Drop hammer impact testing machine for testing non-metallic materials

A drop weight impact test, non-metallic material technology, applied in the direction of analysis of materials, measuring devices, instruments, etc., can solve the problems of time-consuming operation, broken and splashed, inconvenient plates, etc., achieve convenient loading and unloading operations, and improve test efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

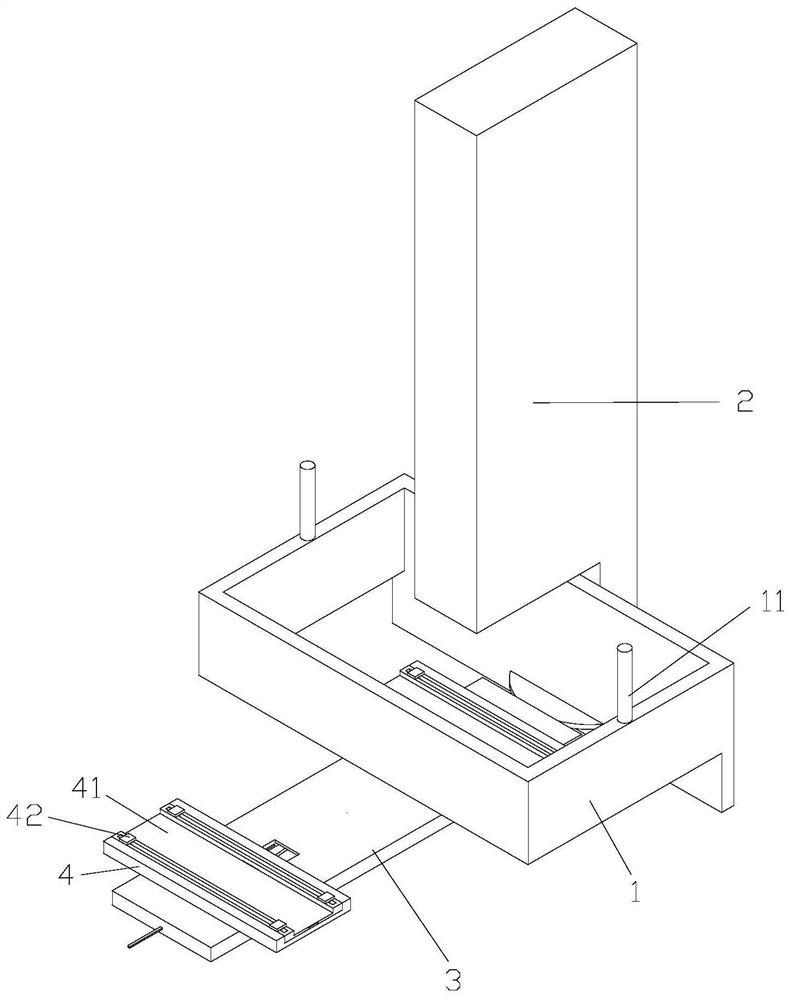

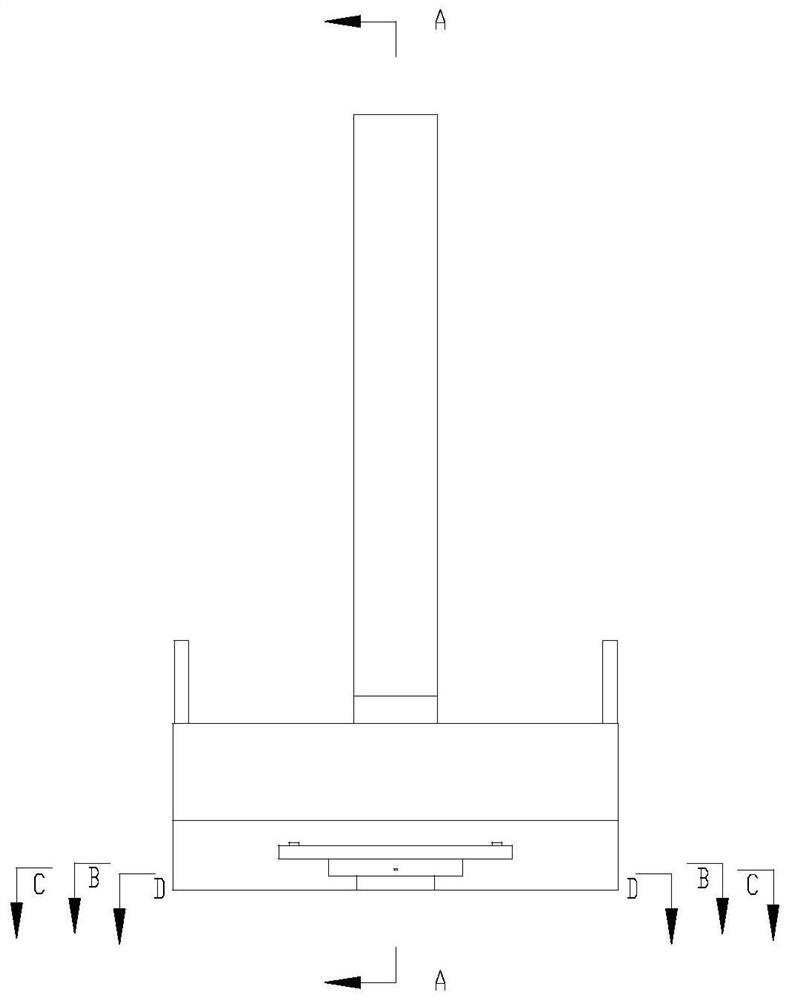

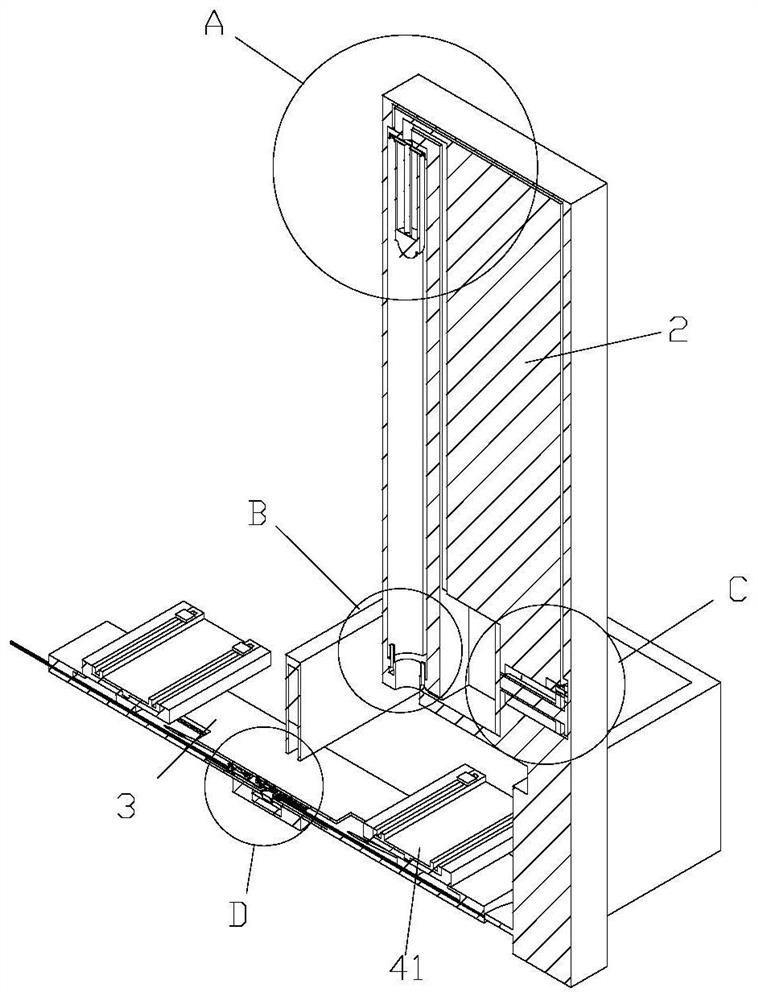

[0044] Such as Figure 1-28 As shown, a drop weight impact testing machine for testing non-metallic materials includes a box body 1, a guide rod 2 arranged on the side wall of the box body 1, and a drop weight 21 arranged on the guide rod 2. The bottom of the box 1 is provided with an opening, one side of the box 1 is provided with a base 5, the base 5 is provided with a first connecting plate 3, and the two ends of the first connecting plate 3 are respectively provided with a loading plate 41 , the base 5 is provided with a first motor 51 for driving the rotation of the first connecting plate 3, and the first motor 51 can drive the carrier plate 41 to move on the first connecting plate 3, so The top of the opening is provided with a first movable groove, and a partition 13 is arranged in the first movable groove, and a cylinder 11 for driving the partition 13 to move up and down is provided on the box body 1; Each end is equipped with a loading plate, when the loading plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com