A kind of smelting method of fecrconial high entropy alloy

A high-entropy alloy and smelting method technology, which is applied in the control of molten metal pouring from the casting ladle, improving energy efficiency, metal processing equipment, etc. Cleanliness has a greater impact on issues such as reducing smelting time, avoiding chemical reactions, and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

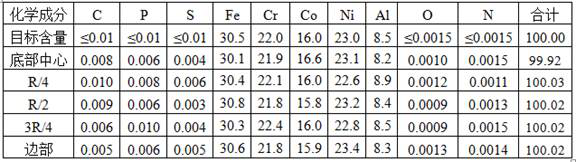

[0036] FeCrCoNiAl high-entropy alloys are smelted in a vacuum induction furnace with a rated capacity of 50kg. The raw materials used are electrolytic nickel (content 99.98%), electrolytic cobalt (content 99.99%), metal chromium (content 99.6%), pure iron (content 99.5%), aluminum The chemical composition and target content of FeCrCoNiAl high-entropy alloy are shown in Table 1. Its production steps include:

[0037] (1) alloy premelting:

[0038] ①After polishing the surface oxide layer of electrolytic nickel and electrolytic cobalt, bake electrolytic nickel, electrolytic cobalt and metallic chromium in an argon furnace at 150℃ for 6 hours;

[0039] ② Put 13.8kg of electrolytic nickel into the vacuum induction furnace zirconia prefabricated crucible, and 9.6kg of electrolytic cobalt and 13.2kg of metallic chromium into the sub-silo; evacuate to 5Pa, energize and melt;

[0040] ③ After melting, add metal chromium in 4 batches. The amount of metal chromium added in each batch ...

Embodiment 2

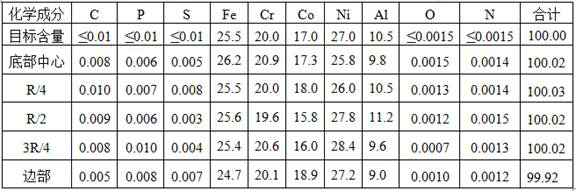

[0055] FeCrCoNiAl high-entropy alloys are smelted in a vacuum induction furnace with a rated capacity of 100kg. The raw materials used are electrolytic nickel (content 99.98%), electrolytic cobalt (content 99.99%), metal chromium (content 99.6%), pure iron (content 99.5%), aluminum The chemical composition and target content of FeCrCoNiAl high-entropy alloy are shown in Table 2. Its production steps include:

[0056] (1) alloy premelting:

[0057] ①After polishing the surface oxide layer of electrolytic nickel and electrolytic cobalt, bake electrolytic nickel, electrolytic cobalt and metallic chromium in argon furnace at 200℃ for 5h;

[0058] ② 31.2kg of electrolytic nickel is loaded into the vacuum induction furnace zirconia prefabricated crucible, and 21.6kg of electrolytic cobalt and 24.0kg of metallic chromium are loaded into the sub-silo; evacuated to 3Pa, energized and melted;

[0059] ③ After melting, add metal chromium in 4 batches, and the amount of metal chromium add...

Embodiment 3

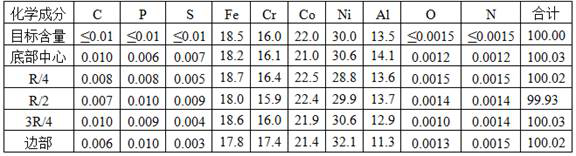

[0074] FeCrCoNiAl high-entropy alloys are smelted in a vacuum induction furnace with a rated capacity of 500kg. The raw materials used are electrolytic nickel (content 99.98%), electrolytic cobalt (content 99.99%), metal chromium (content 99.6%), pure iron (content 99.5%), aluminum The chemical composition and target content of FeCrCoNiAl high-entropy alloy are shown in Table 3. Its production steps include:

[0075] (1) alloy premelting:

[0076] ①After polishing the surface oxide layer of electrolytic nickel and electrolytic cobalt, bake electrolytic nickel, electrolytic cobalt and metallic chromium in 180℃ argon furnace for 6 hours;

[0077] 2. 180kg of electrolytic nickel is loaded into the vacuum induction furnace zirconia prefabricated crucible, and 132kg of electrolytic cobalt and 96kg of metallic chromium are loaded into the sub-silo; evacuated to 1Pa, energized and melted;

[0078] ③ After melting, add metal chromium in 10 batches. The amount of metal chromium added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com