Environment-friendly dry powder foaming agent for shield construction and preparation method thereof

An environmentally friendly, foaming agent technology, applied in chemical instruments and methods, mining equipment, earth-moving drilling, etc., can solve problems such as difficulty in meeting construction requirements, small adjustable half-life range, etc., to reduce friction and improve tunneling efficiency. , Improve the effect of cohesion and flow plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to the mass ratio, weigh sodium lauryl sulfate and sodium lauryl alcohol polyoxyethylene ether sulfate and mix them in a ratio of 1:1; weigh polyethylene oxide and guar gum in a mass ratio of 2:1 Weighing, weigh lauryl alcohol and sodium carboxymethyl cellulose at the same time according to the ratio of 2:1, after they are mixed evenly, mix the foaming agent, thickener and foam stabilizer according to the mass ratio of 1:1 :1 ratio to obtain respectively; then add foaming agent to pure water and stir, after stirring evenly, add thickener and foam stabilizer in turn, the speed of stirring is controlled at 80r / min, then dry, pulverize and After sieving, a dry powdery substance was obtained.

Embodiment 2

[0031] According to the mass ratio, weigh sodium lauryl sulfate and sodium lauryl alcohol polyoxyethylene ether sulfate and mix them in a ratio of 2:1; weigh polyethylene oxide and guar gum according to a mass ratio of 2:1. Weighing, weigh lauryl alcohol and sodium carboxymethyl cellulose at the same time according to the ratio of 2:1, after they are mixed evenly, mix the foaming agent, thickener and foam stabilizer according to the mass ratio of 1:1 :1 ratio to obtain respectively; then add foaming agent to pure water and stir, after stirring evenly, add thickener and foam stabilizer in turn, the speed of stirring is controlled at 80r / min, then dry, pulverize and After sieving, a dry powdery substance was obtained.

Embodiment 3

[0033] According to the mass ratio, weigh sodium lauryl sulfate and sodium lauryl polyoxyethylene ether sulfate and mix them in a ratio of 1:3; weigh polyethylene oxide and guar gum in a mass ratio of 2:1 Weighing, weigh lauryl alcohol and sodium carboxymethyl cellulose at the same time according to the ratio of 2:1, after they are mixed evenly, mix the foaming agent, thickener and foam stabilizer according to the mass ratio of 1:1 :1 ratio to obtain respectively; then add foaming agent to pure water and stir, after stirring evenly, add thickener and foam stabilizer in turn, the speed of stirring is controlled at 80r / min, then dry, pulverize and After sieving, a dry powdery substance was obtained.

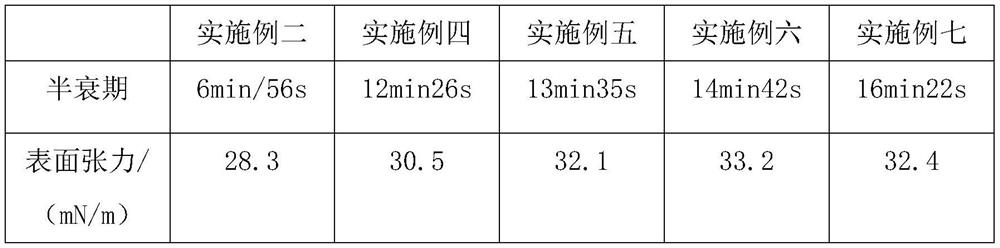

[0034] Dissolve the dry powders obtained in the above three examples in pure water, mix them according to the ratio of 3:7, use them after stirring evenly, add them to the corresponding foaming device for related tests, and the results are shown in the following table:

[0035] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap