Method for predicting service life of bearing of wind driven generator

A wind turbine and bearing life technology, applied in the field of bearing fault diagnosis, can solve the problem that the model is difficult to extract representation information, and achieve the effects of avoiding the change of data structure continuity, accurate remaining life, and accurate evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

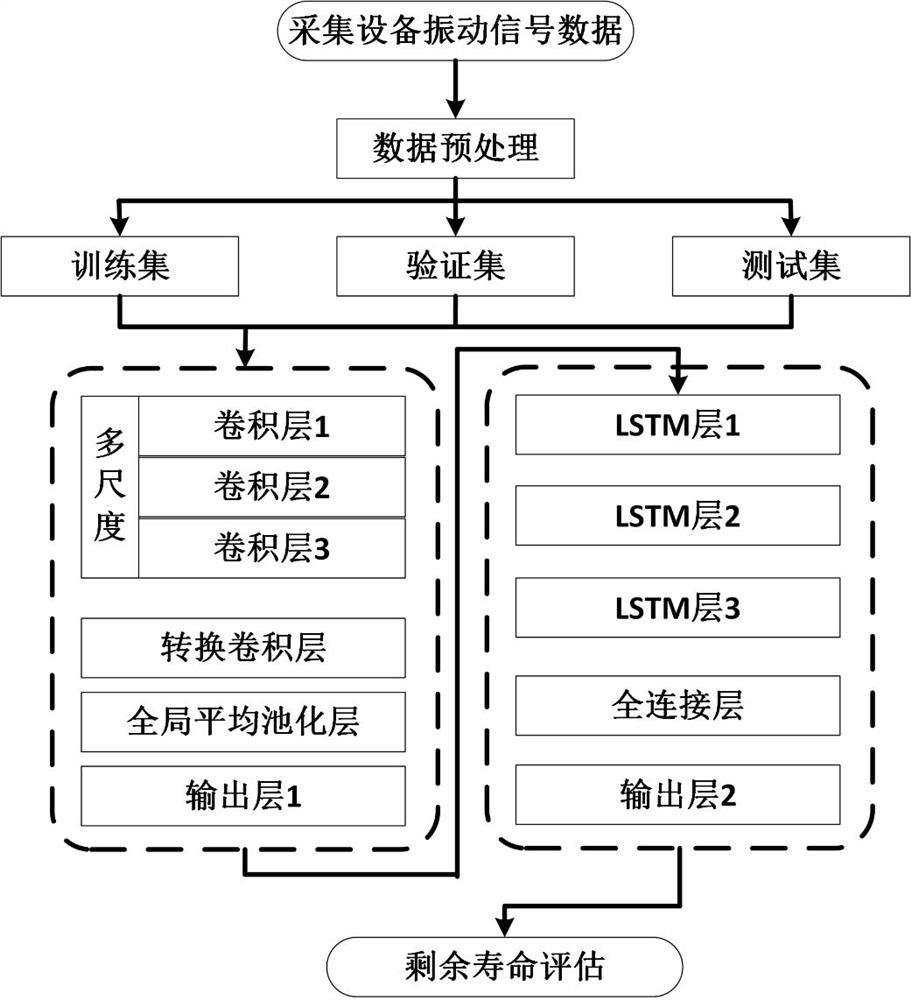

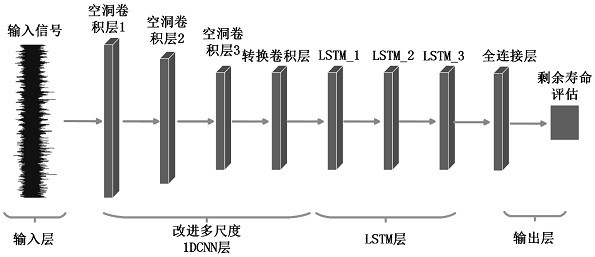

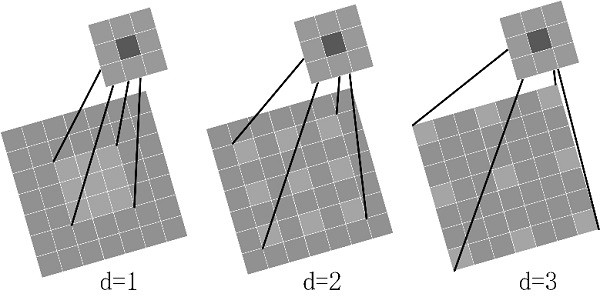

Method used

Image

Examples

Embodiment 1

[0068] The wind power generator bearing life prediction method provided in this embodiment is realized based on the rolling bearing accelerated life test platform, such as Figure 4 As shown, the experimental platform specifically includes:

[0069] The rolling bearing accelerated life experiment platform is composed of AC motor 1, motor speed controller 2, rotating shaft 3, support bearing 4, hydraulic loading system, test bearing 5, acceleration sensor 6 and data acquisition equipment 7, etc., and can be used to carry out various types of Test bearing experiments. The working conditions that can be adjusted by the platform mainly include radial force and rotational speed. The hydraulic loading system acts on the bearing housing to change the radial force of the bearing, and the motor speed is controlled and adjusted by the motor speed controller. The experimental bearing is LDK UER204 rolling bearing, and the detailed parameter information is shown in Table 1.

[0070] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com