In-depth type funnel grouting sleeve grout supplementing method

A grouting sleeve and grouting technology, which is applied to cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as holes in the sleeve, and achieve the effect of accelerating the flow speed and improving the cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

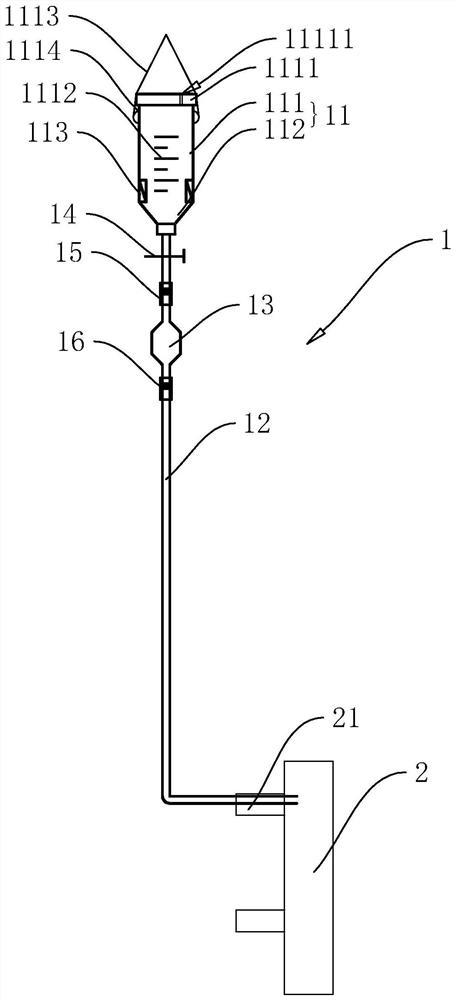

[0039] The following is attached figure 1 The application is described in further detail.

[0040] The embodiment of the present application discloses a grouting method for a deep funnel grouting sleeve. refer to figure 1 , a deep funnel grouting sleeve grouting method, including the following steps:

[0041] S1. Preparation of grouting material: Before grouting construction, prepare grouting material, including cement 30%, mineral admixture 12%, fine aggregate 35%, functional material 1.8%, composite admixture 4.2 %, mixing water 17%. Wherein, the cement is PO52.5 ordinary Portland cement, and in the mineral admixture, there are 55% of fly ash, 25% of glass microspheres, and 20% of silica fume, and the silica fume is SF90 grade. Among the functional materials, there are 5% nano-calcium carbonate, 15% nano-alumina, 55% sodium sulfate, 3% dihydrate gypsum, 12% sodium humate, 6% talcum powder, and 4% sodium lauryl sulfate. Among the admixtures, polycarboxylate superplastici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com