Large size ni-cr electrothermal alloy billet and hot working method

An electrothermal alloy, large-scale technology, applied in the field of electrothermal alloy blanks and large-scale Ni-Cr electrothermal alloy blanks, can solve the problems of undisclosed alloy blank size, undisclosed thermal processing parameters and control points, etc., to improve the yield and Final product trial performance, reducing subsequent use costs, and meeting the effects of preparation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

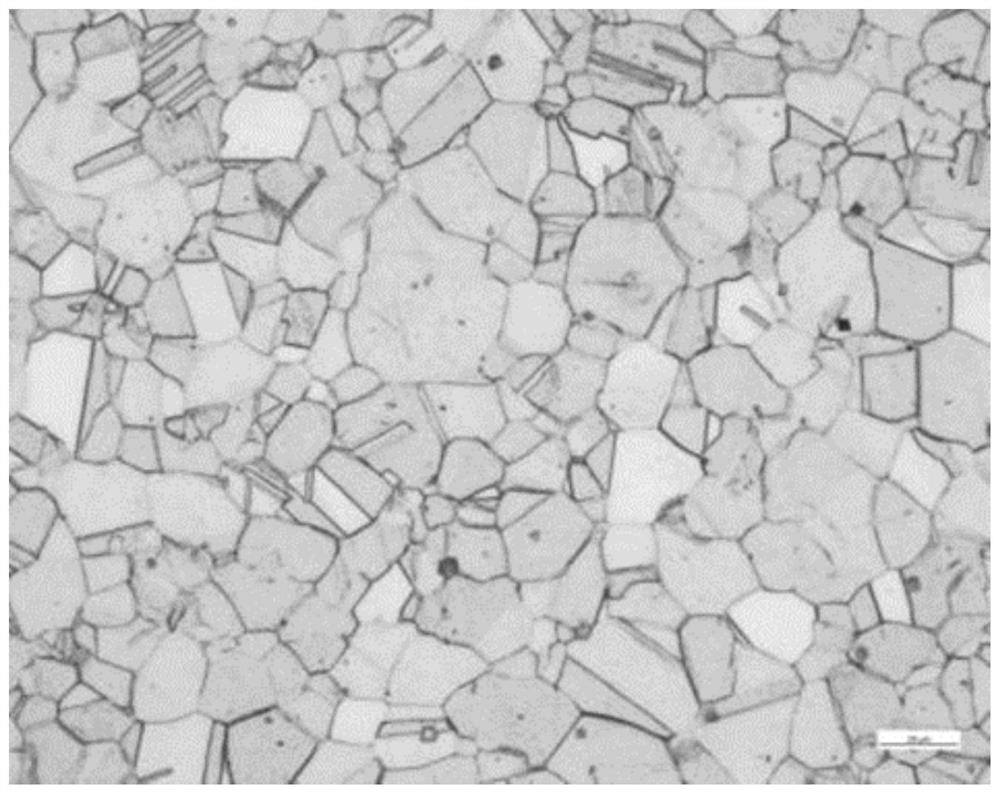

Image

Examples

specific Embodiment

[0026] The main purpose of the present invention is to provide a hot working method for large-scale Ni-Cr electrothermal alloy blanks aiming at the deficiencies of the existing production technology. The method can prepare high-quality and large-scale Ni-Cr electrothermal alloy blanks, meet the preparation requirements of electrothermal devices for high-power industrial electric furnaces, and improve the yield of blanks in the production process.

[0027] In the present invention, "large size" refers to blanks with a single weight exceeding 800kg unless otherwise specified.

[0028] The object of the present invention is mainly achieved through the following technical solutions:

[0029] A hot working method for a large-sized Ni-Cr electrothermal alloy blank, the method mainly comprises the following steps:

[0030] 1. Billet preparation: use vacuum induction melting + electroslag remelting to prepare Ni-Cr electrothermal alloy electroslag round ingots with a unit weight of m...

Embodiment 1

[0036] The scheme of the present invention can be further elaborated and understood by the following examples:

[0037] The large-scale Cr20Ni80 hot working of the embodiment is carried out according to the following method:

[0038] 1. Billet preparation: use vacuum induction melting + electroslag remelting to prepare Ni-Cr electrothermal alloy electroslag round ingots with a unit weight of more than 1.2 tons. The material composition is controlled as (mass percentage): C≤0.05%, Si 0.9-1.60%, Al≤0.50%, Cr20.0-22.0%, Mn≤0.3%, Fe≤1.0%, P≤0.010%, S≤ 0.010%, Ti≤0.01%, Zr 0.1-0.25%, Re≤0.2%, the balance is Ni and inevitable impurities. The diameter of the ingot after electroslag is 350±10mm.

[0039] 2. Fast forging: (1) Heating: The Ni-Cr electrothermal alloy is heated in stages. The heating rate is about 150°C / h during the heating process. The first stage is heated to 830±10°C and kept for about 2.5h; Then continue to heat up to 1135±10℃, and keep for 4-6h; (2) Forging: the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com