Sludge separation device

A separation device and sludge technology, applied in separation methods, filtration separation, sludge treatment and other directions, can solve the problems of inability to separate sludge, sludge impurities and sewage, waste of filtration time, etc., so as to save separation time and avoid pollution. Mixing materials to ensure the effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

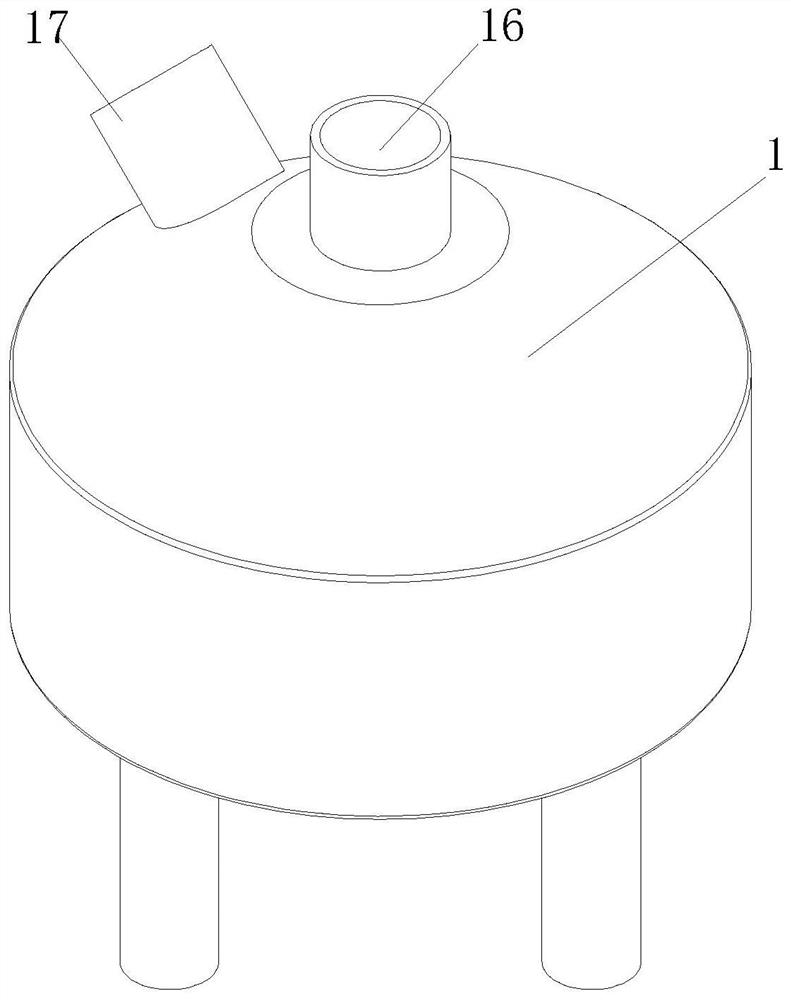

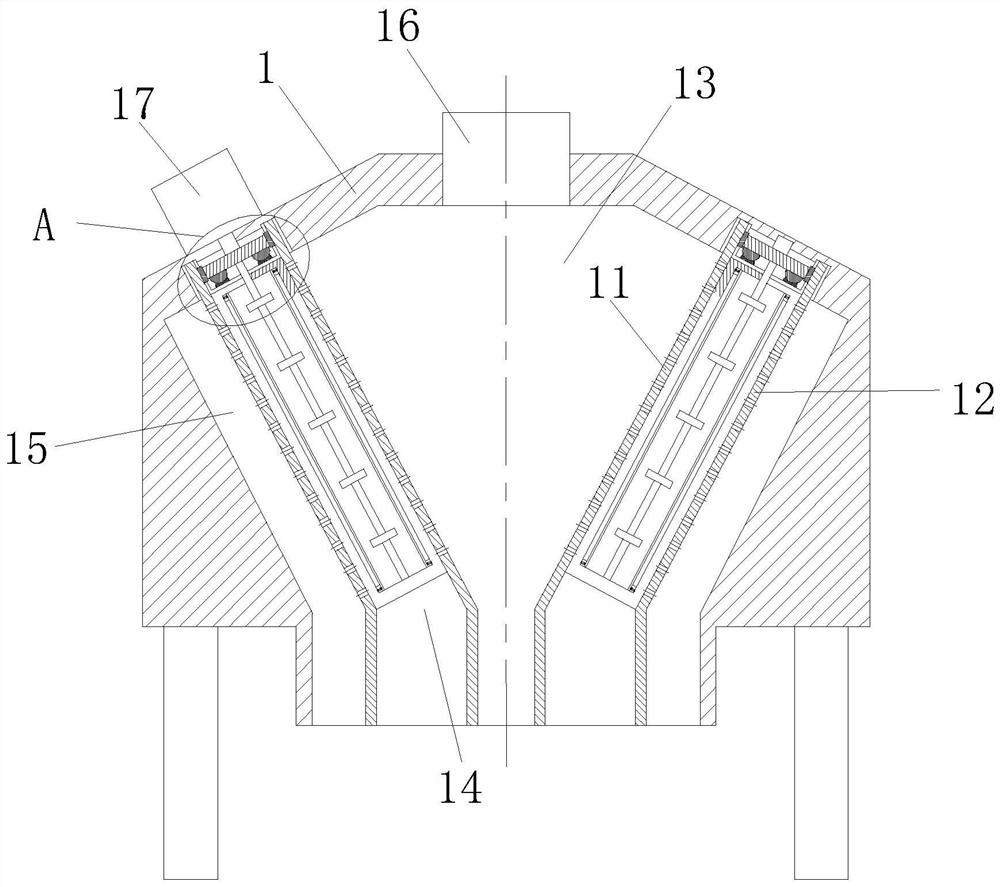

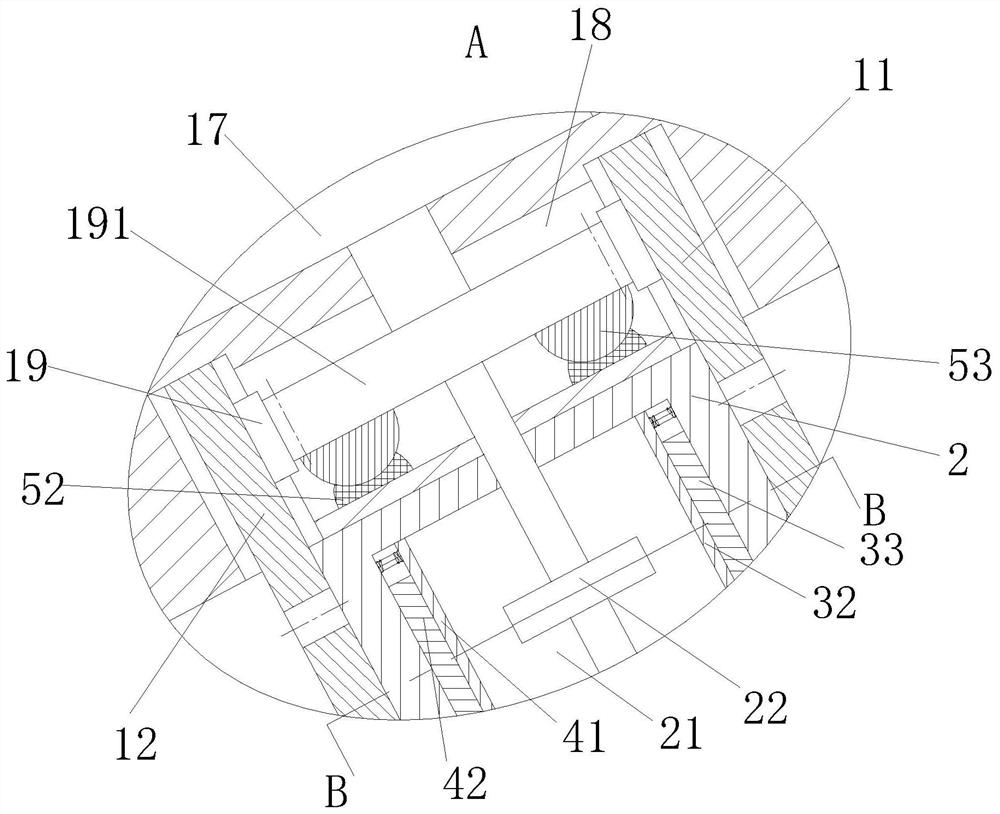

[0030] Such as Figure 1 to Figure 5 As shown, a sludge separation device according to the present invention includes a separation box 1; a feed inlet 16 is provided at the center of the top of the separation box 1; a first annular groove is provided on the inner wall of the slope at the top of the separation box 1 And the second annular groove, and the first annular groove is close to the center line of the separation box 1; the first filter plate 11 is rotatably connected in the first annular groove; the second filter plate 12 is rotatably connected in the second annular groove; The cross-section of the first filter plate 11 and the second filter plate 12 is an inverted cone; the inner diameter of the filter hole of the second filter plate 12 is less than the inner diameter of the filter hole of the first filter plate 11; the first filter plate 11 and A miscellaneous chamber 13 is formed at the center of the separation box 1, and the feed port 16 and the miscellaneous chambe...

Embodiment 2

[0040] see Image 6 As shown in Comparative Example 1, as another embodiment of the present invention, a third annular groove 7 is provided on the outer wall of the cam 22; a set of cutting blades 71 is fixedly attached to the bottom of the third annular groove 7, And the cutting piece 71 is triangular; when working, because after the moisture in the sludge decreases, the viscosity of the sludge increases, which will affect the rotation of the cam 22 in the mud discharge chamber 14, and then affect the energy consumption of the motor 17, so A cutting piece 71 is arranged inside the cam 22. The cutting piece 71 can not only reduce the influence of the external sludge on the rotation of the cam 22, but also pulverize some solid particles in the sludge, and prevent the sludge from solidifying, which affects the quality of the sludge. Discharge.

[0041] Working principle: Put the municipal sludge into the separation box 1 through the feed port 16. At this time, the outlets of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com