Regeneration method of filler of styrene polymerization inhibitor (TBC) removal tower

A technology of styrene and polymerization inhibitor, which is applied in the field of regeneration of styrene polymerization inhibitor removal tower packing, can solve problems such as reducing work efficiency, and achieve the effects of improving efficiency, improving adsorption effect, and increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

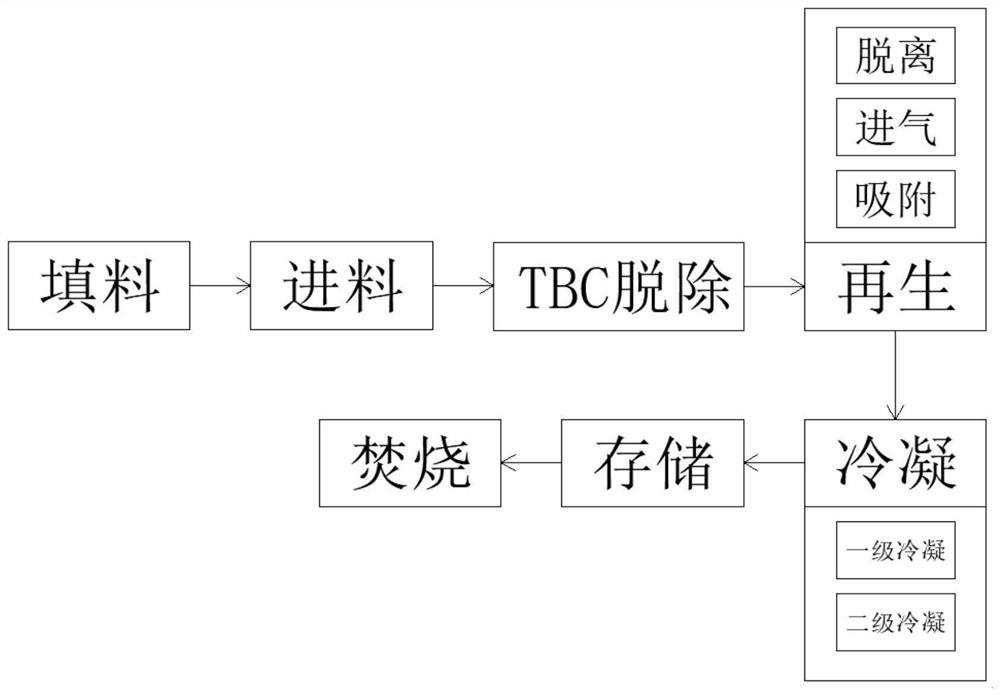

[0051] see Figure 1-9 , a kind of styrene polymerization inhibitor (TBC) removes the regeneration method of tower filler, comprises the following steps:

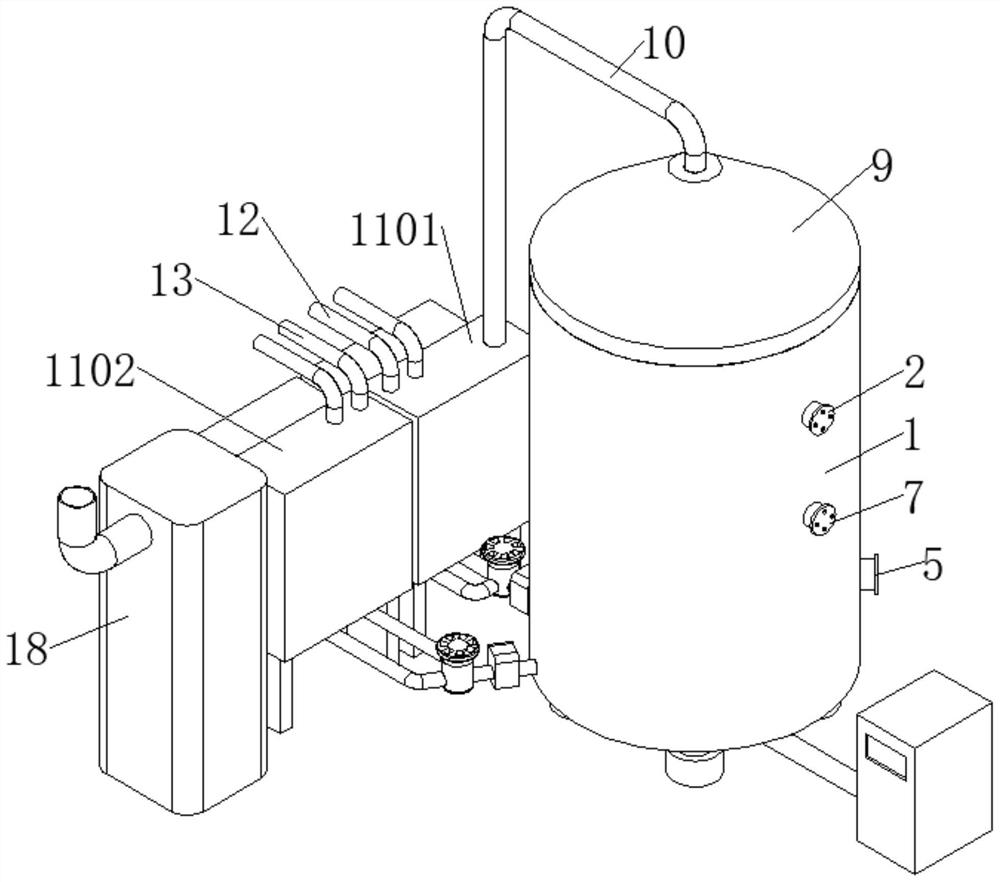

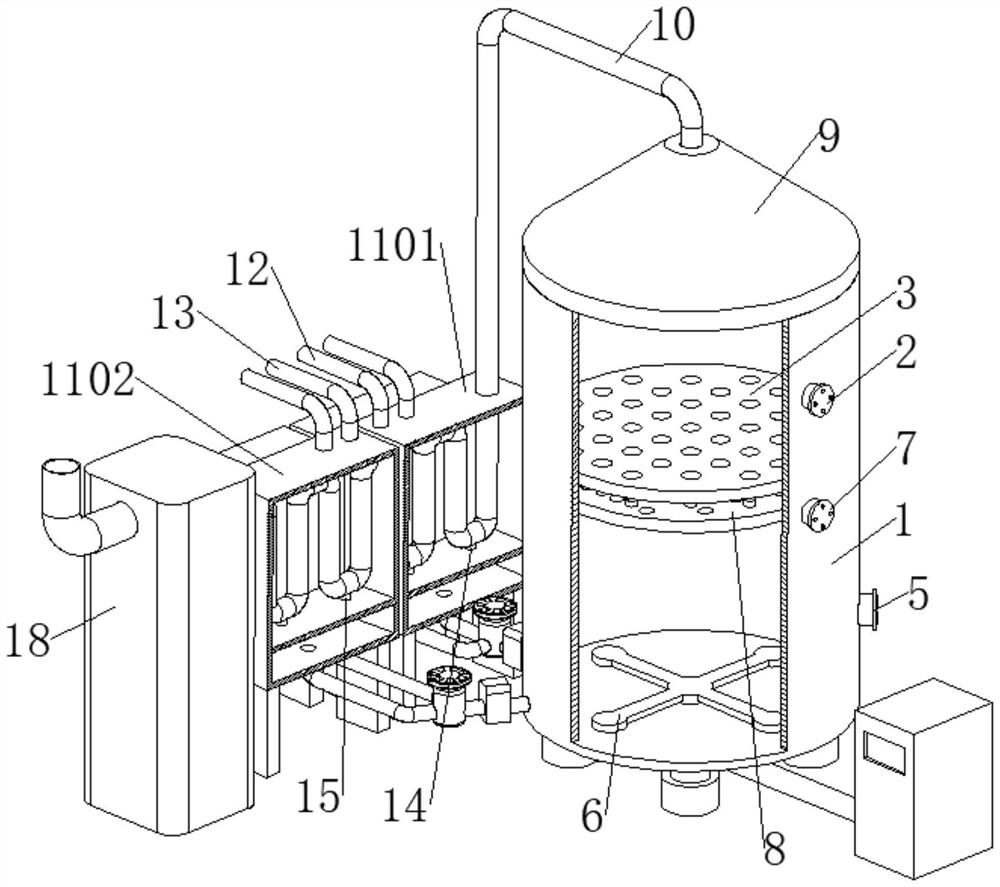

[0052] S1. Filling: through the filling pipe 2 installed on the outer end wall above the tank body 1, fill a plurality of collision-removing balls 4 on the barrier grid 3;

[0053] S2. Feeding: Inject the styrene solution containing the polymerization inhibitor into the bottom end of the tank body 1 through the feed pipe 5 installed on the outer end wall below the tank body 1;

[0054] S3, TBC removal: the liquid-phase styrene containing TBC passes through the Al2O3 filler layer, TBC is adsorbed on the surface of the filler, and styrene is purified;

[0055] S4, regeneration: 1) adsorption: after running for a period of time, the Al2O3 filler is gradually saturated, and the purification effect of styrene becomes poor, so it needs to be regenerated. At this time, the styrene in the absorption tower needs to be emptied;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com