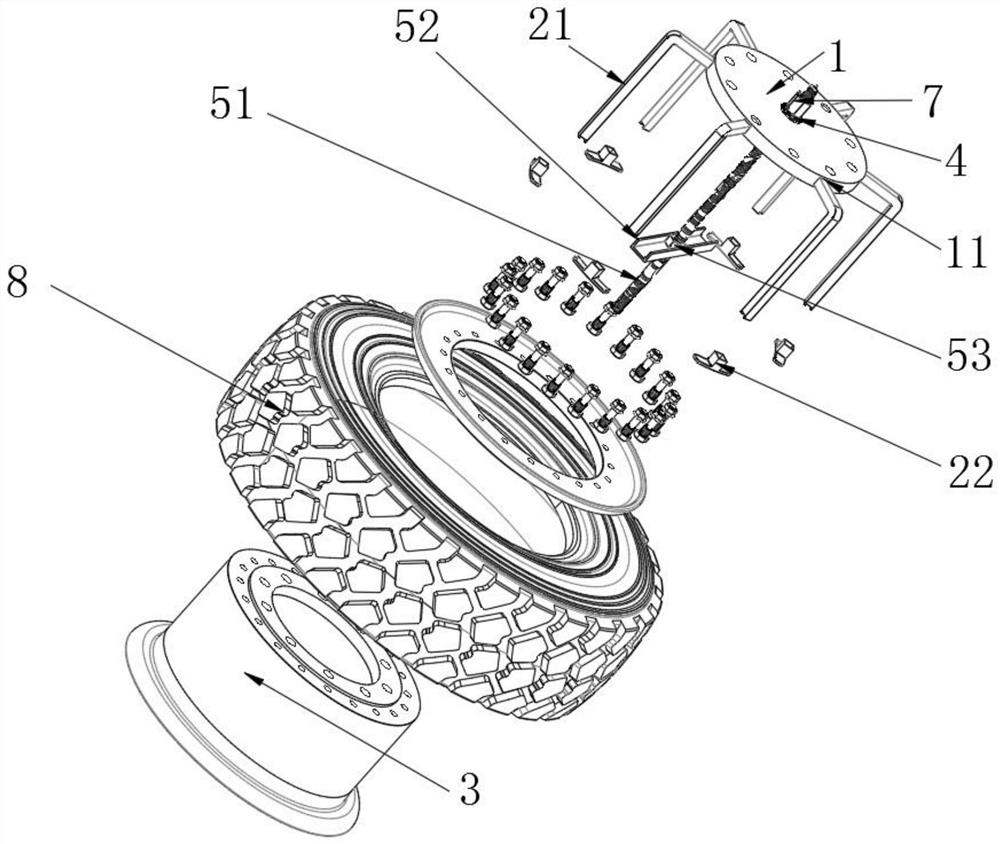

Device for conveniently assembling and disassembling split hub and tire

A split-type, easy-to-install technology, which is applied in tire installation, tire parts, transportation and packaging, etc., can solve the problems of expensive tires, split wheels and tires, difficult tire assembly and disassembly, etc., to reduce Difficulty, easy assembly and disassembly, and the effect of reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

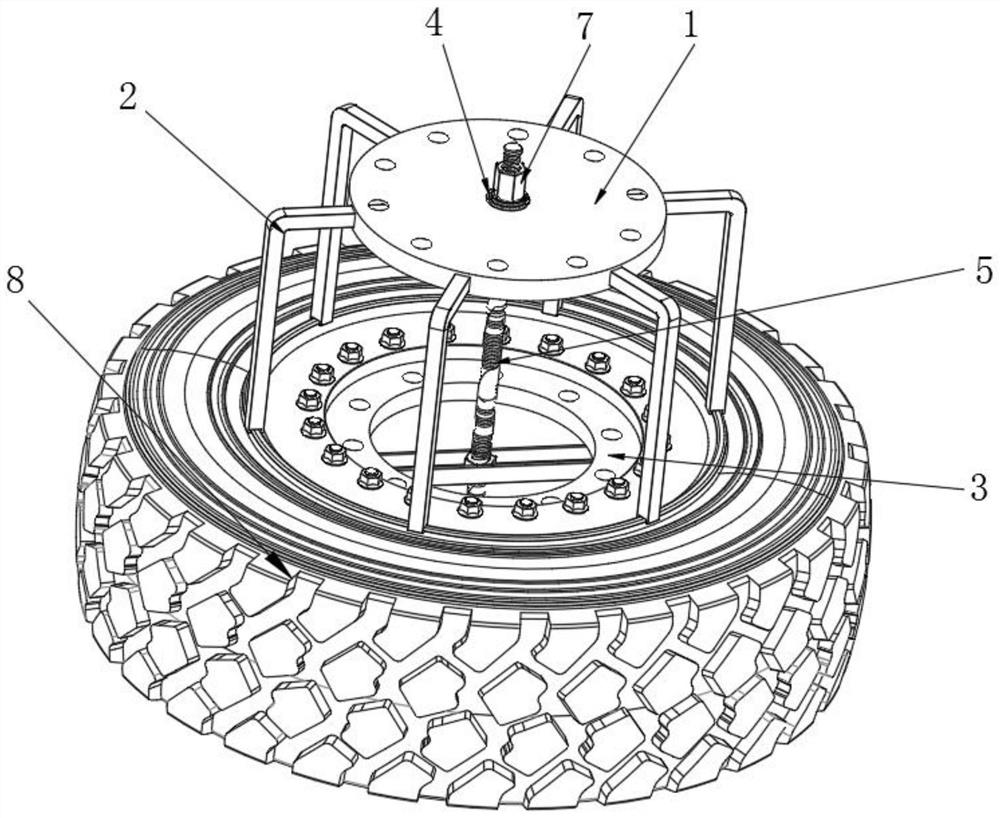

[0027] When the present invention installs tire 8, please refer to figure 2 , clamp the lower bead lip of the tire 8 on the edge of the wheel hub 3, place it horizontally, then pass the base mechanism 5 through the center hole of the wheel hub 3, and the bracket mechanism 2 is stuck on the upper cover plate of the wheel hub 3, so that the L-shaped support feet 21 The groove 23 at the bottom is stuck on the flange on the upper cover plate, and then the nut 7 is rotated with an auxiliary tool to tighten the screw rod 51, so that the multi-point force can be evenly distributed on the surface of the tire 8 through the upper cover plate, so that The tire 8 moves downward under force, and after reaching the end, the screws on the upper cover plate of the wheel hub 3 are installed, and then the device is reset, and the installation is completed.

Embodiment 2

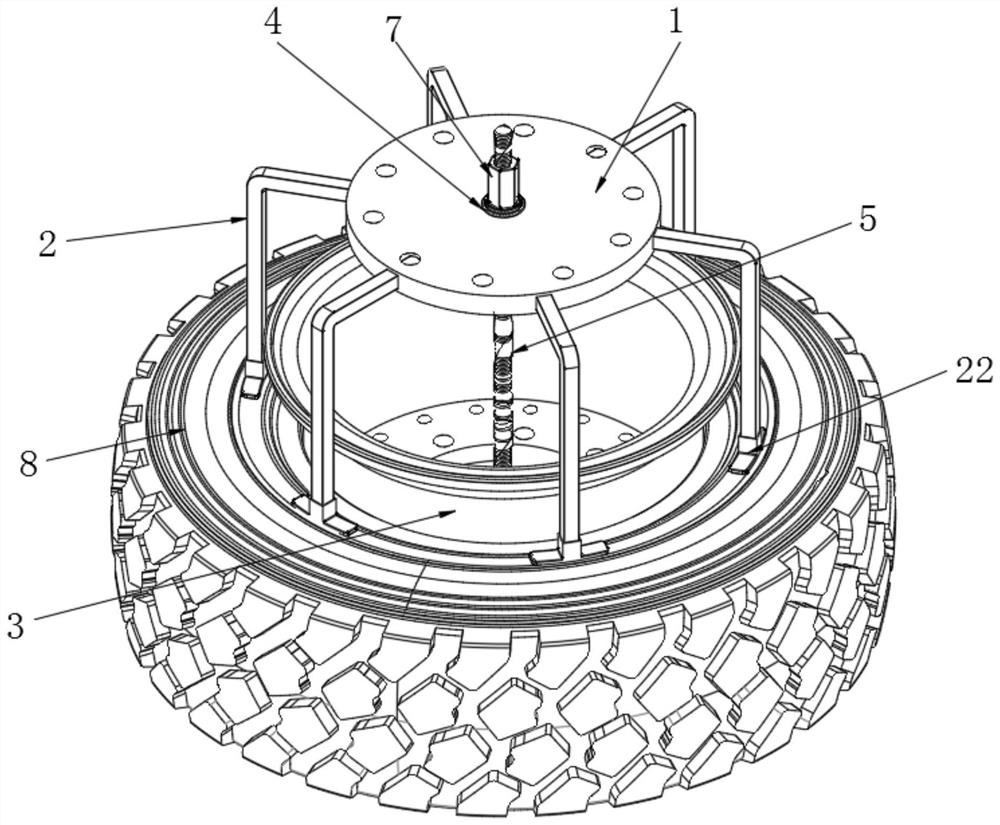

[0029] When the present invention dismounts tire 8, please refer to image 3 , lift the wheel hub 3, so that the tire 8 has enough space to lower it, then put the support pad 22 on the L-shaped support foot 21, press the tire 8 near the edge of the wheel hub 3, turn the nut 7, tighten the screw rod 51, Act on the tire 8 through the principle of action force and reaction force, tighten the base 52, so that the tire 8 is pressed down in a balanced force until it comes out of the hub 3. If this device is not used, it is generally necessary to use an iron when disassembling the tire 8. The hammer and warp are knocked at the place where tire 8 bead and wheel hub are in contact, which is time-consuming and labor-intensive.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap