Nanofiber composite fabric and production method thereof

A technology of nanofibers and production methods, applied in the fields of fiber processing, chemical characteristics of fibers, chemical instruments and methods, etc., can solve the problems of inability to discharge liquid water, unsuitable for wearing, and feel wet and cold, and achieve stable and controllable process conditions. Improved wearing comfort and improved heat retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention provides a nanofiber composite fabric and a production method thereof. The nanofiber composite fabric can meet the wearing comfort requirements of daily outdoor sports, and can discharge liquid sweat and water vapor generated by human body movements, and at the same time can play a role of windproof The function of keeping warm and breathable, the production method is simple, the process conditions are stable and controllable, and continuous production can be carried out.

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings.

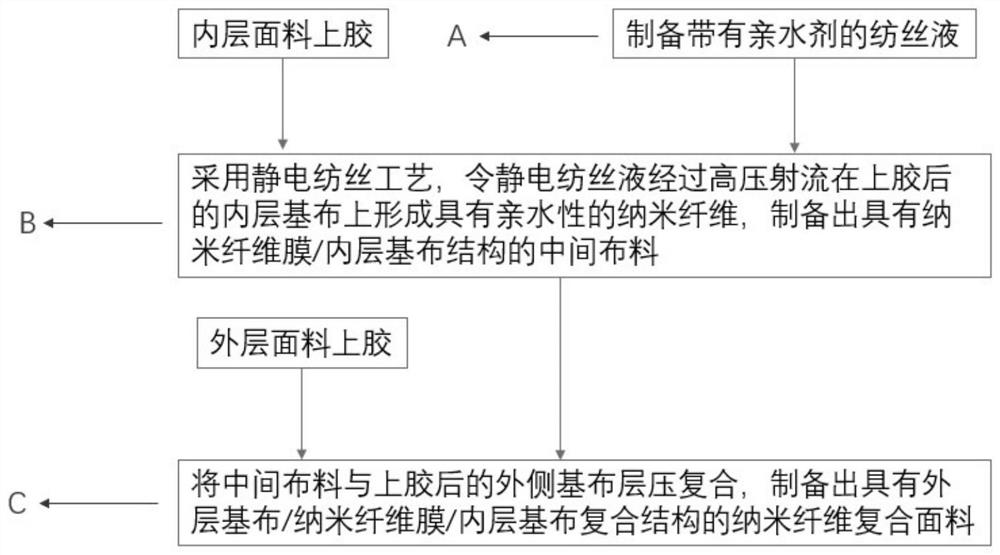

[0030] The invention firstly provides a production method of nanofiber composite fabric. figure 1 It is a flow chart of the production method of the nanofiber composite fabric according to the embodiment of the present invention. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com