Assembly type steel structure for civil engineering

A civil engineering and prefabricated technology, applied in the direction of building structure, construction, etc., can solve the problems affecting the stability of the structure and the reduction of connection strength, and achieve the effect of increasing the stability of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

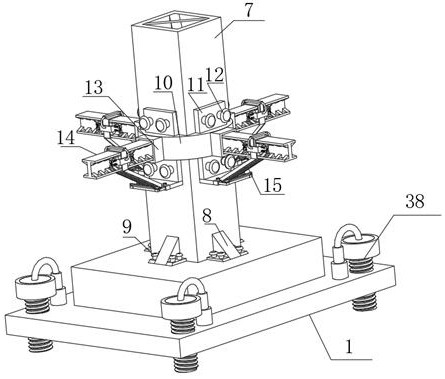

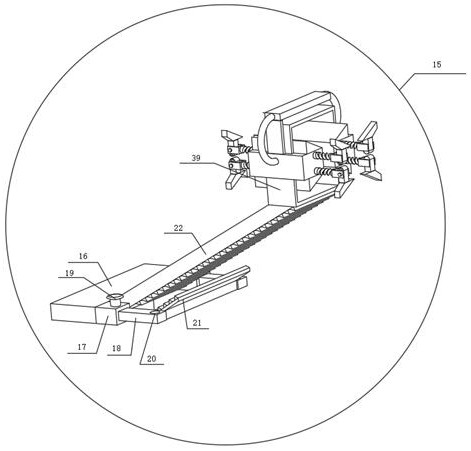

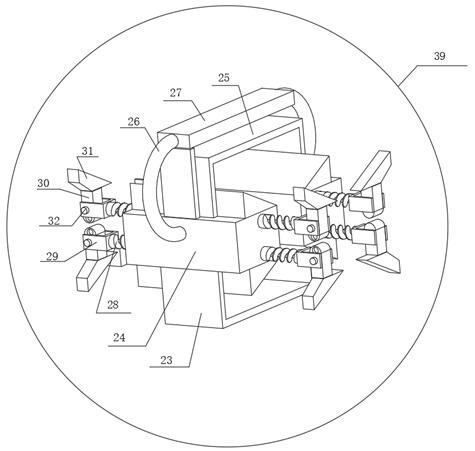

[0026] see Figure 1-Figure 5 , the present invention provides the following technical solutions: an assembled steel structure for civil engineering, including a base 1, four sets of through holes are arranged at the upper and lower ends of the base 1, and protective ground inserting parts are provided in the four sets of through holes 38. The four sets of protective ground inserting parts 38 all include the ground anchor rod 2 and the linkage telescopic column 3. The linkage telescopic column 3 is composed of a fixed column and a telescopic column. The top of the fixed column is provided with an opening, and the telescopic column is located at the top opening of the fixed column. Inside, the telescopic column can extend into the inner cavity of the fixed column, and the top of the linkage telescopic column 3 is provided with a U-shaped connecting pipe 4, and one end of the U-shaped connecting pipe 4 not connected to the linkage telescopic column 3 is provided with a rubber cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com