Flexible circuit board assembly, manufacturing method thereof and display device

A technology of flexible circuit boards and manufacturing methods, applied to printed circuit parts, circuits, printed circuits, etc., can solve the problems of MFPC without layout area and increased power consumption of OLED display modules, so as to reduce the risk of burnout and reduce line Wide, the effect that meets the layout requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

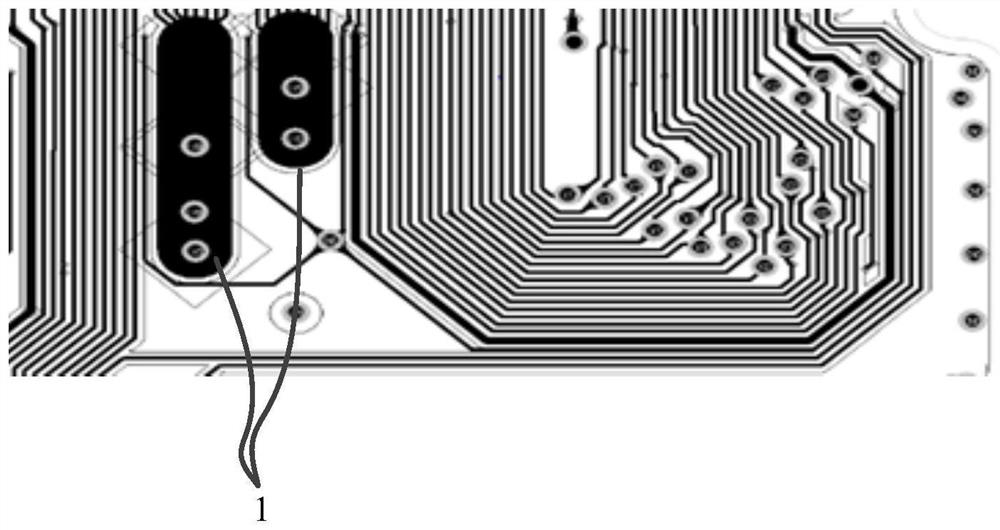

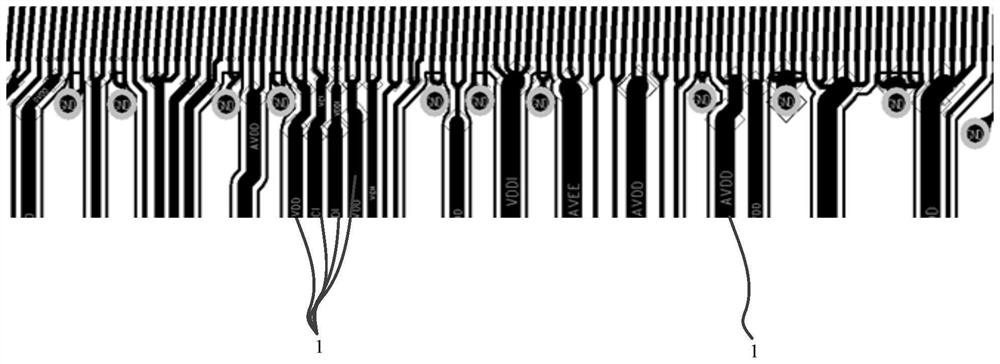

[0041] Such as figure 1 As shown, 1 is the power line. With the increase of the resolution of the display module, the driving current of the display module increases. In order to meet the resistance requirements of the power line 1, the line width of the power line 1 is larger, resulting in MFPC Dimensions are expanded. Additionally, if figure 2 As shown, when the MFPC is bound to the display module, due to insufficient space in the binding area, part of the width of the power line 1 needs to be sacrificed, resulting in a potential risk of burning the MFPC.

[0042] Embodiments of the present invention provide a flexible circuit board assembly, a manufacturing method thereof, and a display device, which can reduce the line width of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com