Reinforced concrete partition wall connection node structure

A technology for reinforced concrete and connecting nodes, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of making baffles take a long time, reduce work efficiency, occupy construction time, etc., to shorten the construction period, improve efficiency and strength. enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

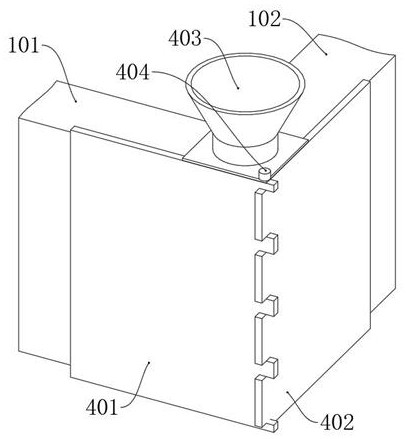

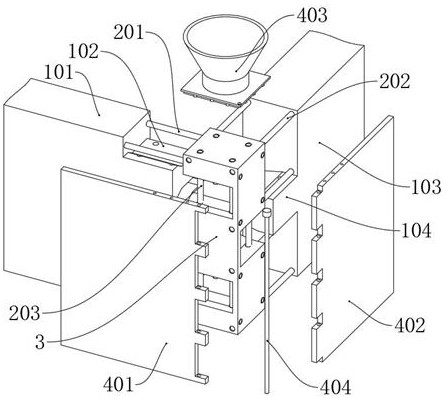

[0037] Example: Please refer to Figure 1 to Figure 11 :

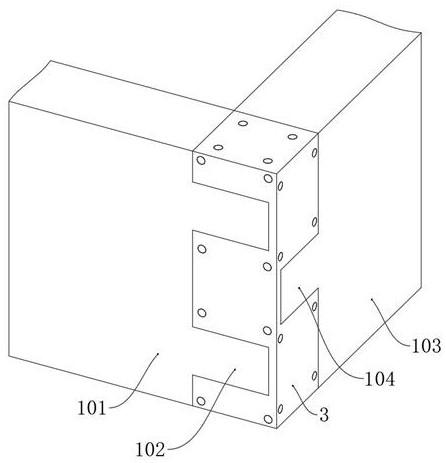

[0038] The present invention proposes a reinforced concrete partition wall connection node structure, comprising: a reinforcement group 2; a wall 1 is poured outside the reinforcement group 2, and a transverse wall 101 of the wall 1 is poured outside the transverse reinforcement 201 of the reinforcement group 2; The intersection of the longitudinal wall 103 and the transverse wall 101 of the wall 1 is poured with concrete blocks 3;

[0039] In addition, according to an embodiment of the present invention, as figure 2 , Figure 5 , Figure 6 As shown, the wall 1 also includes: a fixed block A102; the fixed block A102 is a trapezoidal structure, and two fixed blocks A102 are connected to the right side of the horizontal wall 101; the fixed block A102 cooperates with the fixed block B104 to assist the concrete block 3 fixed to prevent the concrete block 3 from being shaken away from the wall 1 when it is not complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com