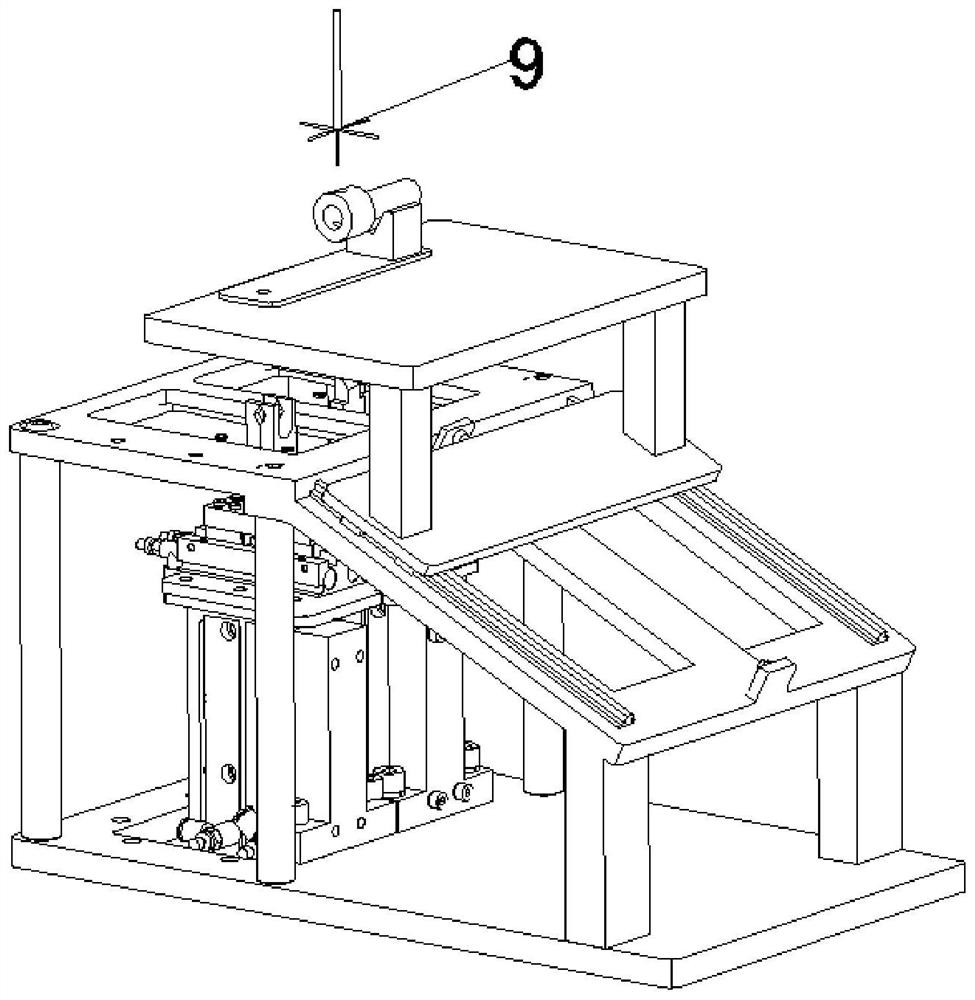

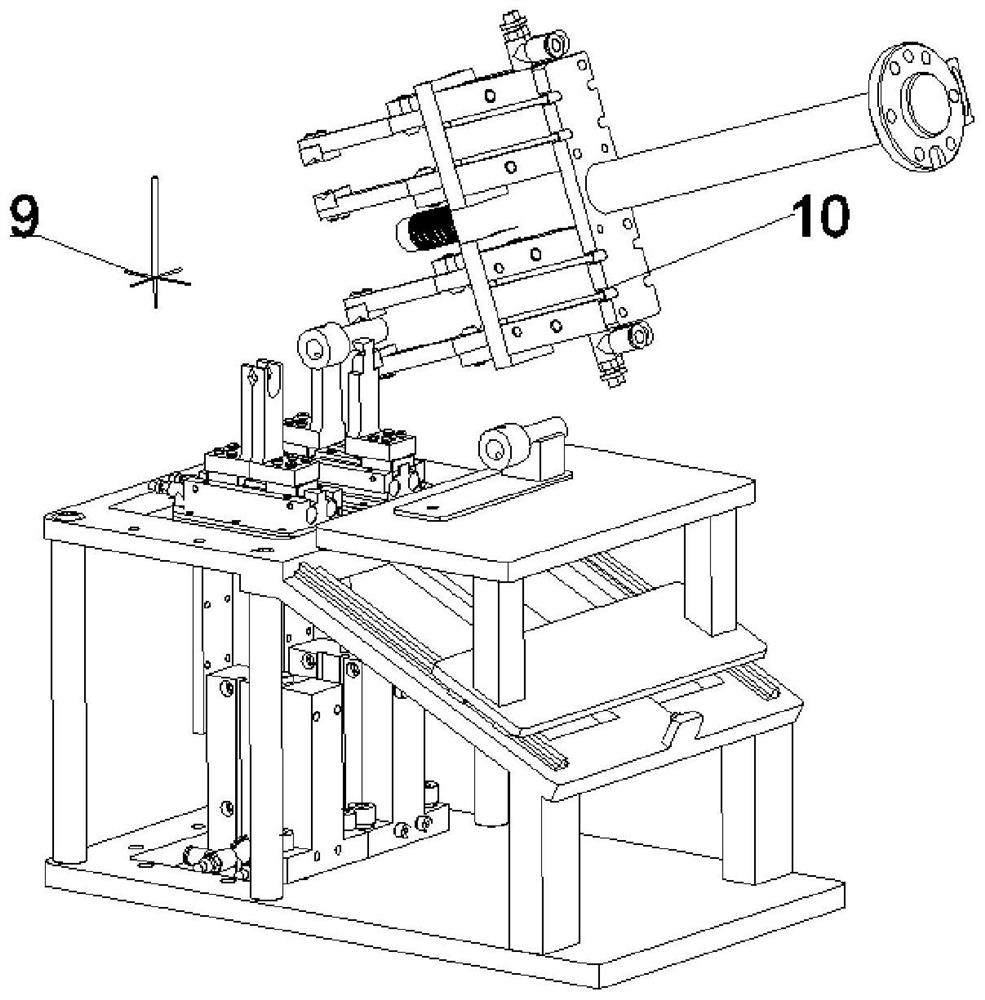

[0039] The present invention proposes a small parts comparison detection clamping device and method. The device of the present invention includes: a clamping device bracket 1, a jaw assembly, a standard part clamping device, an inclined guide rail 7 and a reciprocating cylinder 8.

[0040] Wherein the reciprocating cylinder 8 is two groups of cylinders, the jaw assembly includes the first jaw 2 and the second jaw 3, and the reciprocating cylinder 8 can drive the first jaw 2 and the second jaw 3 to move up and down respectively; when measuring a short workpiece , two jaws lift up one, when measuring long workpieces, both jaws lift up at the same time. The bottoms of the first jaw 2 and the second jaw 3 respectively have step positioning planes. When the jaws rise, the step positioning planes contact and position with the limiting surface in the clamping device bracket 1 to ensure the positioning accuracy each time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com