Dynamic circulation liquid metal environmental material corrosion test system

A technology of liquid metal and dynamic circulation, which is applied in the direction of analyzing materials, weather resistance/light resistance/corrosion resistance, testing wear resistance, etc., can solve problems such as the inability to realize liquid metal flow and stress loading, and achieve purification of impurities and stability The effect of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

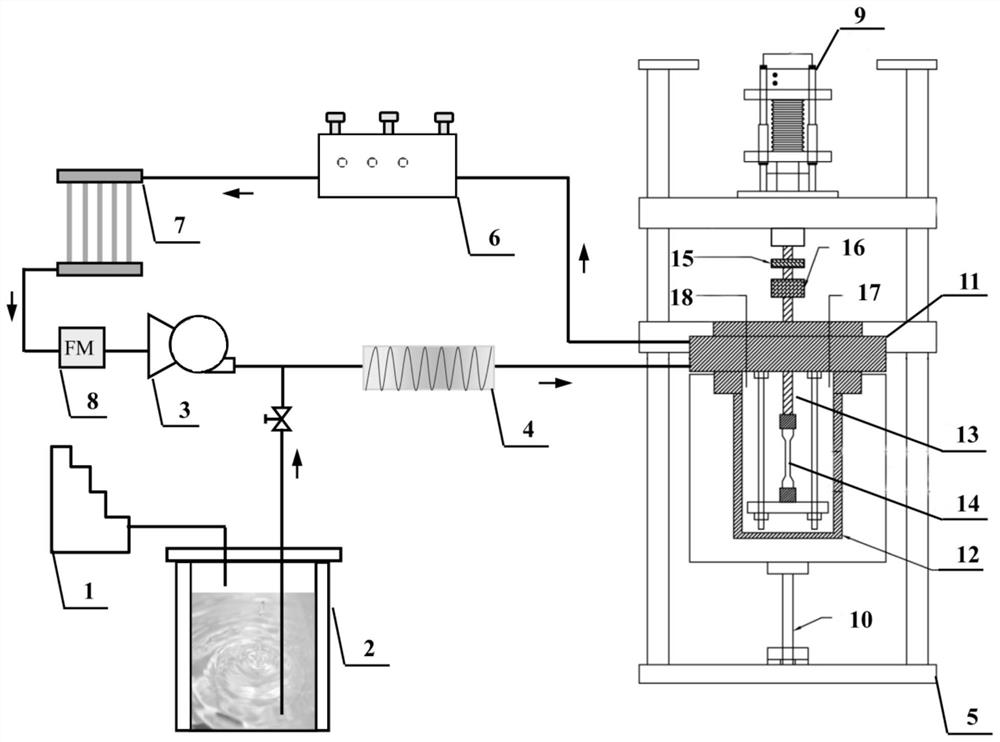

[0031] Such as figure 1 As shown, a dynamic circulation liquid metal environment material corrosion test system provided by the embodiment of the present invention is mainly composed of a gas pump 1, a melting storage tank 2, a circulation pump 3, a heater 4, a stress corrosion device 5, and an oxygen control box 6. It is composed of air cooler 7, flow meter 8 and several pipelines and valves.

[0032] Among them, the melting storage tank 2 is used to heat and melt solid metal and store and recover the liquid metal in the test system; the upper end of the melting storage tank is connected to the gas pump 1 through a gas pipeline, and the bottom end is connected to the circuit of the test system through a pipeline; the melting storage tank The tank 2 is provided with a heating device, a liquid level measuring device and a gas interface; the heating device is used to melt solid metal, the liquid level measuring device is used to measure the metal liquid level in the molten stora...

Embodiment 2

[0040] An operating method of a dynamic circulation liquid metal environment material corrosion test system provided by an embodiment of the present invention includes the following steps:

[0041] (1) Sample assembly: start the kettle body lifting device 11, lower the kettle body 12, install the stress corrosion sample on the sample fixture, open the kettle body lifting device 10 again, lift the kettle body 12, and complete the kettle cover 11 and the fastening and sealing of the still body 12;

[0042] (2) Pipeline preheating: turn on the heat tracing switch of the loop pipeline to preheat the loop pipeline;

[0043] (3) Canned medium: through the gas pump 1, the test medium in the molten storage tank 2 is pressed into the test system loop through the valve;

[0044] (4) Loop operation: Turn on the circulation pump 3, and after the liquid metal medium obtains thrust, it flows out from the circulation pump 3 and then flows through the heater 4, the stress corrosion device 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com