Automatic calibration method of infrared camera

An automatic calibration and infrared camera technology, applied in the field of automatic calibration of infrared cameras, can solve problems such as excessive human factors, projection compression of calibration plate processing errors, etc., and achieve the effects of wide calibration occasions, difficult accuracy, and stable feature extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be explained in detail below in conjunction with the accompanying drawings and specific embodiments.

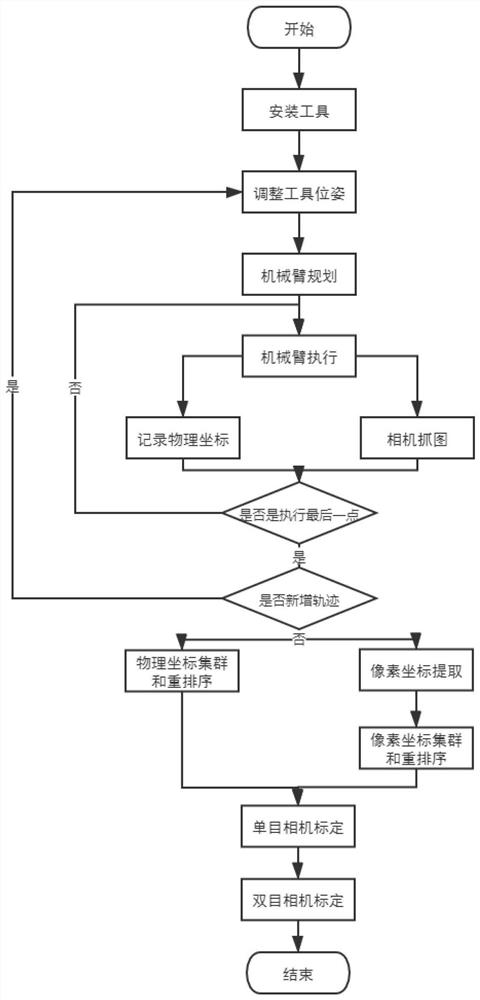

[0048] figure 1 Be the flow chart of infrared camera calibration method of the present invention, as figure 1 As shown, the automatic calibration method of the infrared camera of the present invention comprises the following steps:

[0049] (1) Fix the calibration tool to the end of the robotic arm;

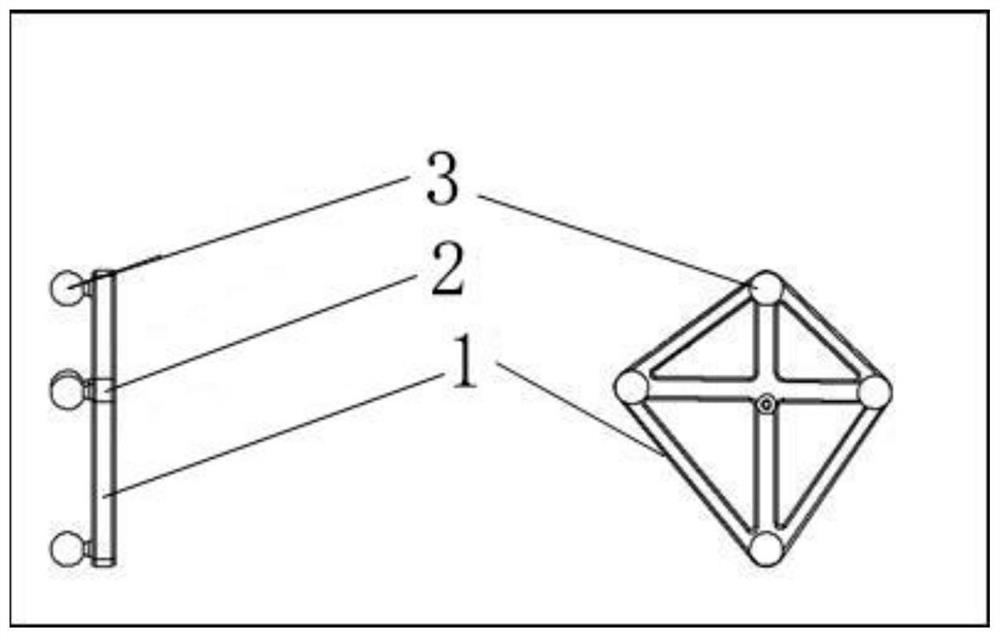

[0050] The calibration tool structure is as follows figure 2 As shown, at least three coplanar and non-collinear calibration objects 3 are fixed on the calibration tool;

[0051] Further, the calibration tool further includes an installation body 1 and fasteners 2 , the installation body 1 is fixed to the flange through common fasteners such as bolts, and the calibration object 3 is installed to the installation body 1 through the fasteners 2 .

[0052] Furthermore, the calibration object 3 is a reflective ball, and the surface of the refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com