Method for efficiently separating arsenic and antimony in high-arsenic smoke dust

An arsenic fume and high-efficiency technology is applied in the fields of non-ferrous metallurgy environmental protection and comprehensive resource recycling, achieving the effects of good application prospects, simple operation, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

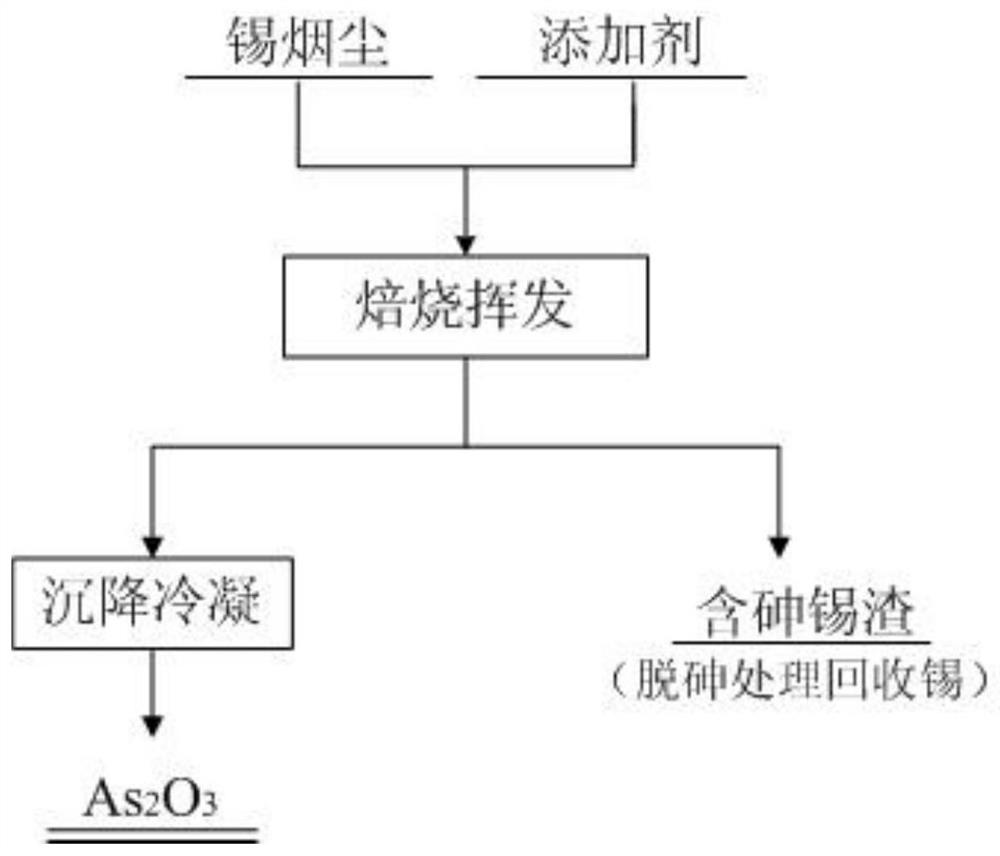

[0016] A method for efficient separation of arsenic and antimony in high-arsenic dust, such as figure 1 As shown, the method steps are as follows:

[0017] (1) Antimony fixation: mix 10kg of high-arsenic dust (arsenic content is 63.76%, antimony content is 0.776%) with 3kg industrial grade MnO 2 (MnO 2 The content is 70wt.%) and mixed evenly, placed in a muffle furnace for roasting, the roasting temperature is 380 ° C, and the reaction is 3h. During this process, As 2 o 3 Into the flue gas, use bag dust to collect As 2 o 3 The flue gas is collected to obtain As 2 o 3 Products (As 2 o 3 content ≥ 99%), after the reaction, arsenic-containing and antimony-rich roasted slag (also called arsenic-removed slag) is obtained. Antimony is enriched in the slag, realizing the effective separation of arsenic and antimony.

[0018] (2) Volatile arsenic: The arsenic-containing and antimony-rich roasted slag was heated up to 650°C in the muffle furnace for 6 hours. During this proce...

Embodiment 2

[0021] A method for efficiently separating arsenic and antimony in high-arsenic dust, the method steps are as follows:

[0022] (1) Antimony fixation: mix 10kg of high-arsenic dust (arsenic content is 69.73%, antimony content is 0.36%) with 3kg industrial grade MnO 2 , 1kg copper oxide (MnO 2 The content is 30wt.%) and mixed evenly, placed in a muffle furnace for roasting, the roasting temperature is 500 ° C, and the reaction is 2h. During this process, As 2 o 3 Flue gas is collected to obtain As 2 o 3 Products (As 2 o 3 content ≥ 99%), after the reaction is completed, arsenic-containing and antimony-rich roasted slag is obtained.

[0023] (2) Volatile arsenic: Continue to heat up the arsenic-containing antimony-rich roasted slag to 750°C for 3 hours. During this process, the volatilized As 2 o 3 The flue gas is collected, and As is obtained after the reaction 2 o 3 Products (As 2 o 3 content ≥ 99%) and secondary materials containing antimony.

[0024] It can be s...

Embodiment 3

[0026] A method for efficiently separating arsenic and antimony in high-arsenic dust, the method steps are as follows:

[0027] (1) Antimony fixation: mix 10kg of high-arsenic dust (arsenic content is 31.69%, antimony content is 1.68%) with 1kg industrial grade MnO 2 , 0.5kg of potassium permanganate, 0.5kg of hydrogen peroxide (MnO 2 The content is 30wt.%) and mixed evenly, placed in a muffle furnace for roasting, the roasting temperature is 300 ° C for 6h, in the process of As 2 o 3 Flue gas is collected to obtain As 2 o 3 Products (As 2 o 3 Content ≥ 99%), after the reaction is completed, arsenic-containing and antimony-rich roasted slag is obtained.

[0028] (2) Volatile arsenic: The obtained arsenic-containing and antimony-rich roasted slag was heated up to 500°C for 4 hours. During this process, the volatilized As 2 o 3 The flue gas is collected, and As is obtained after the reaction 2 o 3 Products (As 2 o 3 content ≥ 99%) and secondary materials containing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com