Detection method for judging treatment degree of fabric pretreatment procedure by dyeing method

A technology of processing degree and detection method, applied in the direction of color/spectral property measurement, measurement device, analysis material, etc., can solve the problem of determining the pre-processing process, etc., to achieve the effect of improving quality, good reproducibility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

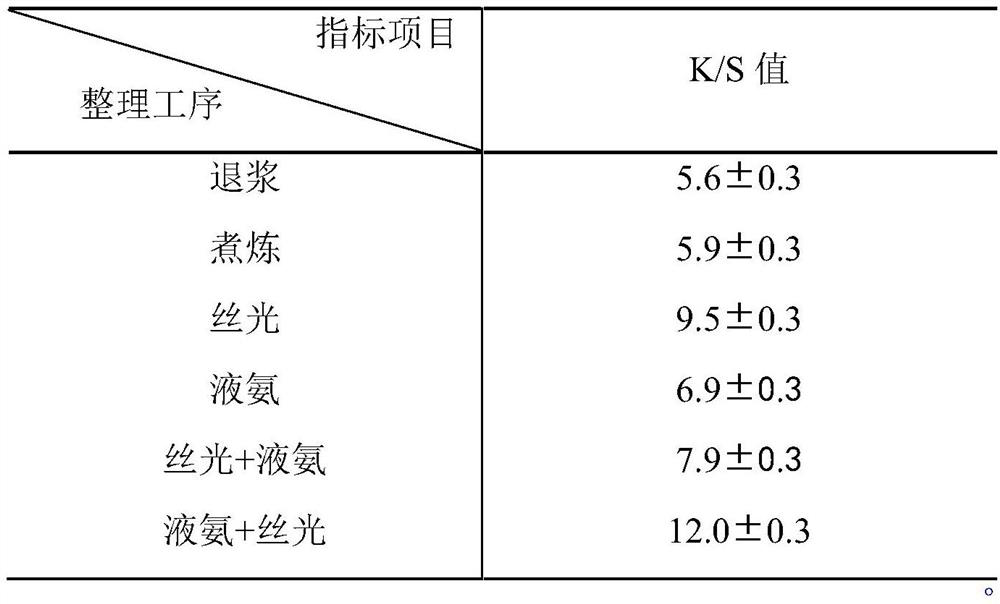

Embodiment 1

[0039] The sample is a white pure cotton plain fabric, using pure cotton 11.7tex yarn in the warp and weft directions, with a warp density of 137 threads / inch, a weft density of 78 threads / inch, and a gray fabric of 1,300 meters. The conventional pretreatment process of the fabric is desizing→scouring, Bleaching→mercerizing→liquid ammonia, leave half a meter of fabric for K / S value test in each process. Take another 50 meters of boiled and bleached fabric, do not mercerize, only do liquid ammonia, leave half a meter after the liquid ammonia, and process the rest for mercerizing, and test the K / S without processing mercerizing, only processing liquid ammonia, first liquid ammonia and then mercerizing value. in:

[0040] Desizing process: desizing enzyme DS-HT 8g / L, penetrant WAM 3g / L, refining agent SAU 2g / L, vehicle speed 65m / min, trough temperature about 50°C, steam at 100°C for 15 minutes, wash with water The tank temperature was set at 80°C, 90°C, 90°C, 80°C, and 70°C in ...

Embodiment 2

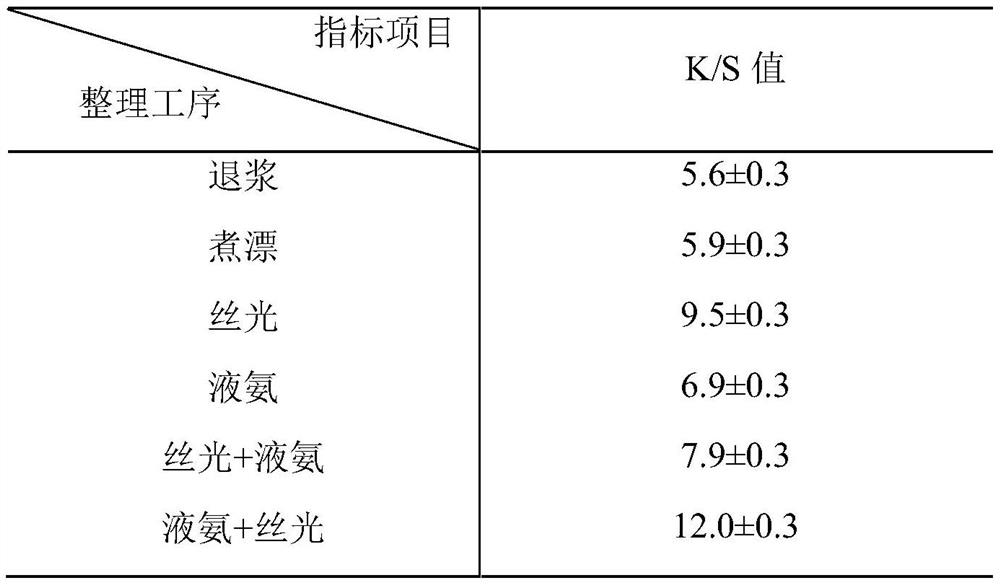

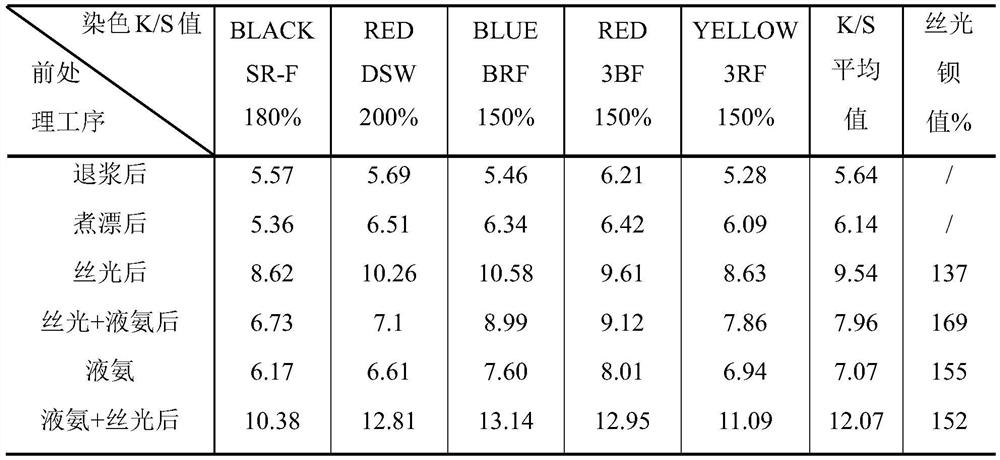

[0060] The sample is 5 pieces of white pure cotton satin fabric, the warp and weft directions are made of pure cotton 7.3tex plied yarn, the warp density is 127 threads / inch, the weft density is 83 threads / inch, the gray fabric is 4200 meters, the fabric is pre-treated and desized → boiled After scouring, bleaching, desizing, and boiling and bleaching, leave half a meter to test the K / S value.

[0061] Take 50 meters for mercerizing, leave half a meter for test after mercerizing, and test the K / S value of mercerizing without liquid ammonia, first mercerizing and then liquid ammonia respectively. Take another 50 meters to make liquid ammonia, leave half a meter after the liquid ammonia, and process the rest for mercerizing, test the K / S value of not processing mercerizing, only processing liquid ammonia, first liquid ammonia and then mercerizing. in:

[0062] Desizing process: desizing enzyme DS-L7g / L, penetrant WAM 2g / L, refining agent SAE2g / L, vehicle speed 63m / min, trough t...

Embodiment 3

[0081] The sample is a white pure cotton 3 / 3 positive and negative twill weave fabric, the warp and weft directions are made of pure cotton 14.6tex yarn, the warp density is 142 threads / inch, the weft density is 68 threads / inch, and the gray fabric is 2300 meters. Pulping → scouring, bleaching → mercerizing, because the fabric is easy to curl with liquid ammonia, only mercerizing is processed, and half a meter of fabric is reserved for K / S value testing in each process. in:

[0082] Desizing process: desizing enzyme DS-L 8g / L, penetrating agent WAM 3g / L, refining agent SAE 3g / L, vehicle speed 62m / min, trough temperature about 50°C, steam at 98°C for 18 minutes, wash the tank with water The temperature was set at 85°C, 90°C, 90°C, 80°C, and 70°C in sequence.

[0083] The scouring and bleaching adopts linkage, scouring process: 48Be° caustic soda 30g / L, penetrating agent WAM 3g / L, refining agent SAE 3g / L, wax remover WR-03 2g / L, vehicle speed 62 m / min, trough temperature Steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com