Food gas production detection method and detection kit thereof

A kit and food technology, applied in the direction of measuring devices, material analysis by observing the influence of chemical indicators, instruments, etc., can solve the problem of long inspection time (usually 30 days or even 60 days or more, and cannot be timely Feedback on issues such as microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] 1. Materials

[0101] The samples of different varieties of vinegar were provided by Wilmar (Shanghai) Biotechnology R&D Center Co., Ltd.

[0102] 2. Reagents

[0103] Reagents were purchased from Sinopharm Chemical Reagent Co., Ltd.

[0104] 3. Experimental method

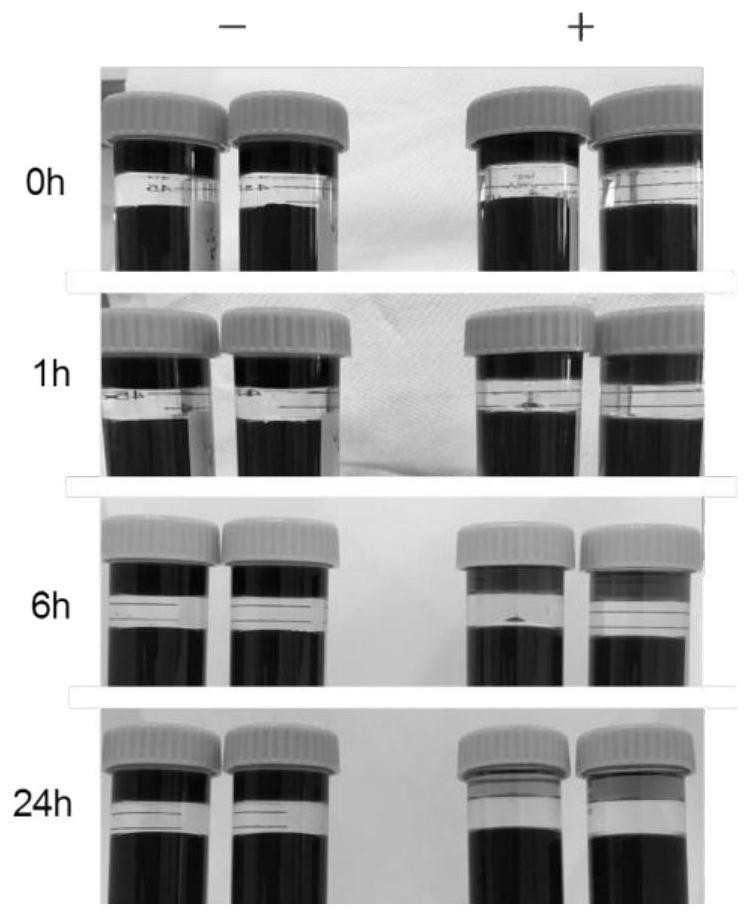

[0105] 3.1. Sampling

[0106] Shake normal vinegar and flatulence vinegar (the vinegar bottle swells and deforms before opening, and the vinegar comes out of gas after opening) and shake evenly, then open the bottle, take 40ml of vinegar and transfer them into 50ml centrifuge tubes.

[0107] 3.2. Oil seal

[0108] On top of the vinegar in the centrifuge tube, gently add 5ml of mineral oil to form an oil seal to prevent air from coming into contact with the vinegar. When adding, be careful to avoid air bubbles between the vinegar and the oil layer.

[0109] 3.3. Add indicator

[0110] After adding the oil layer on top of the vinegar, try not to shake, and gently add 5ml of the indicator on top of the ...

Embodiment 2

[0116] 1. Materials

[0117] The samples of different varieties of vinegar were provided by Wilmar (Shanghai) Biotechnology R&D Center Co., Ltd.

[0118] 2. Reagents

[0119] Reagents were purchased from Sinopharm Chemical Reagent Co., Ltd.

[0120] 3. Experimental method

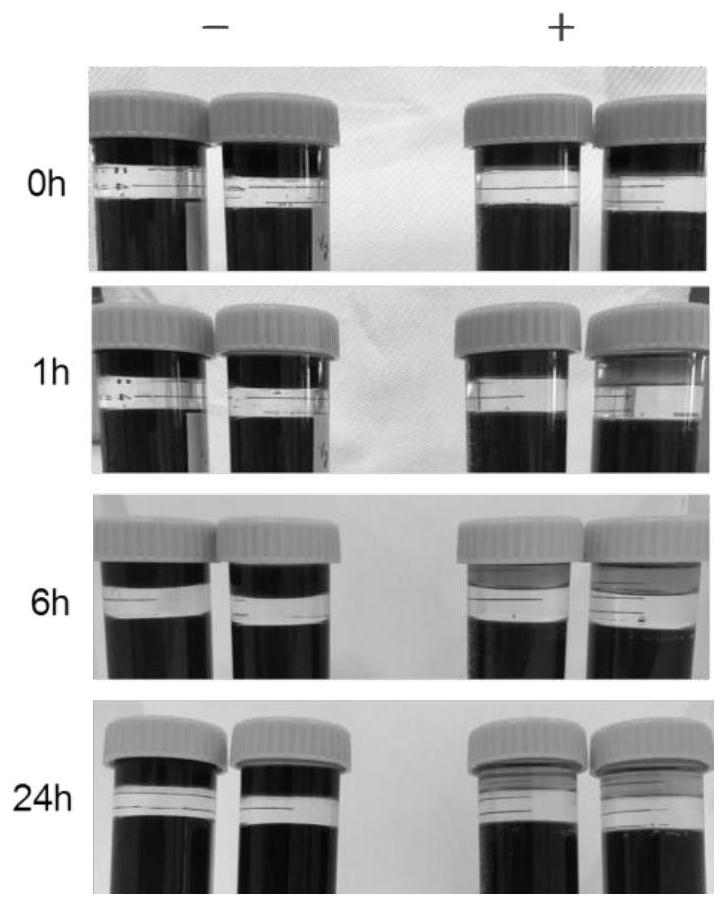

[0121] 3.1. Sampling

[0122] Shake normal vinegar and flatulence vinegar (the vinegar bottle expands and deforms before opening, and the vinegar ejected from gas after opening) shake evenly, open the bottle mouth, take 40ml of vinegar into 50ml centrifuge tubes respectively, and add the final mixture respectively 0.5% by weight total of sterilized glucose and peptone.

[0123] 3.2. Oil seal

[0124] Gently add 5ml of mineral oil on top of the vinegar in each centrifuge tube to form an oil seal to prevent air from coming into contact with the vinegar. When adding, be careful to avoid air bubbles between the vinegar and the oil layer.

[0125] 3.3. Add indicator

[0126] After adding the oil layer on...

Embodiment 3

[0215] 1. Materials

[0216] The samples of different varieties of vinegar were provided by Wilmar (Shanghai) Biotechnology R&D Center Co., Ltd.

[0217] 2. Reagents

[0218] Reagents were purchased from Sinopharm Chemical Reagent Co., Ltd.

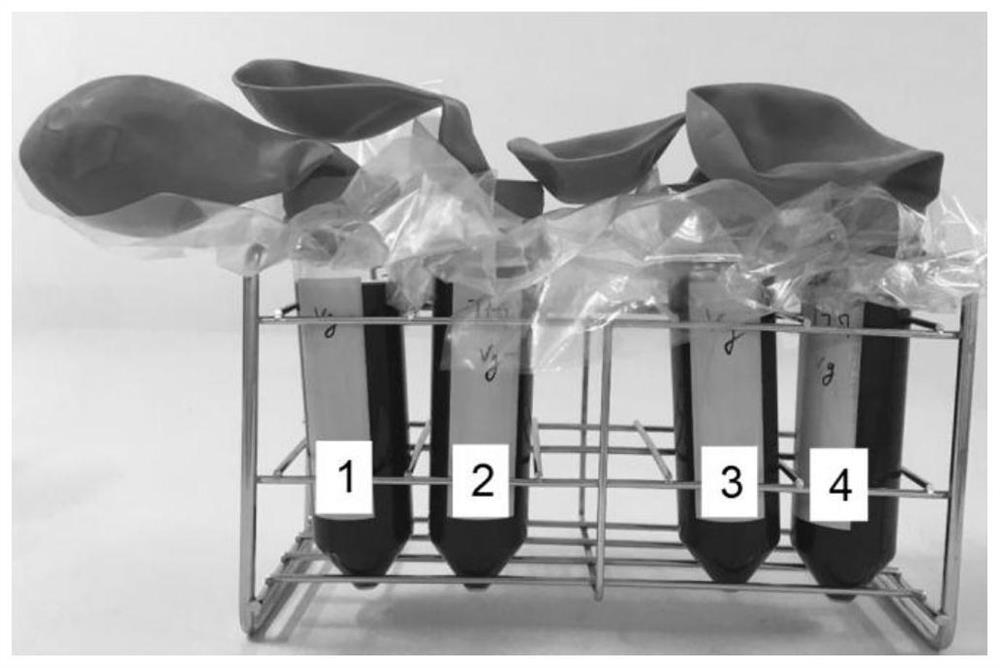

[0219] 3. Experimental method

[0220] Preparation of indicator solution: Weigh a certain amount of cresol red powder and dissolve it in ethanol to make a 0.02g / 100ml ethanol solution. Use NaOH solution to adjust the indicator solution from yellow to purple.

[0221] 3.1. Sampling

[0222] Shake normal vinegar and flatulence vinegar (the vinegar bottle swells and deforms before opening, and the vinegar comes out of gas after opening) and shake evenly, then open the bottle, take 25ml of vinegar and transfer them into 50ml centrifuge tubes.

[0223] 3.2. Oil seal

[0224] On top of the vinegar in the centrifuge tube, gently add 5ml of mineral oil to form an oil seal to prevent air from coming into contact with the vinegar. When addin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com