Pressing quantitative essence lotion bottle

A technology of essence lotion and liquid bottle, applied in the directions of bottle, liquid treatment, bottle filling, etc., can solve the problems of large space, difficult to control the liquid output, easy to pour out a large amount of emulsion, etc., to avoid waste, tightness and stability The effect of good performance and accurate control of liquid output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

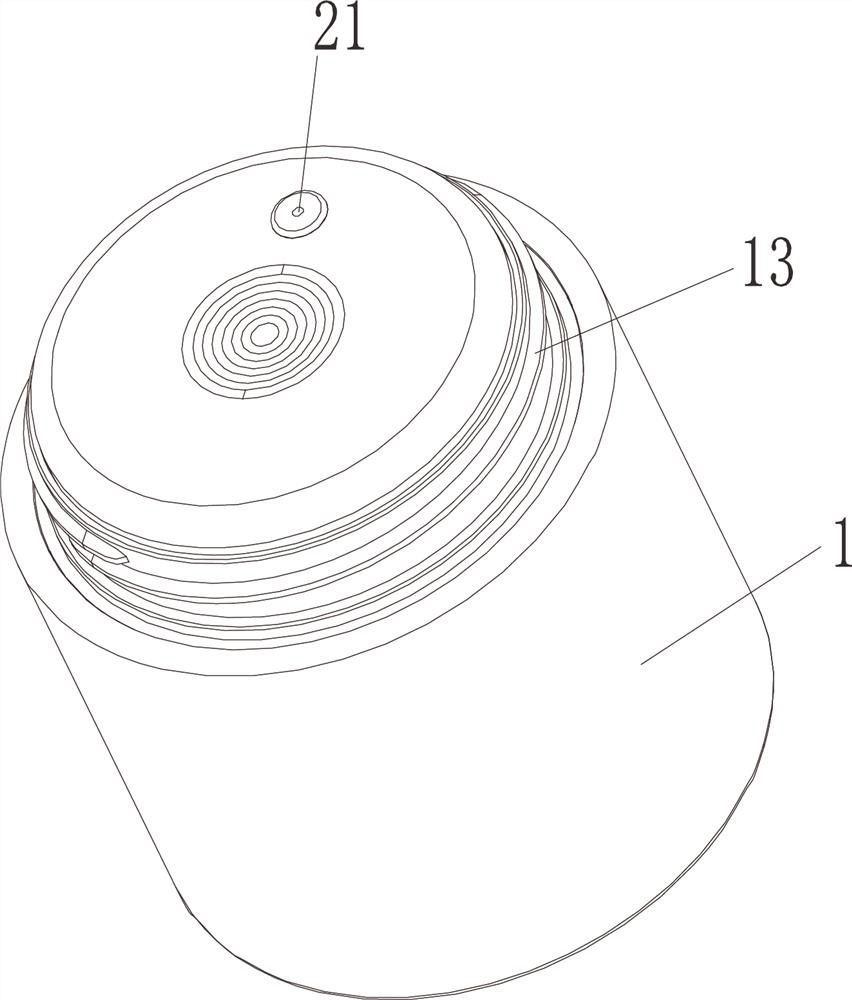

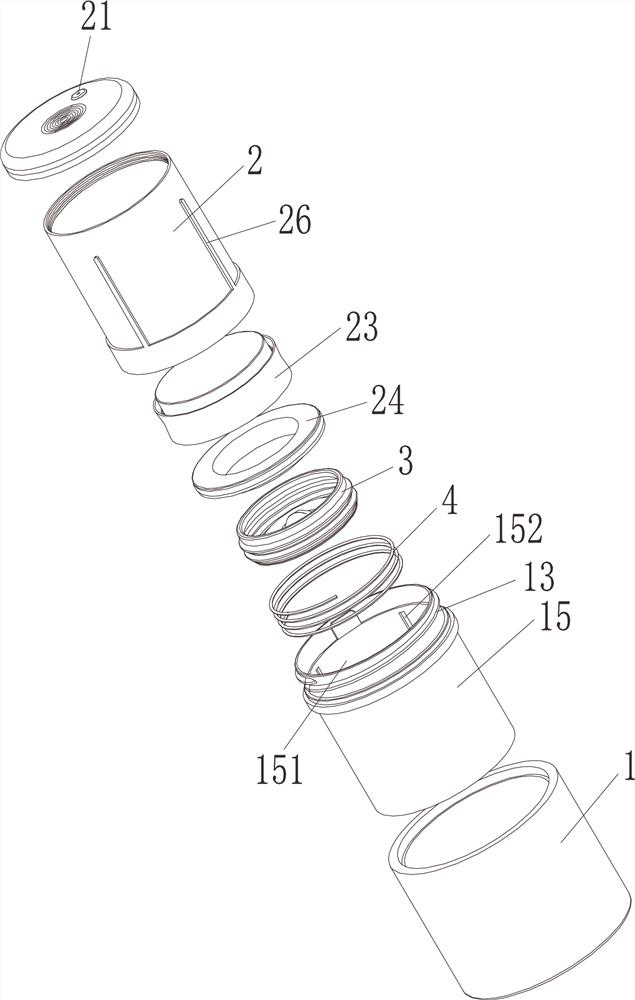

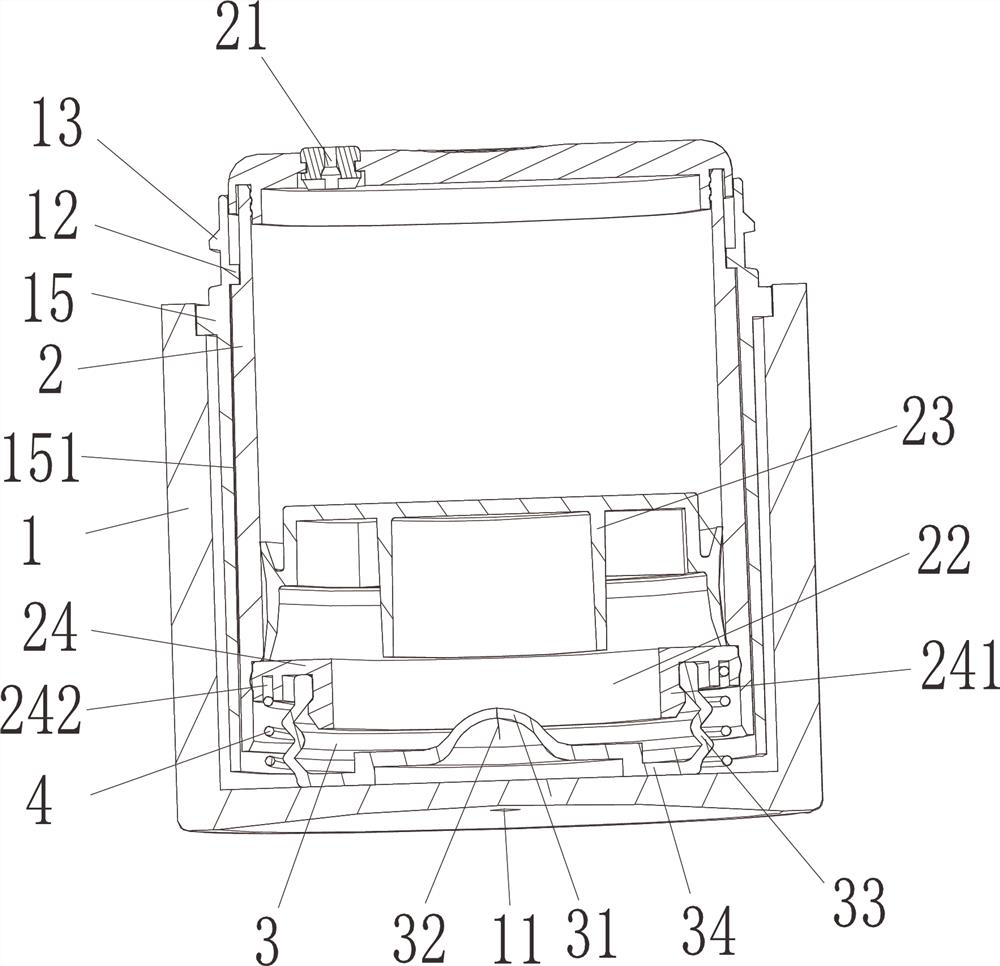

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 3 , Embodiment 1, a pressing quantitative essence lotion bottle, comprising an outer bottle body 1 and an inner bottle body 2, the inner bottle body 2 is slidably arranged in the outer bottle body 1, and the top of the inner bottle body 2 is provided with a liquid outlet 21, The bottom of the inner bottle body 2 is provided with an air inlet channel 22, the inner bottle body 2 is provided with a piston 23, and a liquid storage chamber is formed between the piston 23 and the liquid outlet 21, and an elastic air bag 3 is arranged on the outer peripheral sealing sleeve of the air inlet channel 22, which is elastically The bottom of the airbag 3 is against the outer bottle body 1, and the bottom of the elastic airbag 3 is provided with a raised portion 31 facing the direction of the air inlet channel 22. The raised portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com