Food processing equipment and processing method for mixing multiple food materials

A technology for food processing and ingredients, applied in the fields of food science, cocoa, grain processing, etc., can solve the problems of low quality stability, low manufacturing efficiency, and inability to repeatedly mass-produce complex products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

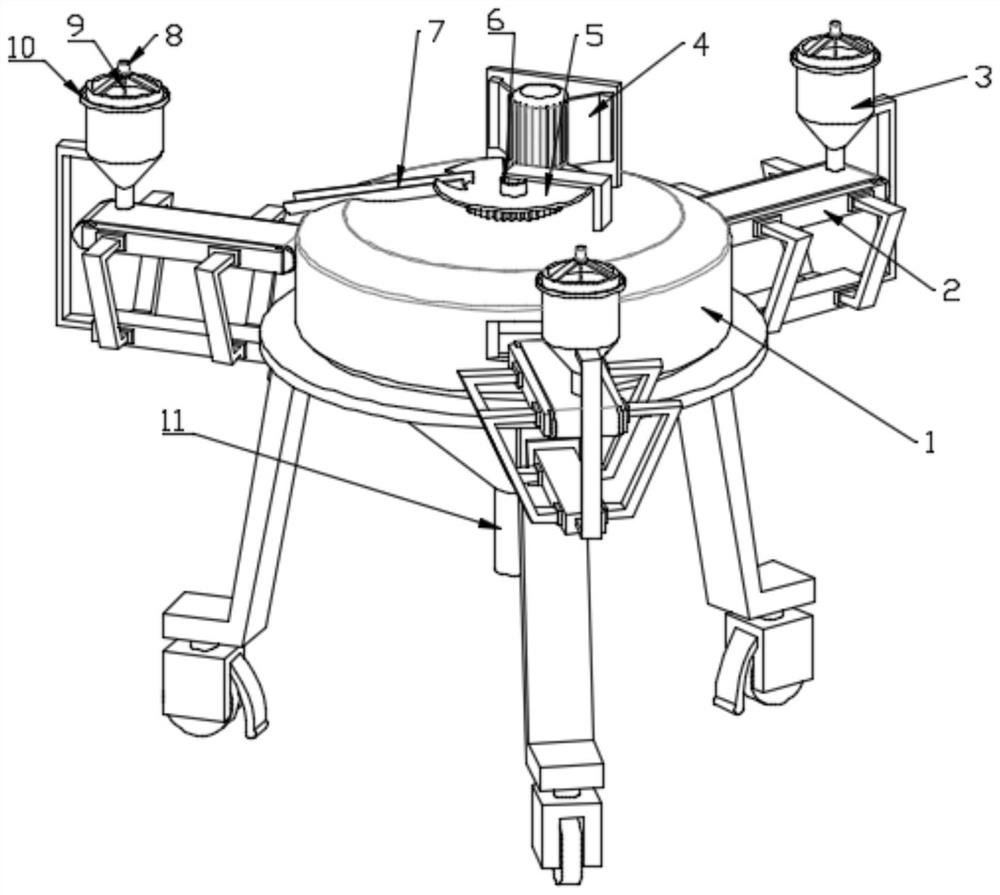

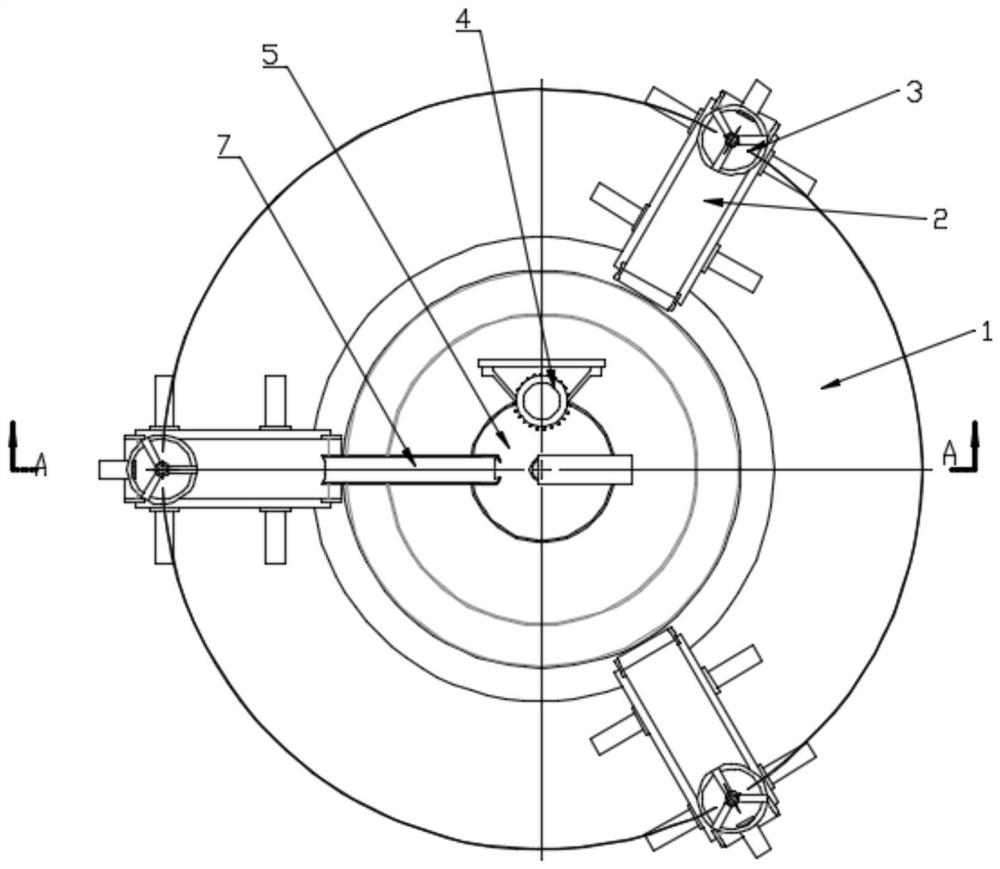

[0043] refer to Figure 1 to Figure 3 , in this embodiment, a food processing equipment for mixing multiple ingredients is proposed, which is used for quantitative, mixing, cutting and grinding of multiple ingredients. The food processing equipment for mixing multiple ingredients includes a processing box 1, a conveyor belt 2 and hopper 3.

[0044] The processing box 1 has a cylindrical structure, and a processing space for food materials is formed inside. The processing box 1 can be made of stainless steel, which ensures the rigidity of the processing box 1 . The processing box 1 may also be a conical barrel structure, and a discharge port 11 is opened at the bottom of the processing box 1 , so as to facilitate the discharge of processed food materials from the discharge port 11 . The bottom of the processing box 1 may be provided with support legs, the bottom of the support legs is fixedly provided with a backing plate, the backing plate is provided with through holes, and ...

Embodiment 2

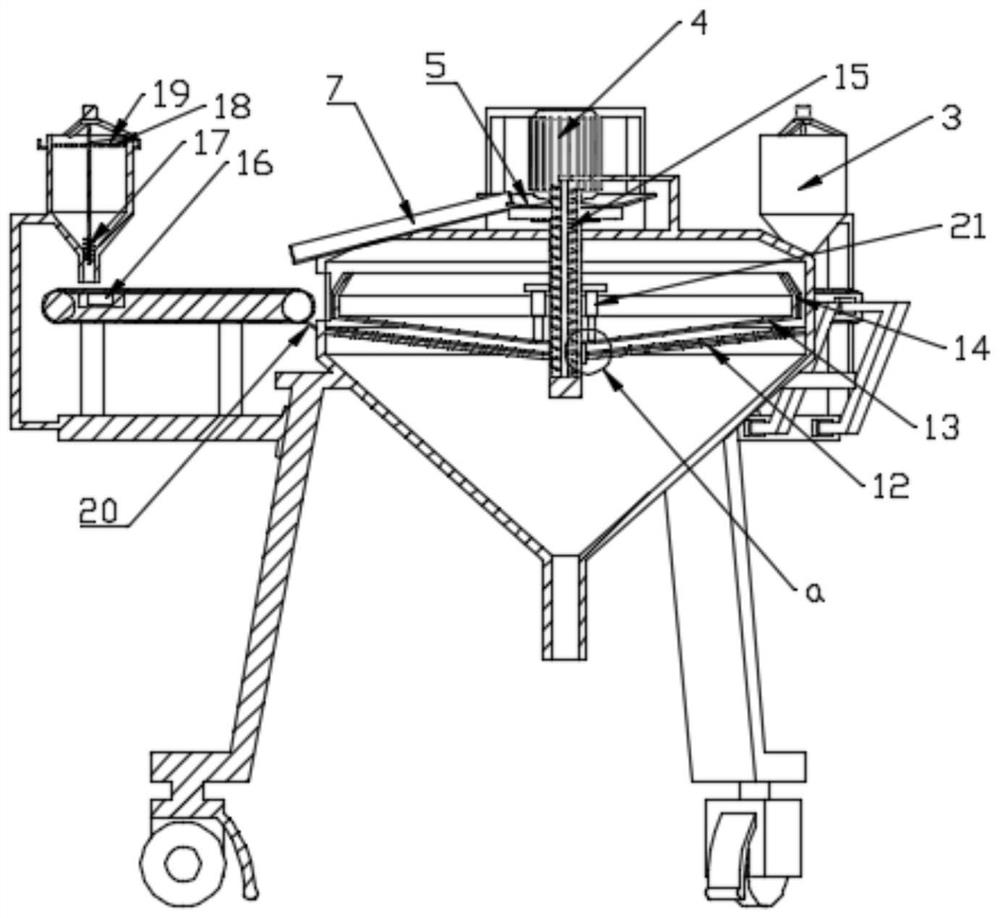

[0054] refer to Figure 4 The outer edge of the upper grinding disc 13 is provided with a cylindrical edge, and the outer wall of the edge is provided with a cutting blade 14 in the circumferential direction. The density of the cutting blade 14 increases gradually from bottom to top. The cutting blade 14 cuts the food entering between the edge and the inner wall of the processing box 1 along with the rotation of the upper grinding disc 13. With the lifting of the upper grinding disc 13, the cutting can be changed. The blade 14 corresponds to the density at the opening, so as to adjust the size of the particles to be cut, and to match the size of the particles to be ground, and has a strong applicability. refer to Figure 5 , the inside of the processing box 1 is radially slidably provided with a gap adjustment plate 22, the gap adjustment plate 22 is located on the side of the opening, and the relative opening direction of the gap adjustment plate 22 is consistent with the ro...

Embodiment 3

[0056] refer to Figure 7 , in the present embodiment, a food processing method for mixing multiple ingredients is proposed, comprising the following steps:

[0057] S1. The food delivery member adjusts the discharge speed of the food.

[0058] S2. The pressure sensor 16 senses the gravity of the falling food.

[0059] S3. Find a preset gravity-mass comparison table to obtain a corresponding mass flow rate of the ingredients.

[0060] S4. Determine whether the ratio of the mass flow rate of each ingredient is the same as a preset mass mixing ratio, and if so, execute S5, and if not, execute S1.

[0061] S5 , the conveyor belt 2 transports the ingredients into the interior of the processing box 1 .

[0062] S6. Search a preset particle size-gap comparison table to obtain the gap between the grinding sieve disc 12 and the upper grinding disc 13 .

[0063] S7. Control the lift drive 21 to adjust the distance between the grinding screen plate 12 and the upper grinding plate 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com