Transportation pipeline vibration pick-up leakage detection method based on low-reflection chirp grating array

A chirped grating and low-reflection technology, applied in the field of pipeline leakage detection, can solve the problems of difficulty in implementation and monitoring accuracy, and achieve the effect of easy implementation, easy implementation, and improved judgment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

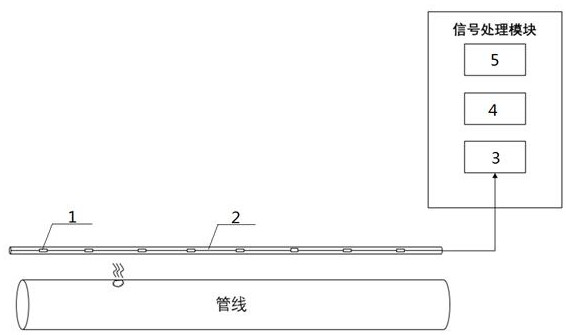

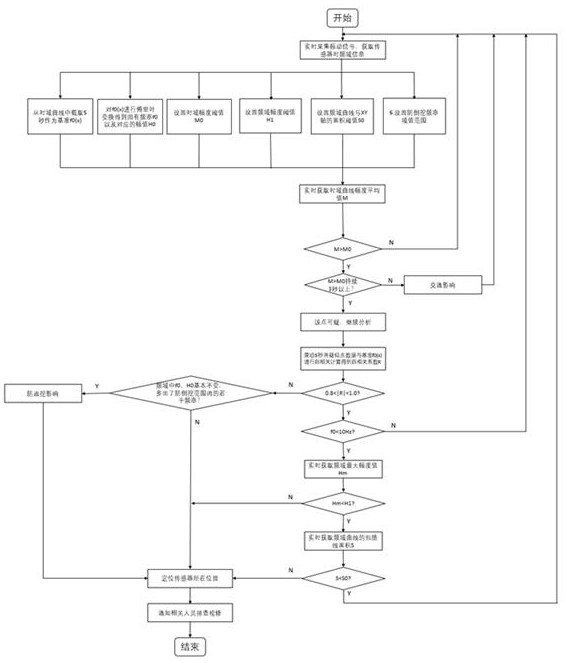

[0078] See figure 1 and figure 2 , A transmission conduit pick-up leak detection method based on a low reflection 啁 光 grating array, including the sensing fiber optic cable laying process, database setting process, signal analysis process;

[0079] The sensing fiber optic cable laying process includes: first set a plurality of vibration sensors 1 in the internal interval of the weak light gate array sensing cable 2, the vibration sensor 1 is made of a 啁啾 grating, and a weak grating array is transmitted. The optical cable 2 is paved over the tube of the pipe axis, and then signals the end of the weak light gate array sensing cable 2 to one end of the fiber grating demodulator 3, and the other end of the fiber grating demodulator 3. A terminal display 5 is connected to the computer 4 and a terminal display 5 is connected to the computer 4;

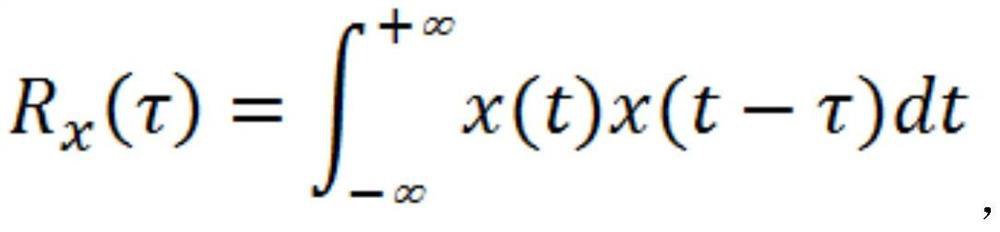

[0080] The database setting process includes: When the pipe has no leakage, when each vibration sensor 1 is acquired, the frequency domain info...

Embodiment 2

[0084] Basic content is the same as in Example 1. The difference is:

[0085] Preferably, M0 = (1.1-1.3) * mA, the H1 = (1.1-1.3) * H0, the S0 = (1.1-1.3) * SA. Further preferred M0 = 1.2 * mA, the H1 = 1.2 * H0, the S0 = 1.2 * SA.

Embodiment 3

[0087] Basic content is the same as in Example 1. The difference is:

[0088] It is preferred to have a predetermined period of 5 seconds, 10 seconds, 20 seconds, 30 seconds, 40 seconds, 60 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com