Combined gravure rotary press

A printing machine and combined technology, applied in the directions of sending objects, stacking receiving devices, thin material handling, etc., can solve the problems of sub-stack storage and increase the difficulty of storage of printed products, so as to improve the quality, reduce the difficulty of storage, and improve the use of effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

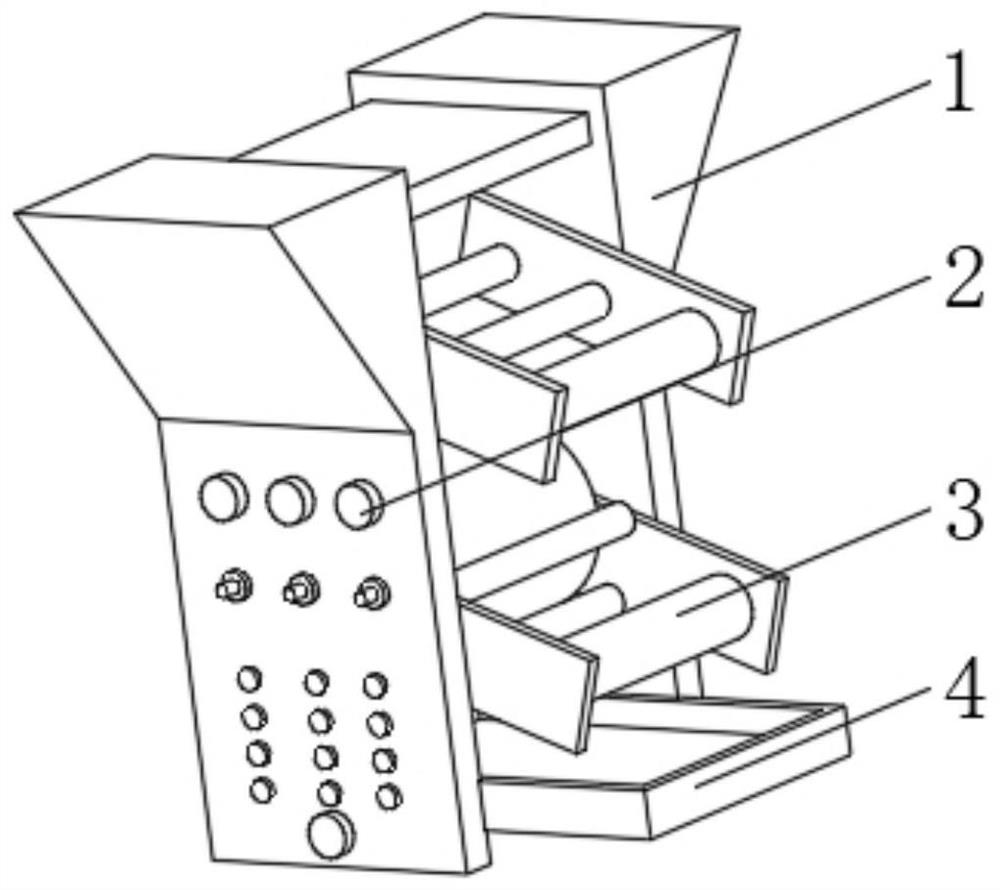

Embodiment 1

[0033] see Figure 1-4 , the present invention provides a technical solution: a combined gravure rotary printing machine, comprising a printing machine main body 1, a control button 2 is arranged on one side of the printing machine main body 1, a printing roller 3 is arranged on one side of the printing machine main body 1, Between the two sides of the main body 1 of the printing machine, a material receiving box 4 is arranged under the printing roller 3, and the inside of the material receiving box 4 is provided with:

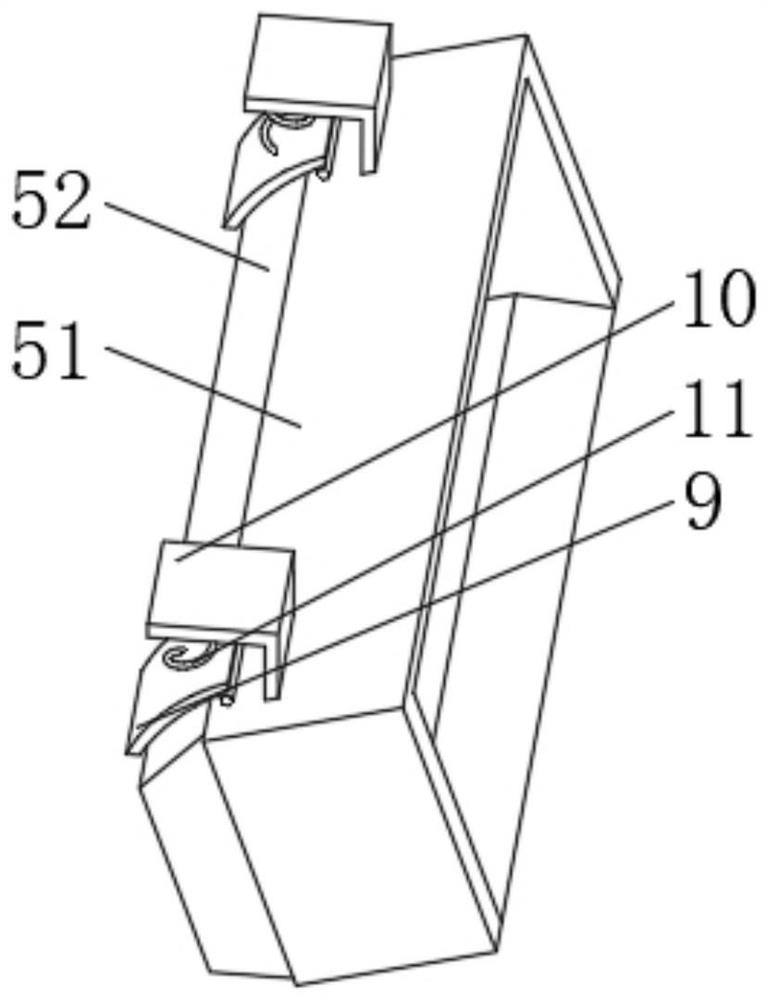

[0034] A shunt device 5, the shunt device 5 has a limiting frame 51, one end of the limiting frame 51 is provided with a rubber ring 52, and the inner top of the rubber ring 52 is symmetrically provided with a protective frame 53;

[0035] The guide device 7 , the guide device 7 has a metal bar 71 , both ends of the metal bar 71 are arc-shaped, and the metal bar 71 is slidably connected to the inner wall of the rubber ring 52 .

[0036] The inner top of the r...

Embodiment 2

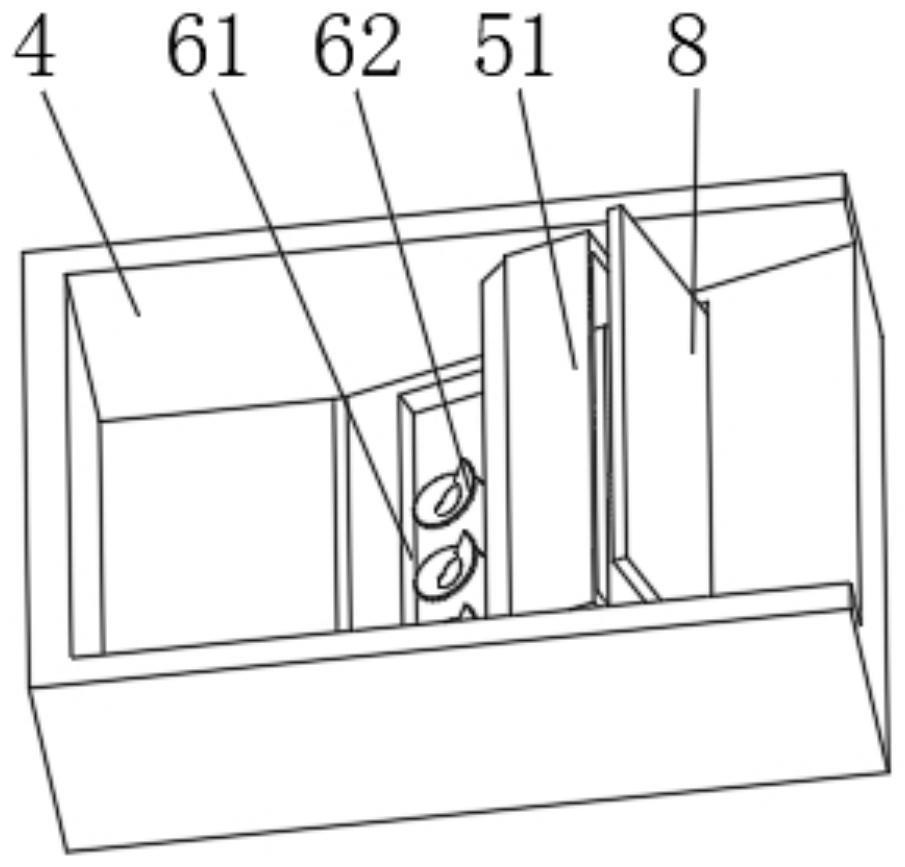

[0042] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 1, a buffer device 6 is provided inside the receiving box 4, and the buffer device 6 has a buffer groove 61, and the inner bottom of the buffer groove 61 is evenly provided with spiral elastic pieces 62 , The top of the helical shrapnel 62 is provided with a ventilation hole 63 .

[0043] An elastic plate 8 is disposed on the inner bottom of the buffer groove 61 , and the elastic plate 8 extends to the outside of the buffer groove 61 and is slidably connected with the limiting frame 51 .

[0044] The inner bottom of the buffer tank 61 is provided with a lifting rod 12 , the lifting rod 12 passes through the air hole 63 and extends above the spiral elastic piece 62 , and the outer side of the lifting rod 12 is provided with an arc-shaped elastic piece 13 .

[0045] The lifting rod 12 runs through the material receiving box 4 and extends to the outside of the material receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com