Powder batching system

A batching system and powder technology, applied in the direction of mixer accessories, dissolving, mixing machines, etc., can solve the problems of affecting efficiency, troublesome raw materials, frequent replacement of formula, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

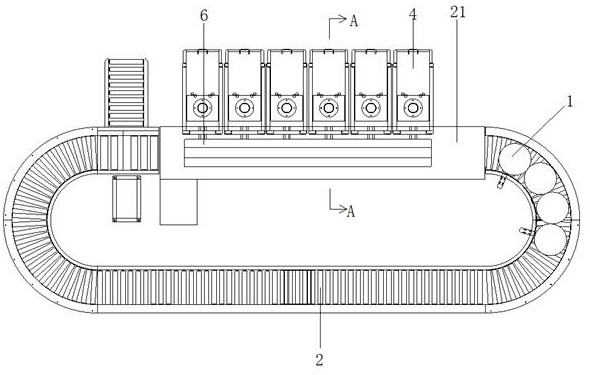

[0030] Such as figure 1 As shown, the present invention includes a weighing bucket 1 for temporarily storing powder and a conveyor belt 2 for transporting the weighing bucket 1. The conveyor belt 2 is a closed ring, and the number of weighing buckets 1 is several.

[0031] On the conveyor belt 2, several weighing devices 3 are equidistantly arranged for measuring the weight of the weighing material barrel 1.

[0032] On the outside of the part where the conveyor belt 2 is provided with a weighing device 3 , corresponding to the weighing device 3 , there are several movable discharge devices 4 for adding powder to the weighing barrel 1 .

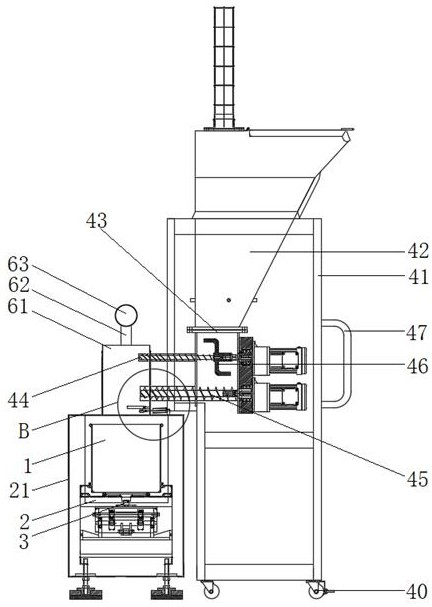

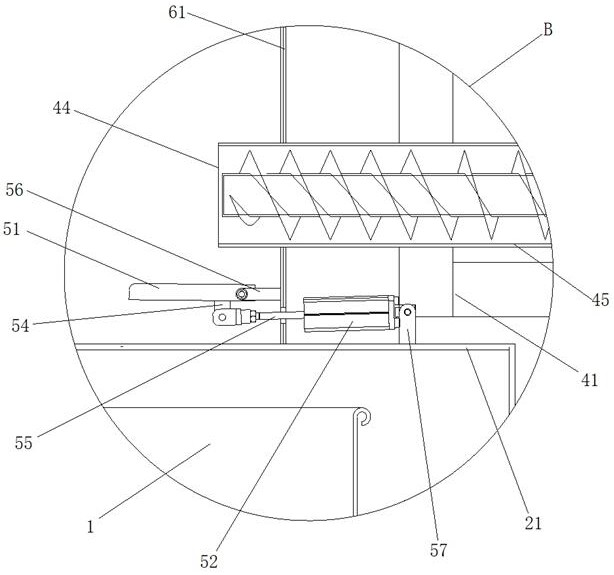

[0033] The discharge device 4 comprises a support 41 with a moving wheel 40 at the bottom, a feeding mechanism in the middle of the support 41, a storage barrel 42 above the feeding mechanism, and the bottom of the storage barrel 42 communicates with the feed end 43 of the feeding mechanism. The lower edge of the delivery end 44 of the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com