Silencing structure for improving ventilation efficiency and ventilation stability of ventilation system

A technology of ventilation system and stability, applied in the field of muffler structure, can solve the problems of low ventilation efficiency, long muffler length, difficult to clean, low ventilation efficiency, etc., to achieve the effect of guaranteeing the effect, ensuring ventilation stability, and improving the exhaust efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0046] When the muffler body 42 needs to be cleaned after the fan has been muffled for a long time:

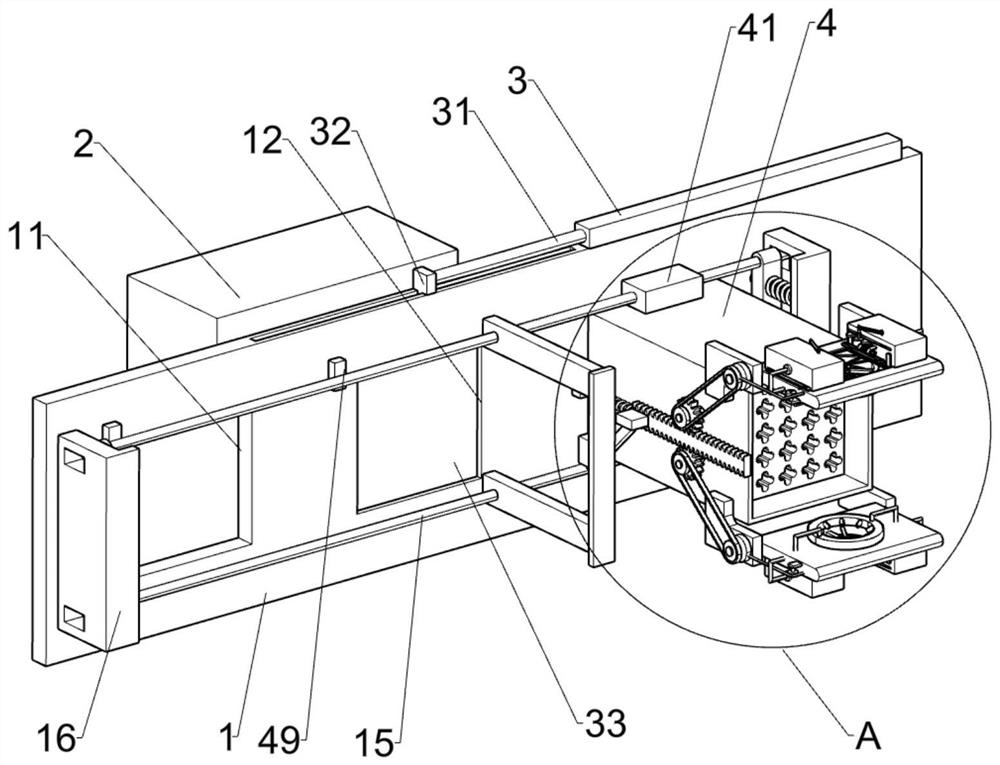

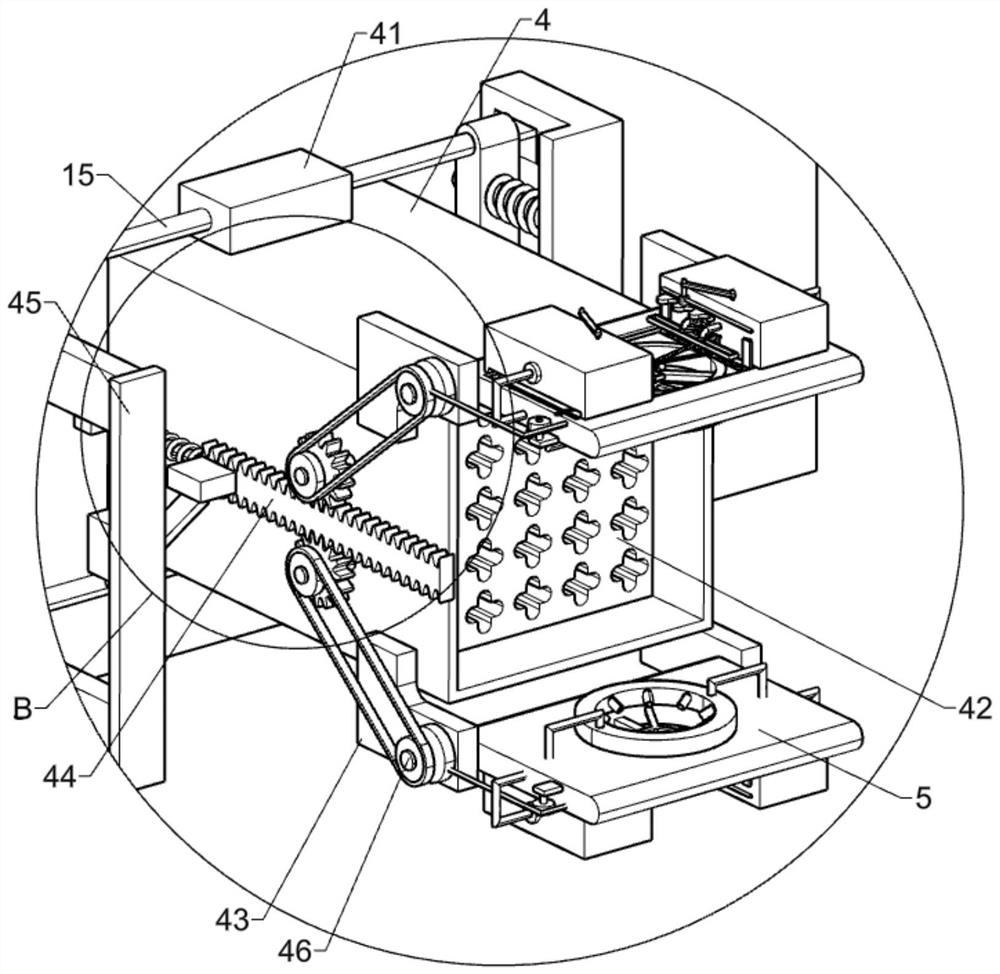

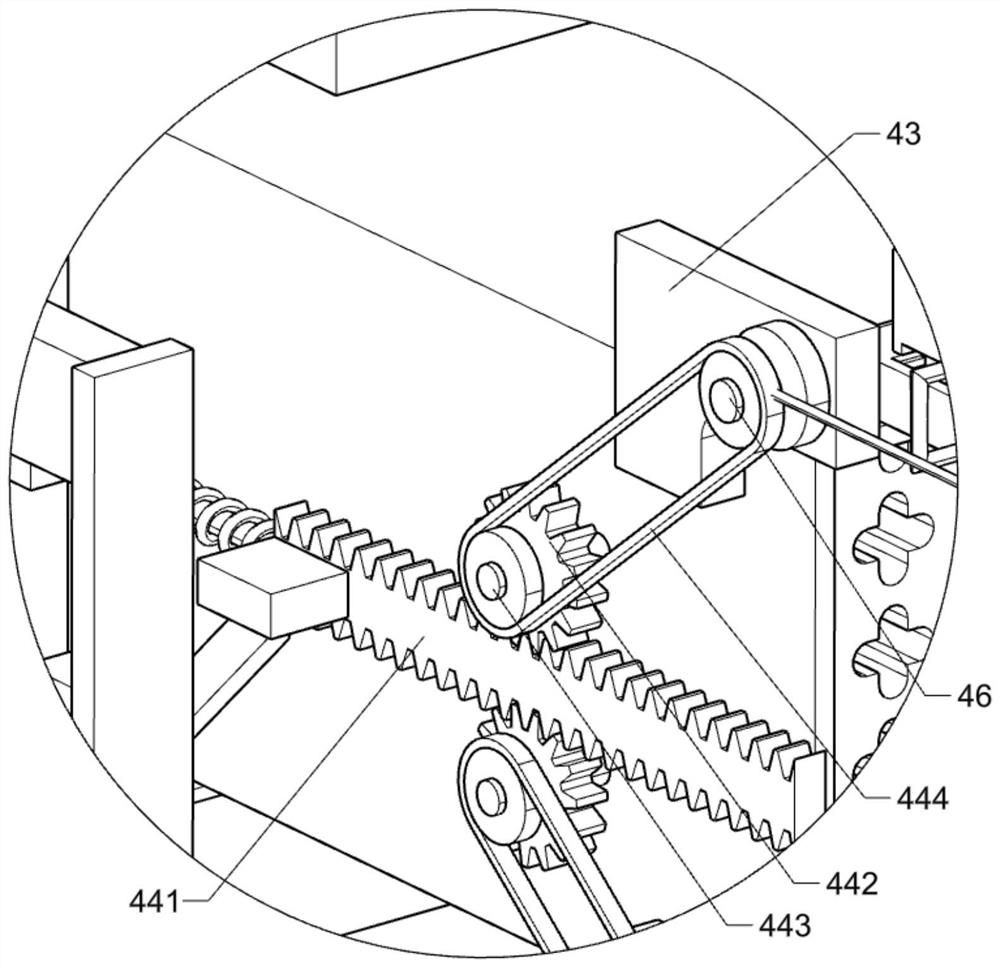

[0047] The first guide rod 15 will drive the first sliding block 41 to move, so that the muffler shell 4 will move, and then the muffler shell 4 will move to the position of the second port 12, and then the cross beam 45 will hit the blocking position 49, and then the fifth connecting rod 47 will drive the first rack 441 to move, the first rack 441 will move towards the direction of the first support plate 1, the first rack 441 will drive the first gear 442 to rotate, and then The first gear 442 drives the second rotating shaft 443 to rotate, the second rotating shaft 443 drives the first rotating shaft 46 to rotate through the transmission belt 444, and then the first rotating shaft 46 rotates on the second support plate 43, and the first rotating shaft 46 drives the rotating plate 5 to rotate After rotating, the rotating plate 5 will close the opening of the muffler shell 4,...

Embodiment 3

[0049] After the muffler body 42 is cleaned, it can return to the third port 13 for use again. If it needs to be shut down, it will reach the first port 11, and then the inside of the muffler body 42 will be kept sealed by the second sealing member 23.

Embodiment 4

[0051] When the muffler body 42 returns to the third port 13 after cleaning, the first rack 441 will be reset under the action of the second telescopic rod 48 and the first spring 481, so that the entire rotating plate 5, the second Two pipe fittings 6, cleaning structures 7 and 8 are reset, so that the baffle plate 54 is opened again, and then it will cooperate with the first cleaning rod 97 to clean up, and then the dustproof plate 61 will blow out air from the inside The fan blade 52 is cleaned by blowing, and then the fan blade 52 rotates to make the second pipe 6=baffle plate 54 clean the dustproof plate 61 to avoid the dustproof plate 61 from being blocked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com