A kind of extremely broken surrounding rock roadway through the ruins and excavation technology

An extremely broken and roadway technology, which is applied in the field of extremely broken surrounding rock roadway piercing and excavation technology, can solve the problems of great difficulty, danger, quicksand-like falling, etc., to avoid quicksand-like falling, increase stability, reduce The effect of construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

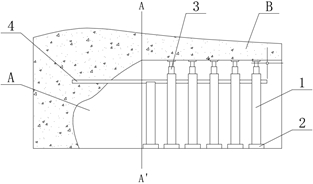

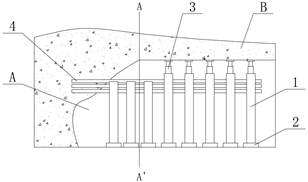

[0037] see Figure 1-5 , the present invention provides a technical solution;

[0038] An extremely broken surrounding rock roadway tunneling and excavation technology, the technology includes a safe and simple construction module

[0039] The safe and simple construction module is used to reduce the difficulty and danger of construction in the caving area. The construction steps include pre-supported steel structure support frame module, advanced construction drill pipe body module, steel frame body reinforcement support module, drill pipe body reinforcement support Modules and roadway side reinforcement support modules.

[0040] The pre-supported steel structure supporting frame is the first step. A number of steel frame bodies are pre-supported on the side facing away from the face outside the caving area to obtain a pre-supported supporting frame 1. In the pre-supported supporting frame 1, The height of the support frame 1 on the side closest to the face is lower than th...

Embodiment 2

[0047] see Figure 1-5 , the present invention provides a kind of technical scheme,

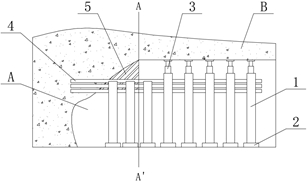

[0048] An extremely broken surrounding rock roadway tunneling and excavation technology, the technology includes a construction module for preventing quicksand falling out, and during construction, the construction module for preventing quicksand falling out is used to prevent quicksand-like caving during construction of a roadway in a section of extremely broken surrounding rock. The construction process includes the backfill module of the roof and the material of the upper part and the knocking and asking of the roof module.

[0049] The backfilling of the top plate and the help material is the first step. After the fifth step is completed, the space between the three-layer drill pipe body 4 and the drill pipe body on the side of the support frame 1 are filled with fillers such as log, bamboo backboard or bagged perlite. 4. Fill the gap between 4 and the side of the roadway to prevent the ...

Embodiment 3

[0053] see Figure 1-5 , the present invention provides a kind of technical scheme,

[0054] An extremely fragmented surrounding rock roadway tunneling and excavation process includes a safe and simple construction module and a quicksand fall prevention construction module. During construction, the safe and simple construction module and the quicksand fall prevention construction module are carried out in sequence.

[0055] The safe and simple construction module is used to reduce the difficulty and danger of construction in the caving area. The support module and the roadway side reinforcement support module, the quicksand-fall prevention construction module is used to prevent the quicksand-like falling phenomenon during the roadway excavation construction in the extremely broken surrounding rock section, and the construction process includes the roof and side material backfilling module And knocking help ask the top module.

[0056] The pre-supported steel structure suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com