Blast furnace gas cabinet position prediction method based on multi-factor analysis

A technology of blast furnace gas and prediction method, which is applied in prediction, neural learning method, instrument, etc., can solve the problems of frequent changes in equipment operating conditions and difficulty in accurately predicting the fluctuation of counters, so as to reduce modeling complexity and simplify model input. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

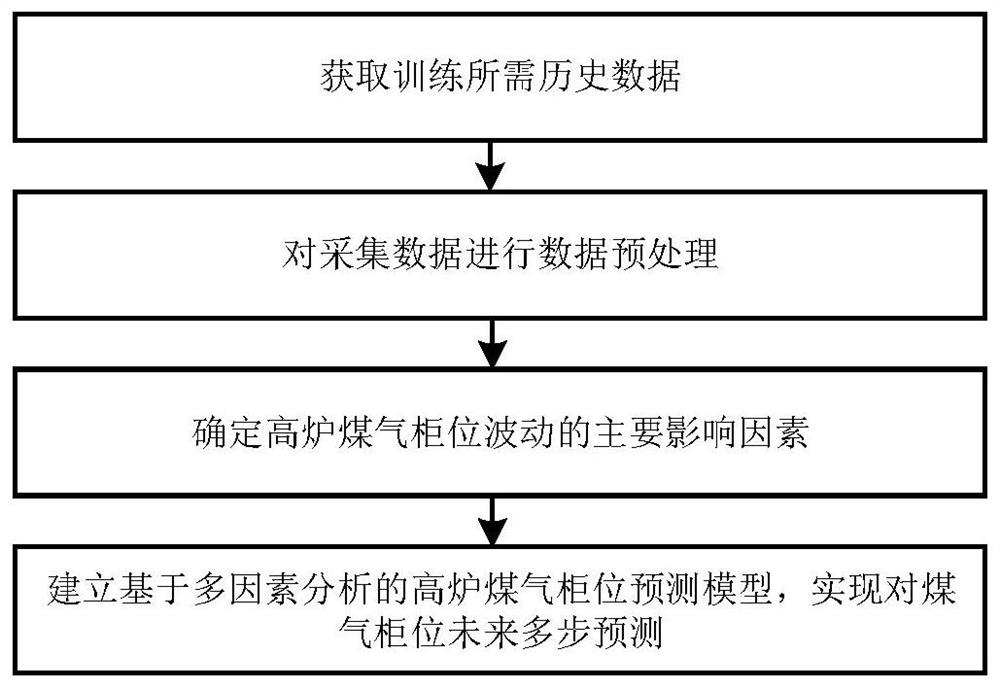

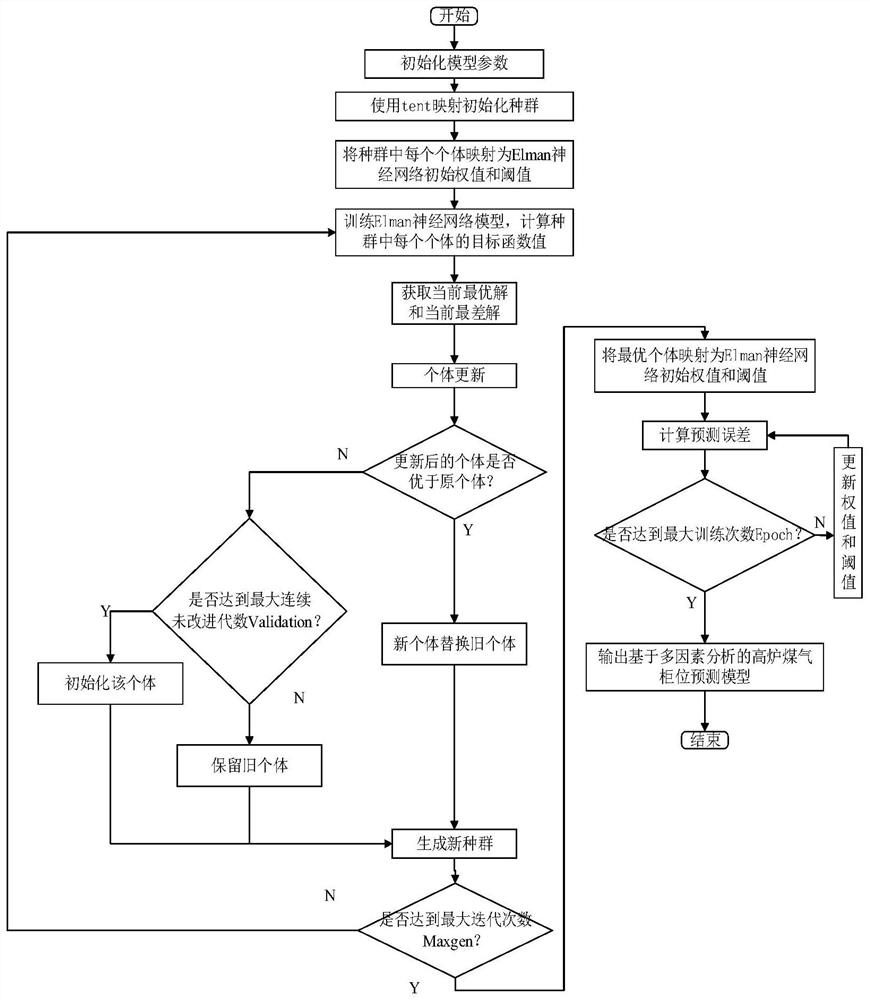

[0056] The following process takes the actual production data of the blast furnace gas system in the energy center of a large iron and steel enterprise as an example, and predicts the counter value of two blast furnace gas cabinets 30 minutes in advance, that is, predicts the counter value per minute for the next 30 minutes. The overall process is as figure 1 shown.

[0057] Step 1: Obtain the historical data required for training.

[0058] The data collected from the real-time database for nearly 3 months, the sampling interval is 1 minute, and the collected data include: blast furnace gas intake data of 1#~4# blast furnace; 1#~3# hot rolling production line, 1# Blast furnace gas consumption data of equipment in #, 2#, 5# cold rolling production line, rough rolling production line, 1#, 2# steel pipe production line, coke oven, 135T boiler,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com