Switch type primary vertical shock absorber for high-speed train

A high-speed train, switch-type technology, applied in shock absorbers, spring/shock absorber design features, shock absorbers, etc., can solve problems such as damage to parts, and achieve the effect of improving the effect of vibration reduction and ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

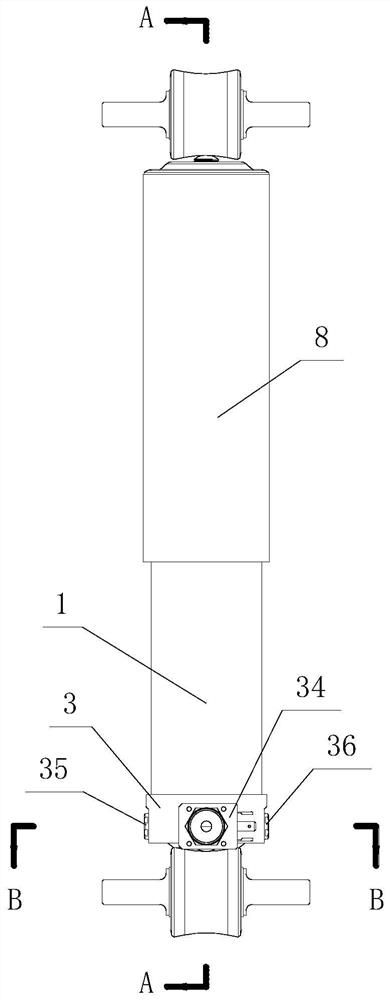

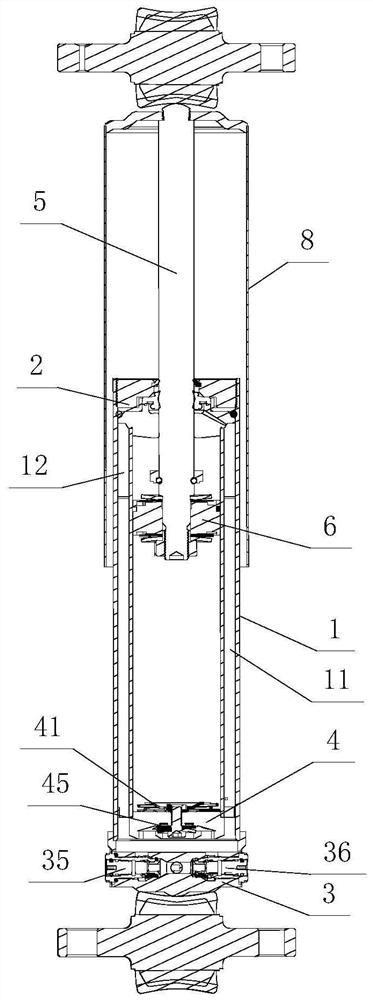

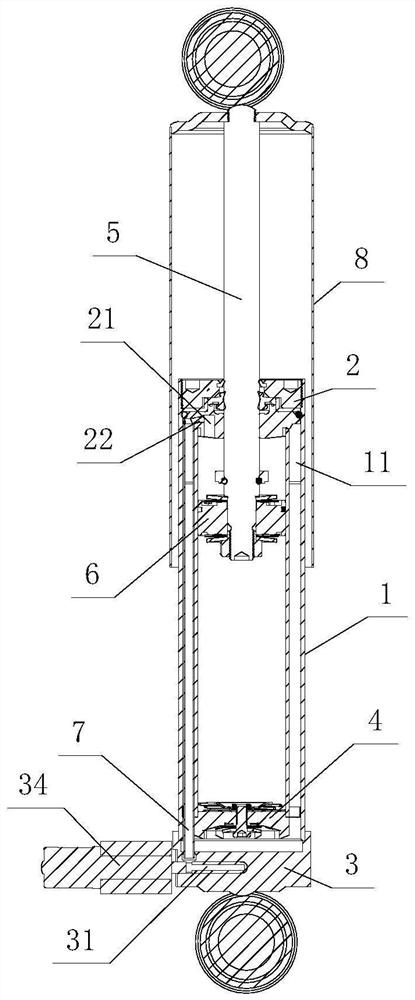

[0028] Such as Figure 1 to Figure 8 As shown, the switch-type primary vertical shock absorber for high-speed trains provided in this embodiment includes a cylinder body 1, a guide cover 2, a valve seat 3, a piston rod 5 and a piston assembly 6, and the top and bottom of the cylinder body 1 are respectively A guide cover 2 and a valve seat 3 are provided, and the guide cover 2 and the valve seat 3 seal the two ends of the cylinder body 1, and are used to fill the cylinder body 1 with oil, and the cylinder body 1 is processed with a hollow oil storage Cavity 11, the top of the oil storage chamber 11 is provided with a compressible air bag 12, the bottom of the oil storage chamber 11 is equipped with a bottom valve 4, and the bottom valve 4 is processed with an oil return hole 46 and an oil return hole connecting the cylinder 1 and the oil storage chamber 11. hole 46, the side of the bottom valve 4 near the guide cover 2 is provided with an oil return valve 41 that blocks the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com