Device for purging cylindrical paper air filter element

An air filter and paper technology, applied in the field of barrel-type paper filter maintenance equipment, can solve problems such as the health impact of workers, susceptibility to lung diseases, and pollution of the surrounding environment, so as to avoid the impact on human health and The effect of polluting the environment, reducing purchase costs and maintenance costs, and preventing dust spills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

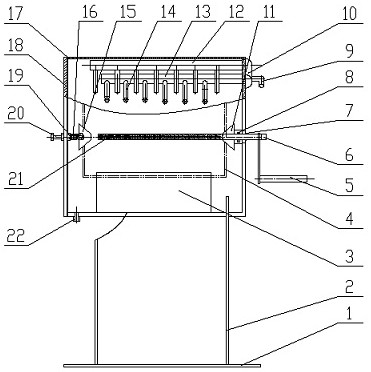

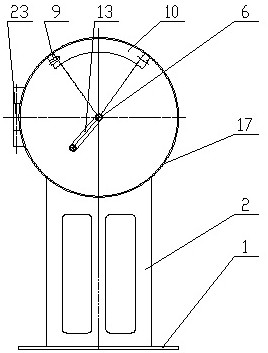

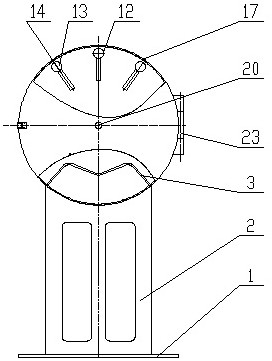

[0025] The present invention consists of a base plate 1, a bracket 2, a purge cylinder 17, an end cover 18, a main air pipe 12, a bronchus 13, an air pipe joint 10, an inner purge pipe 21, a rotary joint 9, a crank 5, a bracket 3 and two The filter element supports the taper sleeve.

[0026] figure 1 , 2 , 3 shows that the bottom plate 1 is a rectangular steel plate, the support 2 is a steel cuboid frame, the lower end of the support 2 is welded to the bottom plate 1, the upper end of the support 2 is a concave semi-circular arc shape, and the arc of the semi-circular arc is the same as the purge The outer circular arcs of the cylinder 17 are matched, and the lower part of the purge cylinder 17 is placed in the semicircular arc at the upper end of the support 2 for welding connection.

[0027] figure 1 , 2 , 3 shows that the purge cylinder 17 is a cylinder, the cylinder of the purge cylinder 17 is horizontally fixed on the upper end of the support 2, one end of the purge c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com