Upper thermal field used for eight inch adulterated arsenic vertical gulling monocrystal manufacture

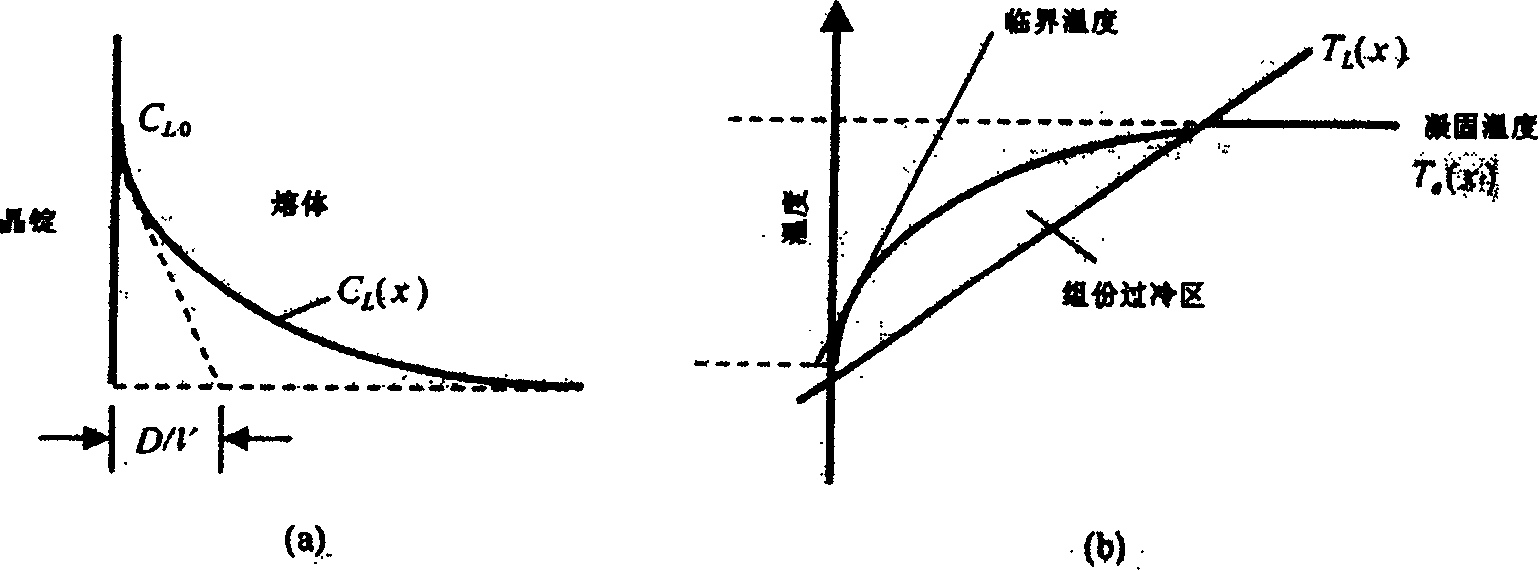

A silicon single crystal, thermal field technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of component supercooling, and achieve the effect of increasing the temperature gradient and strengthening the cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

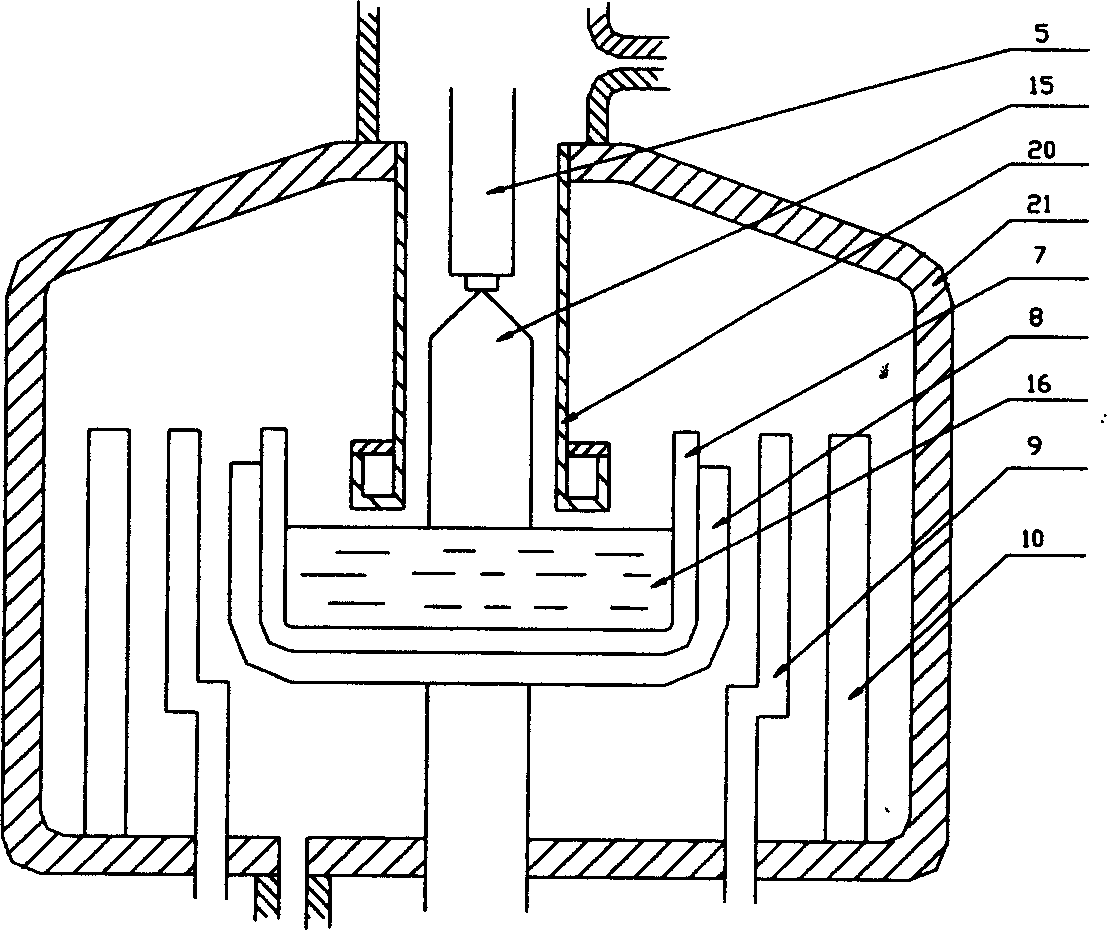

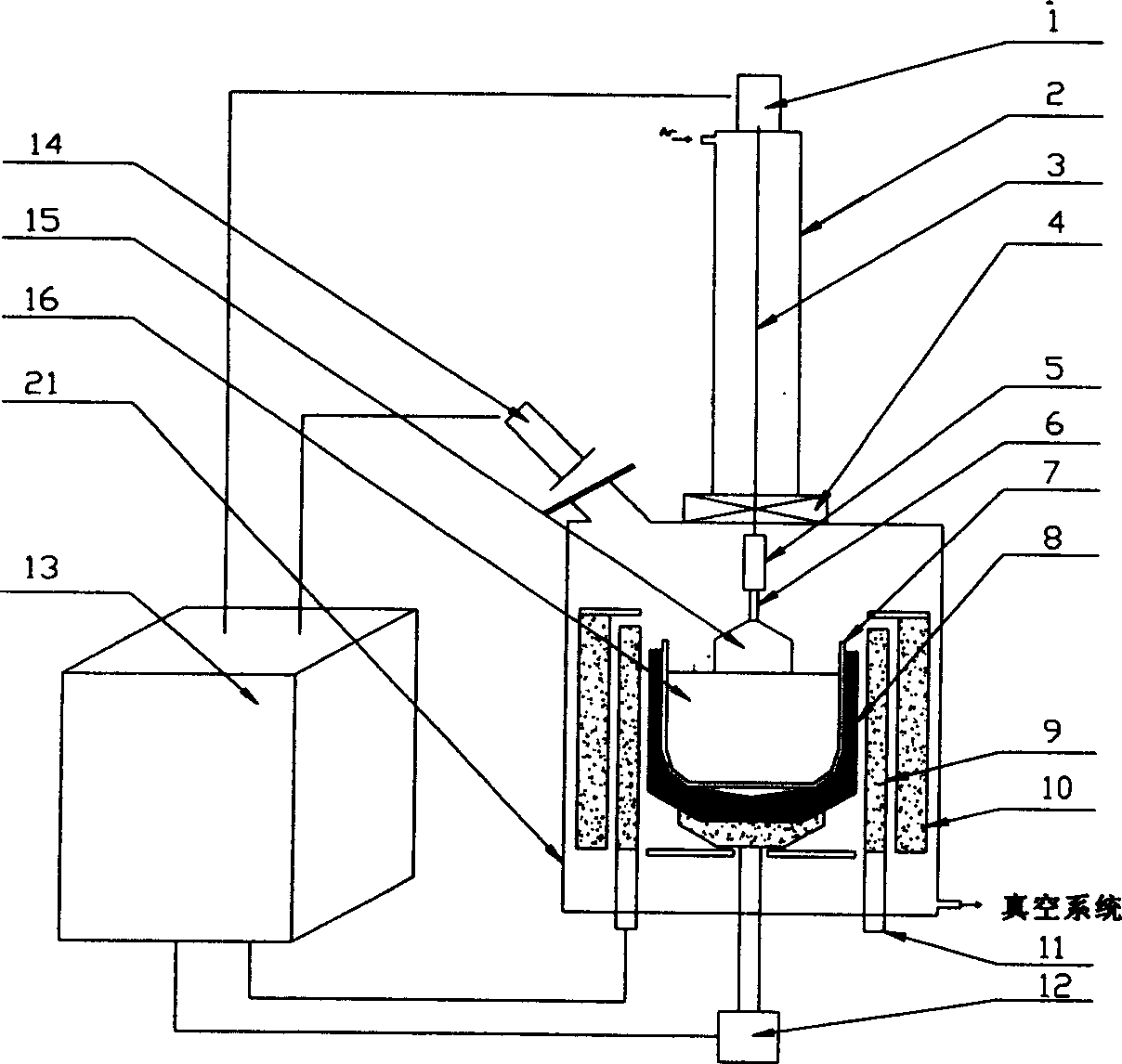

[0027] this invention( Figure 4 The upper part of the melt with hatching) and the ordinary thermal field ( figure 2 ) The main difference is that the novel heat field of the present invention has increased the heat field top that is made up of upper cover plate 22, support cylinder 17, inner air guide cylinder 19, heat preservation cover 23, and these parts are all made by high-purity graphite. The support cylinder 17 and the upper cover plate 18 mainly play the role of support and heat preservation, and the inner air guide cylinder 19 and the heat preservation cover 23 mainly play the role of heat preservation and adjustment of the upper flow field of the melt. The double-layer structure composed of the inner air guide cylinder 19 and the heat preservation cover 23 further enhances the thermal insulation effect of the upper part of the melt, and increases the temperature gradient of the growth interface of the single crystal drawn by a thermal field greater than or equal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com