Machine-made sand conditioning agent preparation device

A technology of sand conditioner and preparation device, applied in mechanical equipment, vibration suppression adjustment, mixer with rotary stirring device, etc., can solve the problems of poor use effect, low strength, poor preparation process, etc. The effect of avoiding damage to the device and improving the usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

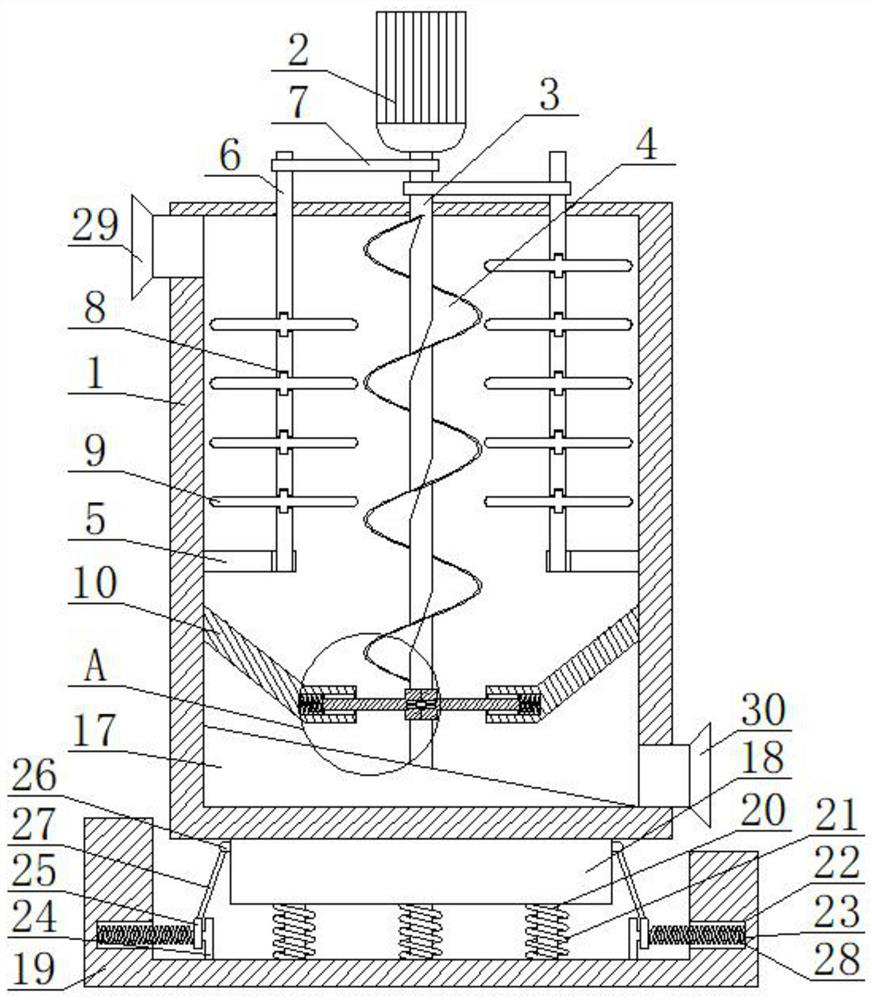

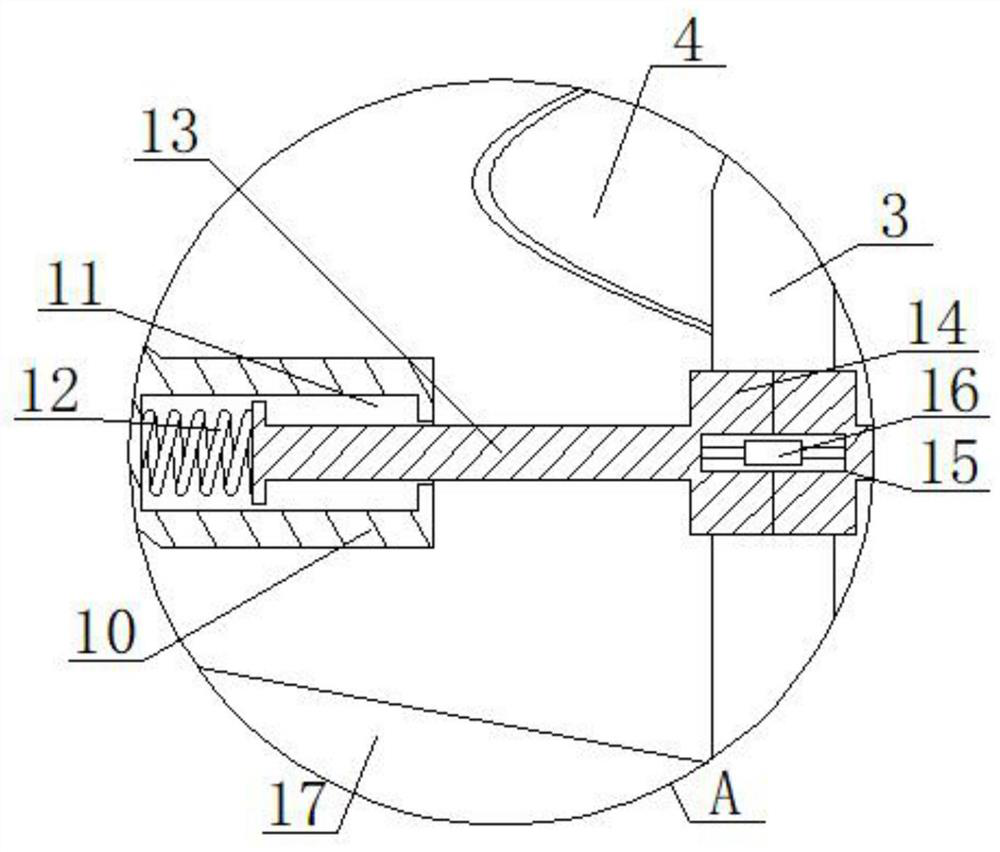

[0025] refer to Figure 1-2 , a machine-made sand conditioner preparation device, including a preparation box 1, the inside of the preparation box 1 is provided with a stirring mechanism and a buffer mechanism, the bottom of the preparation box 1 is provided with a shock absorbing mechanism, and the stirring mechanism is that the top of the preparation box 1 is fixedly connected with a motor 2, The power of the output shaft of the motor 2 is connected with a rotating shaft 3, and the other end of the rotating shaft 3 stretches into the preparation box 1. The tops of the rods 5 are all rotatably connected with a first rotating rod 6, and the other end of the first rotating rod 6 stretches out from the top of the preparation box 1, and the same belt 7 is slidably connected between the first rotating rod 6 and the rotating shaft 3, and the first rotating rod 6. A first chute 8 is evenly opened on the outer wall, and a first stirring rod 9 is slidably connected to the inner wall o...

Embodiment 2

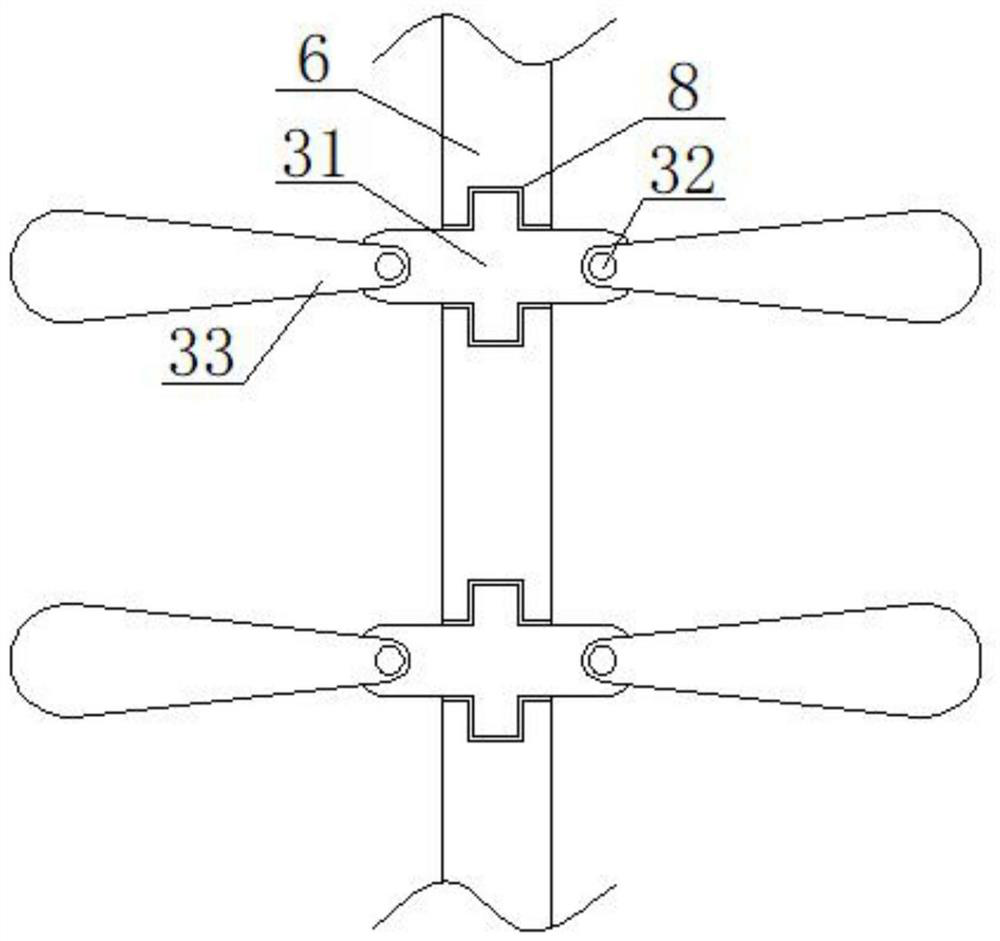

[0029] refer to image 3 , a machine-made sand conditioner preparation device. Compared with Embodiment 1, the inner wall of the first chute 8 is slidably connected with the second hoop 31, and the outer wall of the second hoop 31 is fixedly connected with the rotating bolt 32, and the rotating bolt 32 The outer wall is rotatably connected with a second stirring rod 33 .

[0030] Working principle: when in use, the second stirring rod 33 rotates around the rotating bolt 32 under the action of centrifugal force when the first rotating rod 6 rotates under the drive of the belt 7 through the second hoop 31 and the second stirring rod 33 , the machine-made sand conditioner raw material in the device is more fully stirred, which improves the stirring effect of the device and makes the preparation more complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com