Wood grinding device

A grinding and board technology, which is applied in the direction of grinding/polishing safety device, grinding feed movement, grinding workpiece support, etc., can solve the problems of motor burning, loss, motor load increase, etc., to achieve changing firmness, The effect of maintaining precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The specific embodiments of the present invention will be further described below;

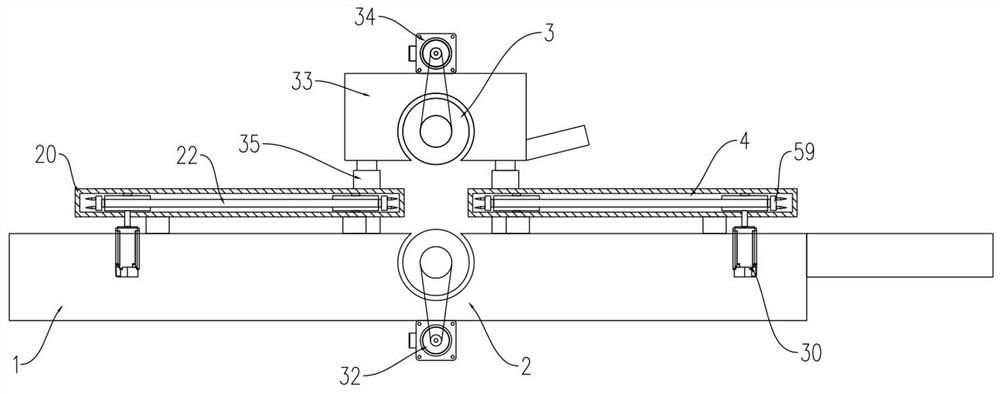

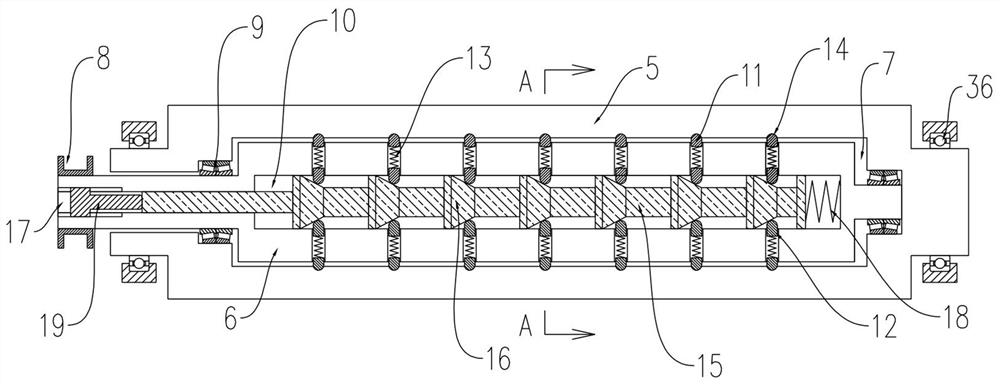

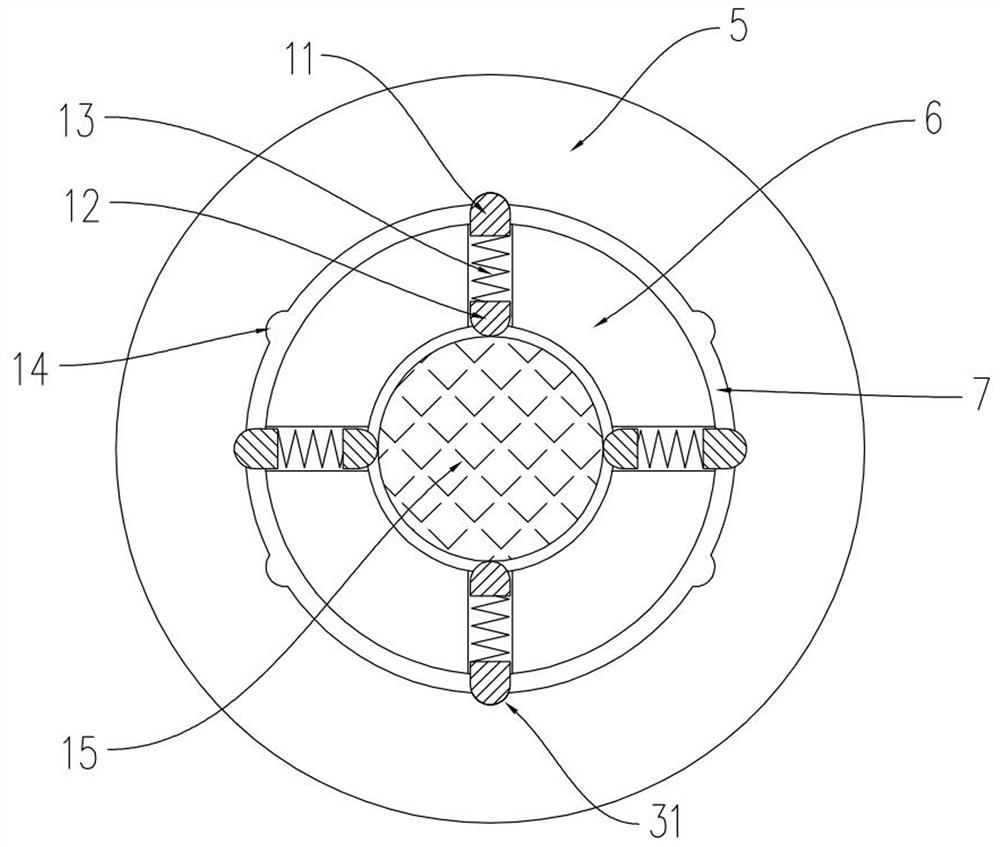

[0041] See figure 1 One wood-grinding apparatus of the present invention, the two-sided grinding and wood chips are integrated, and the wooden board is fixed and transmitted and transmitted, and when moving to the lower grinding mechanism 2 and the upper grinding mechanism 3, The machining treatment is simultaneously processed on both sides of the upper and lower sides of the wooden board. The work efficiency includes the grinding platform 1, and the grinding platform 1 is provided with a lower grinding mechanism 2 and an upper grinding mechanism 3, and the lower grinding mechanism 2 is disposed on mill. The upper surface of the platform 1 is provided on the upper side of the lower grinding mechanism 2, when the board moves into the board, the lower grinding mechanism 2 and the upper grinding mechanism 3 simultaneously grinds the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com