Suction combined type solidification spraying device

A spray device, combined technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

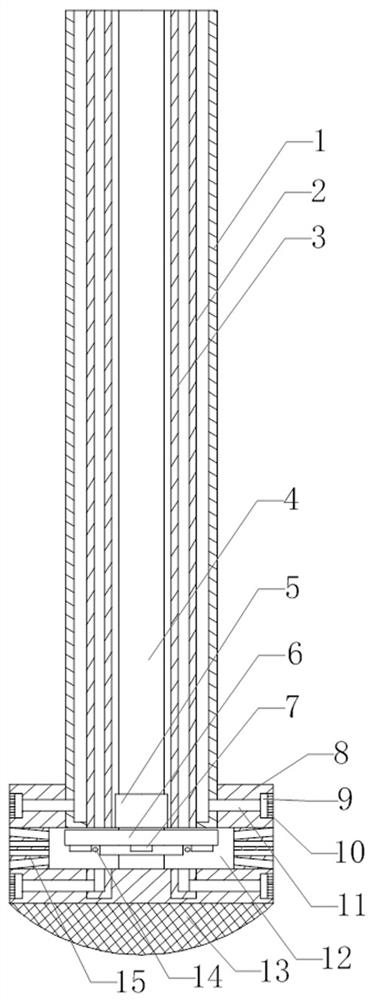

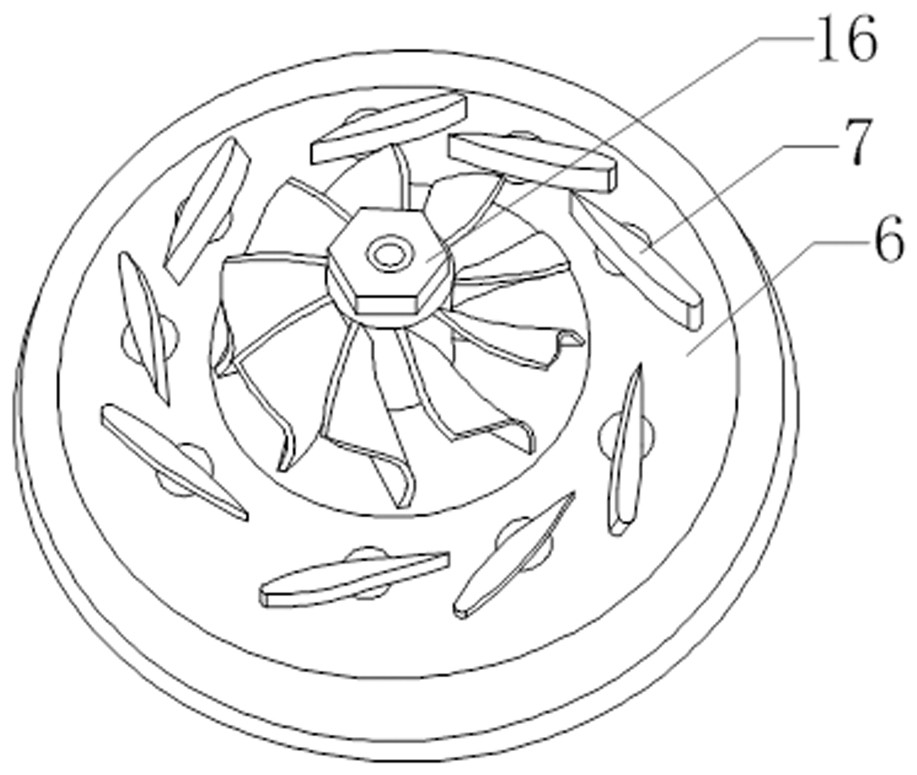

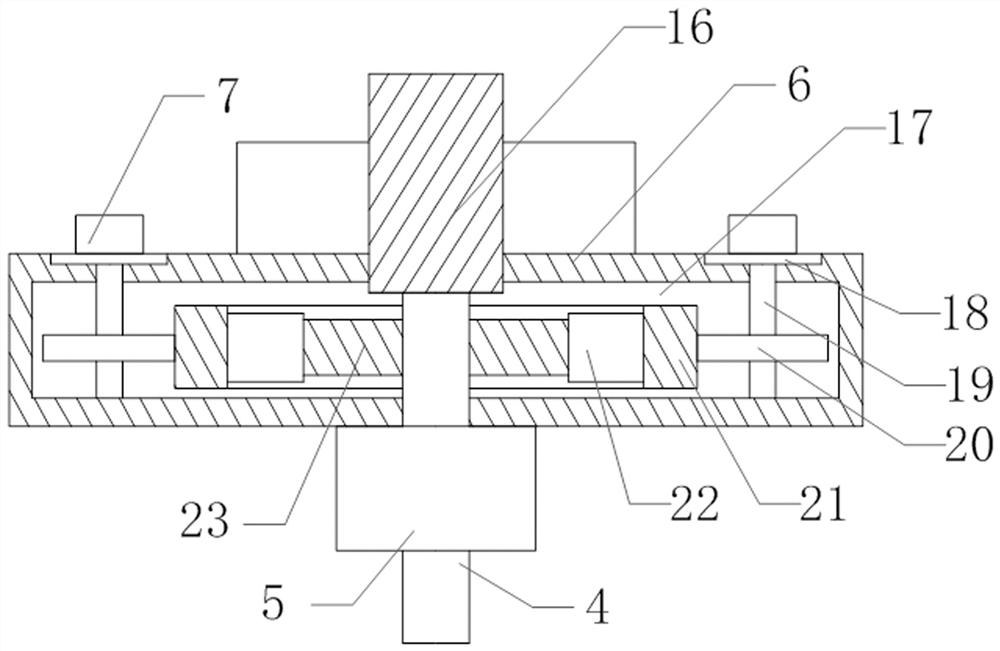

[0032] Such as Figures 1 to 5 As shown, the present embodiment includes a cylindrical spray nozzle 8, the middle part of the spray nozzle 8 is provided with a rotary spray chamber 12, and the upper end surface of the spray nozzle 8 is provided with an outer casing 1 communicating with the rotary spray chamber 12. There is a rotating shaft 4 inside, and a disc 6 is arranged in the rotary spray chamber 12. The lower end of the rotating shaft 4 moves through the middle of the disc 6 and then extends downward, and a turbine 16 is arranged on the extension of the rotating shaft 4. Along the spray head 8 A plurality of jet orifice groups 15 communicating with the inside of the swirl spray chamber 12 are arranged at intervals on its outer peripheral wall in the circumferential direction, and a plurality of deflectors 7 are rotated on the lower surface of the disc 6, and a plurality of deflectors 7 Distributed around the turbine 16 in an annular array, an adjustment cavity 17 is open...

Embodiment 2

[0037] Such as Figures 1 to 5 As shown, this embodiment also includes an inner sleeve 3 coaxial with the outer sleeve 1, and a cylinder 2 is also provided between the outer sleeve 1 and the inner sleeve 3, and between the outer sleeve 1 and the cylinder 2 , An annular space is formed between the cylinder body 2 and the inner casing 3, and an annular baffle is arranged at the lower end of the outer casing 1, and the annular baffle seals the bottom of the annular space between the outer casing 1 and the cylinder 2, so The lower end of the cylinder 2 is provided with an annular baffle, which seals the bottom of the annular space between the inner sleeve 3 and the cylinder 2, and a plurality of shunt pipes 24 are arranged on the lower surface of the annular baffle to divert the flow. The pipe 24 communicates with the annular space between the inner casing 3 and the cylinder body 2, and a plurality of distribution pipes 24 are placed in the wall of the nozzle 8, and a plurality of...

Embodiment 3

[0042] Such as Figures 1 to 5As shown, this embodiment is on the basis of Embodiment 1. The nozzle includes a guide tube 11, a buffer chamber 9, and a plurality of air holes 10 communicating with the buffer chamber 9. The buffer chamber 9 is set in the wall of the nozzle 8, and a plurality of The air holes 10 are provided on the outer peripheral wall of the nozzle 8, one end of the guide tube 11 communicates with the buffer chamber 9, the other end of the guide tube 11 communicates with the shunt tube 24, the annular space between the outer sleeve 1 and the cylinder body 2 connected. The two groups of nozzles realize the pumping function of the fluid respectively, and the two groups of spray groups are respectively located above and below the jet hole group 15; Flow into the buffer chamber 9, and then evenly disperse to the wall of the pile hole 28 through the multi-channel air holes 10, and when the suction is performed, the mixed liquid of the cleaning liquid and the mud i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com