Heat dissipation device and manufacturing method thereof

A technology of heat dissipation device and manufacturing method, which is applied in the direction of cooling/ventilation/heating transformation, electrical equipment structural parts, electrical components, etc., and can solve the problems of insufficient heat dissipation, poor heat transfer effect in the top area of fins, and increased power consumption. major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

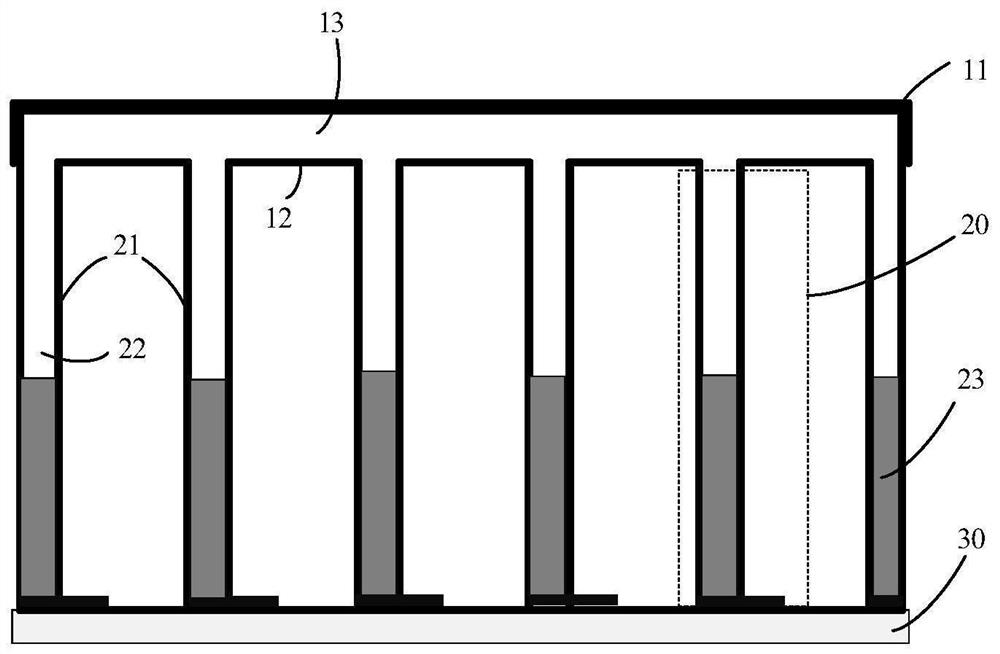

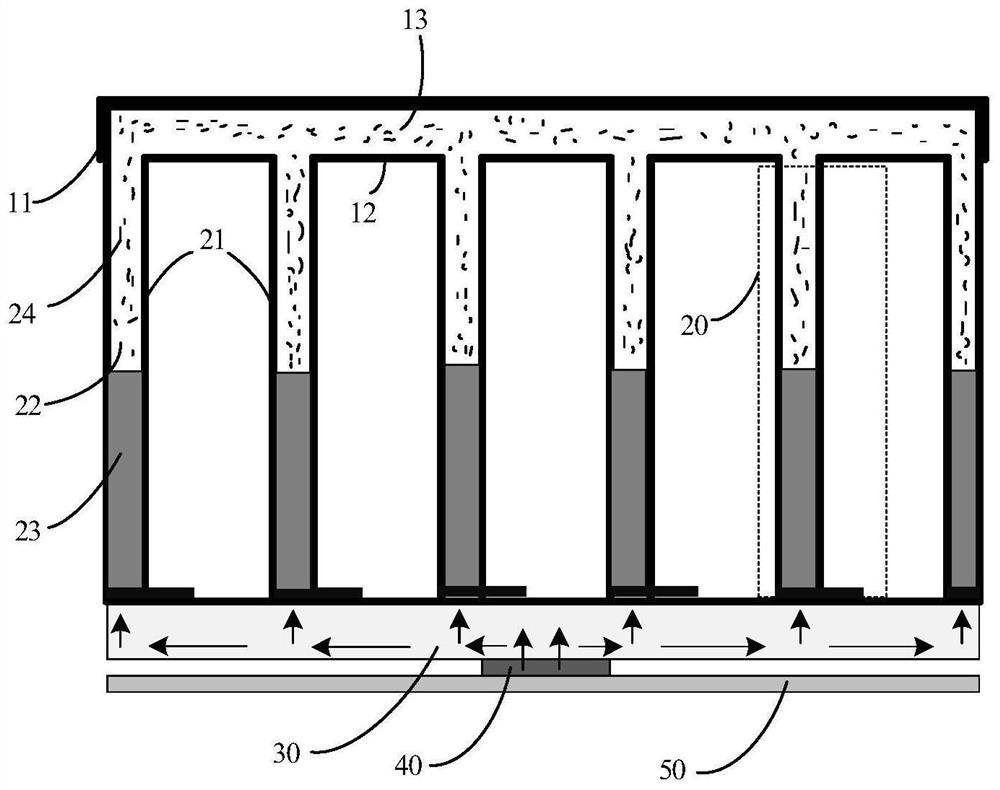

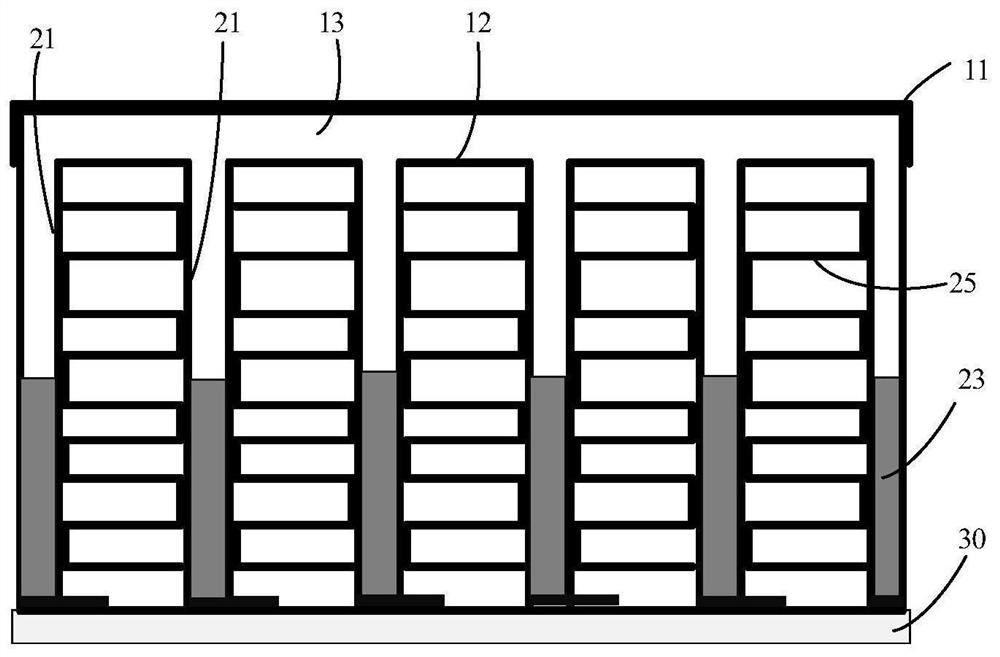

[0042] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

[0043] The traditional air-cooled radiator mainly rotates the fan to accelerate the air circulation, so as to dissipate the heat as soon as possible. If you want to improve its heat dissipation effect, you can achieve it in the following ways.

[0044] The first way is to increase the heat exchange capacity of the radiator by increasing the rotational speed of the fan, but this improvement is not significant, and may also cause heat generation problems of the radiator itself. In addition, it will also bring about a significant increase in noise. If it is installed in a relatively closed environment such as a car, the user experience will be poor.

[0045] The second way is to increase the thickness of the fins. After the thickness of the fins increases, the thermal resistance from the root to the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com