Double-loop power transmission line cable terminal pole

A cable termination and transmission line technology, applied in cable termination, cable space arrangement/configuration, building type, etc., can solve the problems of expanding the uneven settlement of the tower pile foundation, large area, increasing the tower load, etc. The risk of cross-overlap, the convenience of construction and maintenance operations, and the effect of ensuring vertical verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

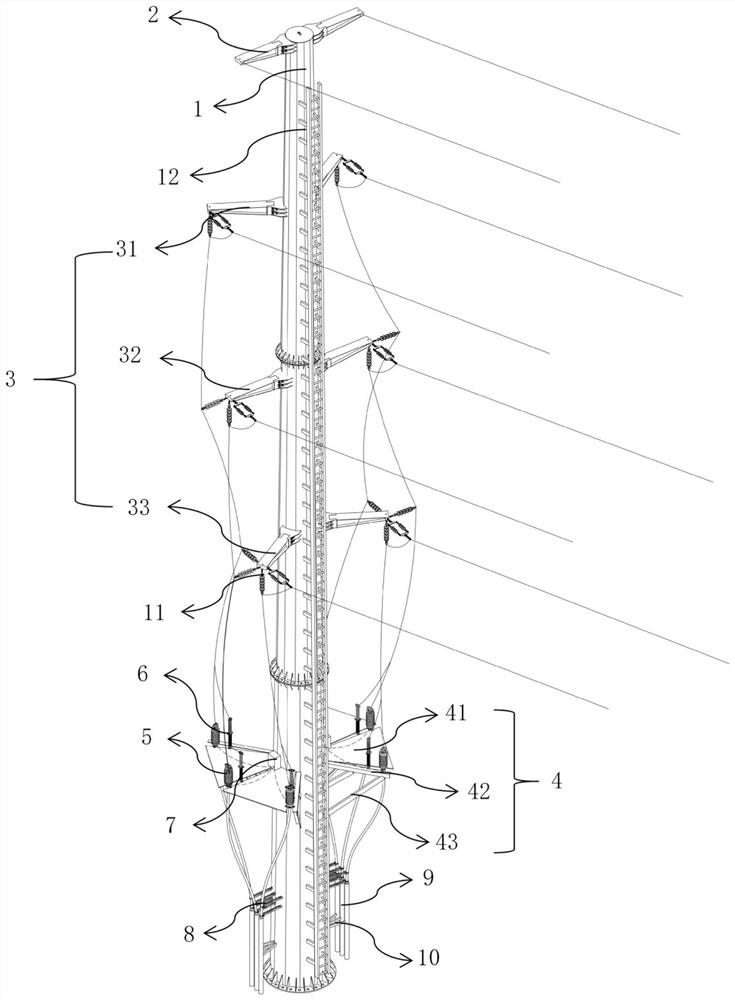

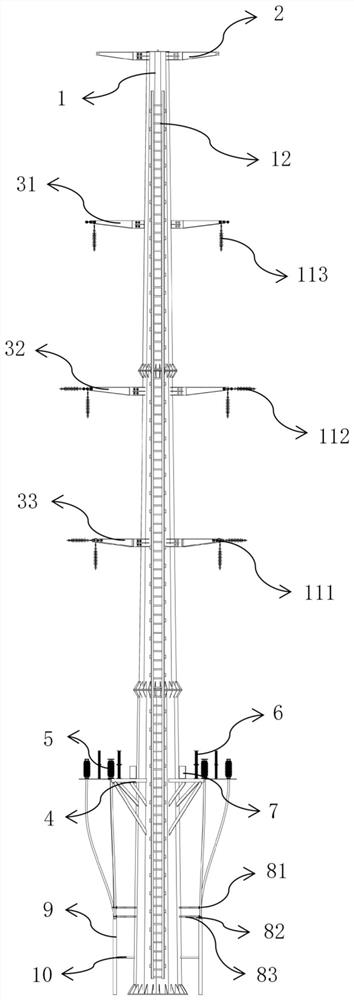

[0025] Such as figure 1 and figure 2 As shown, a double-circuit transmission line cable terminal rod includes a rod body 1 , a ground wire cross arm 2 , a transfer cross arm 3 , a comprehensive platform 4 and a ladder 12 . The rod body 1 is a three-section bolt spliced steel rod structure with different diameters. The axis of the rod body 1 is perpendicular to the ground, and the diameter of the cross-section of the rod body 1 gradually increases from top to bottom; at least one pair of ground wire cross arms 2 are fixed on the rod body 1. The top is perpendicular to the rod body 1, and the horizontal angle between a pair of ground wire cross arms 2 is 180 degrees. In the direction of the ground projection, the axis is perpendicular to the connecting horizontal overhead wire.

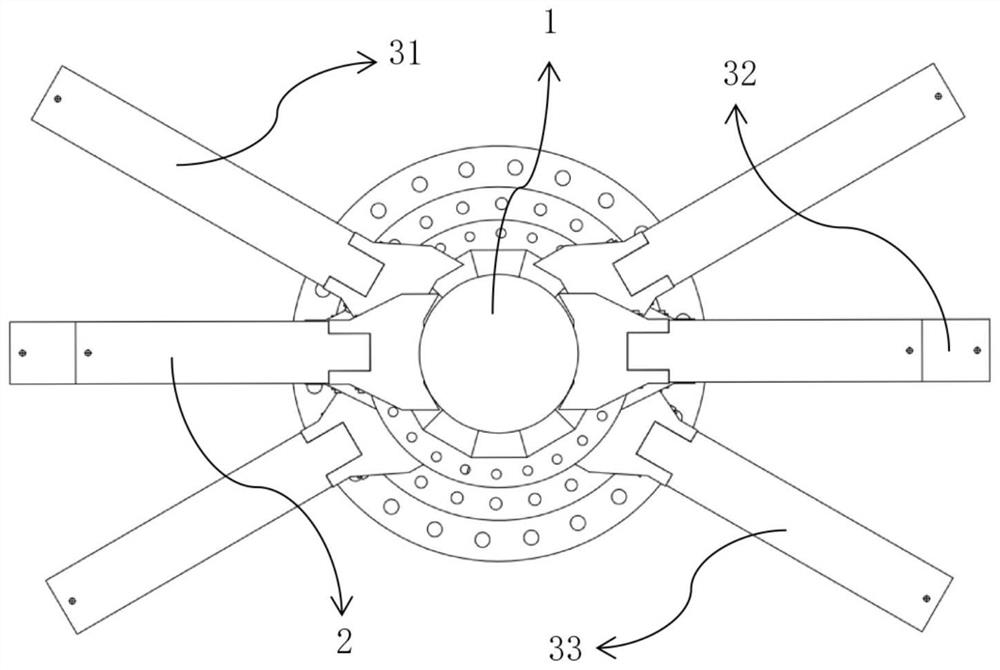

[0026] Such as image 3 As shown, the specifications and dimensions of the transfer cross-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com