Textile machine with plurality of identical stations

A technology of textile machines and workstations, applied in textile and papermaking, fiber processing safety devices, fiber processing and other directions, can solve the problems of lag in operator intervention, operators cannot identify immediately, and long downtime, etc., to optimize the walking distance, The effect of low cost and low profit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

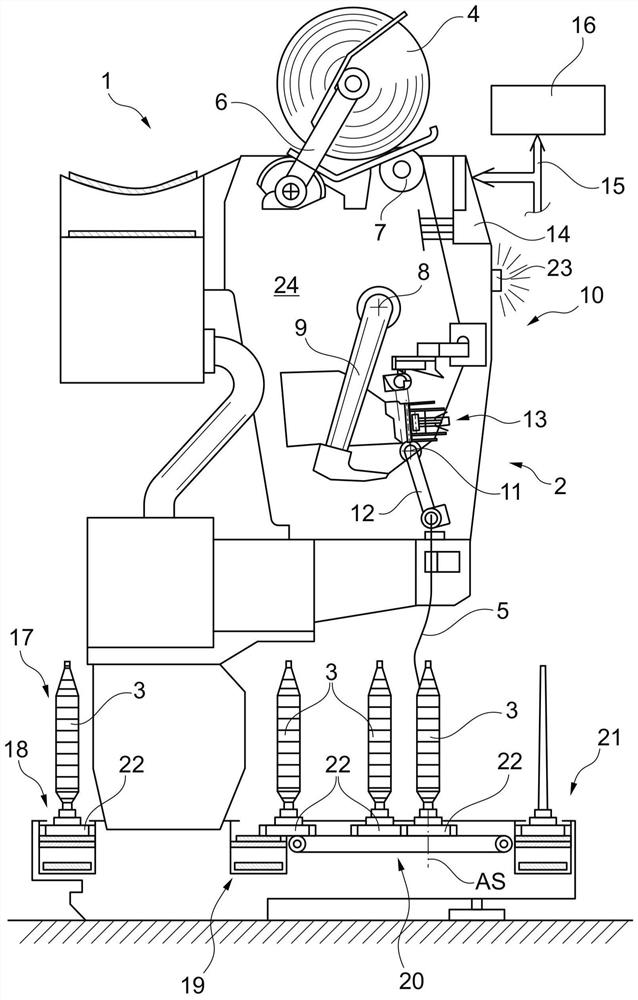

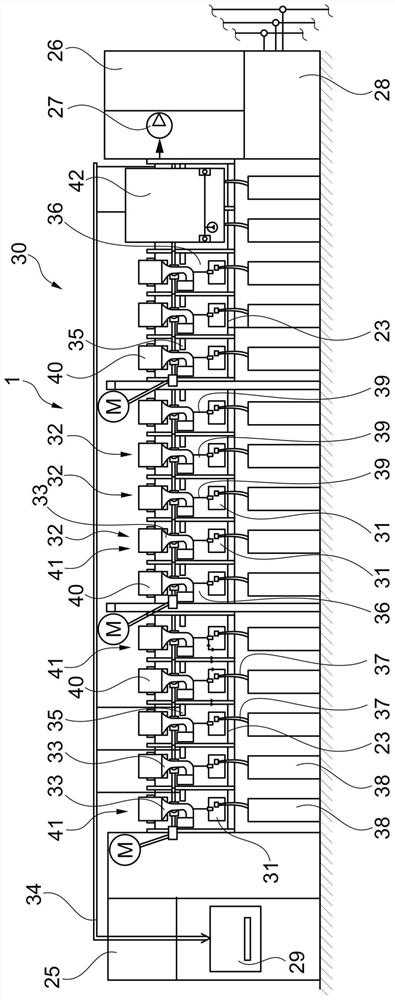

[0066] figure 1 and 2 An exemplary embodiment of a textile machine 1 is shown, each having a plurality of workstations 2 or 41 arranged side by side in rows. Station 2 or station 41 of textile machine 1 is designed identically here. here, figure 1 A textile machine 1 for producing cross-wound bobbins, a plurality of stations 2 arranged side by side of a cross-wound automatic winder 10 are shown in side view, while figure 2 The front view shows a textile machine 1 in the form of an open-end rotor spinning machine 30 producing cross-wound bobbins.

[0067] As is known, a spinning bobbin 3 produced in a ring spinning machine upstream in the production process and having relatively little yarn material is rewound at station 2 of the cross-winding automatic winder 10 Large packages are cross-wound on the bobbin 4, where the yarn 5 from the spinning bobbin 3 is also monitored for yarn defects during the rewinding process and removed immediately. As can be seen, the cross-wound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com