Smelting reduction furnace main body welding platform and construction method thereof

A welding platform and reduction furnace technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficulty in building a support structure and complex support structure, and achieve the effect of convenient movement adjustment and small facility volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

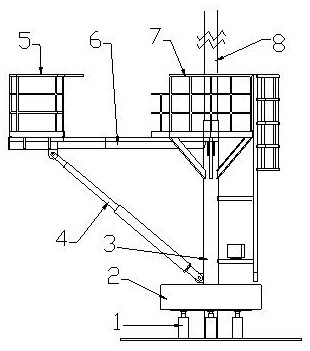

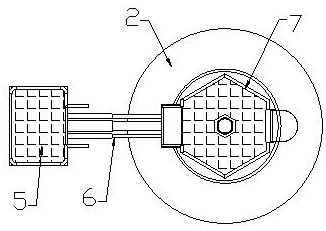

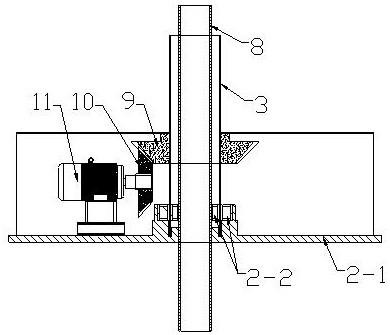

[0034] see figure 1 , figure 2 , The main body welding platform of the smelting reduction furnace provided by the present invention includes a central platform 7 and a working platform 5 arranged at the center of the furnace body 12 . The working platform 5 is connected with the central platform 7 through the telescopic beam 6, and the working platform 5 is arranged beside the welding seam 13 of the furnace body. A base 2 is provided at the bottom of the central platform 7, and a hydraulic jacking system is provided at the bottom of the base.

[0035] The hydraulic jacking system 1 of the present invention is used to realize the height adjustment of the central platform 7 and the working platform 5 . It is alwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com