Two-component (2K) composition based on modified epoxy resins

A technology of epoxy resin and composition, which is applied in the direction of epoxy resin coating, mechanical equipment, coating, etc., and can solve problems such as hindering the proper development of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0150] In an exemplary embodiment of the invention, the two-component (2K) composition comprises:

[0151] (A) a first component comprising:

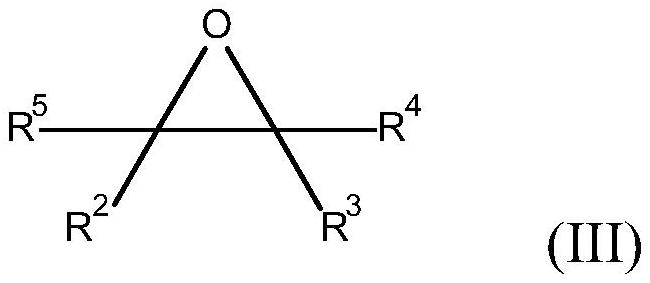

[0152] 10 to 60% by weight of a) at least one epoxy resin selected from the group consisting of glycidyl ethers of polyols and polyphenols; glycidyl esters of polycarboxylic acids; and epoxidized polyethylenically unsaturated hydrocarbons, esters , ethers and amides; and

[0153] 1 to 40% by weight of b) at least one elastomer-modified epoxy resin having an epoxy equivalent weight of 200 to 500 g / eq;

[0154] (B) a second component comprising:

[0155] c) a curing agent consisting of at least one compound having at least two epoxy-reactive groups per molecule, said curing agent being characterized in that it consists of 90 to 100 mole % of at least one alkoxy-containing Composed of an amino-functional silicone resin and 0 to 10% by weight of a second epoxy-reactive compound,

[0156] wherein the composition is characterized in that ...

Embodiment 1 to 6

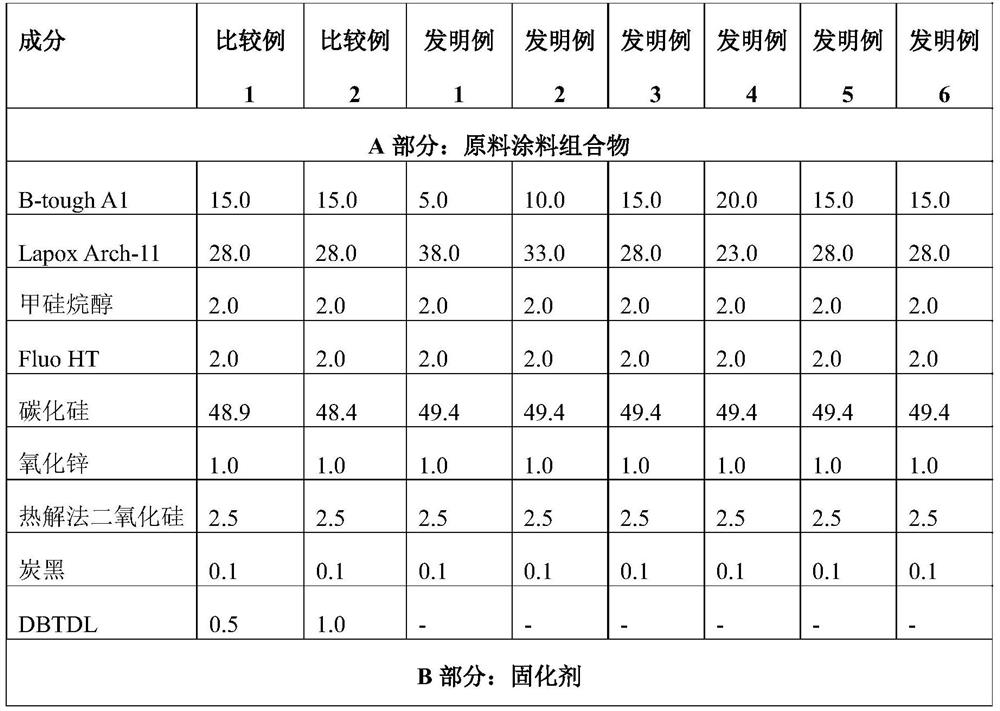

[0192] The formulations given herein below in Table 1 were prepared by using dibutyltin dilaurate (DBTDL) as catalyst (comparative examples 1-2) and without catalyst (inventive examples 1-6). The amount of curing agent (Part B) varies in the examples given. In Table 1, the amount of Part A is given in grams (g) and the weight of Part B is given in grams per 100 grams of Part A.

[0193] Table 1

[0194]

[0195]

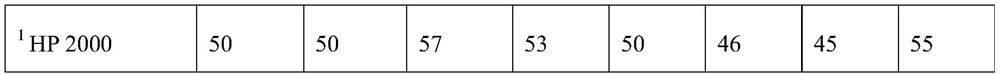

[0196] 1 Weight of HP 2000 for 100 g Part A

[0197] The stability of the stock coating compositions after storage at 50°C for 8 weeks was evaluated and reported herein below in Table 2.

[0198] The two parts (A, B) defined above were mixed and the resulting composition was evaluated for open time / tool time and tack free time. After 24 hours of curing at room temperature, the coating thickness and performance were evaluated by pencil hardness testing, abrasion resistance and salt spray studies.

[0199] Table 2 : Test the performance properties of t...

Embodiment 7-10

[0210] The formulations given herein below in Table 3 were prepared by using dibutyltin dilaurate (DBTDL) as catalyst (comparative examples 3-4) and without catalyst (inventive examples 7-10). The amount of curing agent (Part B) varies in the examples given. In Table 3, the amount of Part A is given in grams (g) and the weight of Part B is given in grams per 100 grams of Part A.

[0211] table 3

[0212]

[0213]

[0214] 5 Indicates the weight of HP 2000 for 100 grams of Part A

[0215] The stability of the stock coating compositions after storage at 50°C for 8 weeks was evaluated and reported herein below in Table 4.

[0216] The two parts (A, B) defined above were mixed and the resulting composition was evaluated for open time / tool time and tack free time. After 24 hours of curing at room temperature, the coating thickness and performance were evaluated by pencil hardness testing, abrasion resistance and salt spray studies. The results are also given in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com