Damping mechanism convenient to mount and use for welding robot

A welding robot and shock absorption mechanism technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of spark splashing, not paying attention to the surrounding environment and personnel protection, to avoid precision and protect the surrounding environment. , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

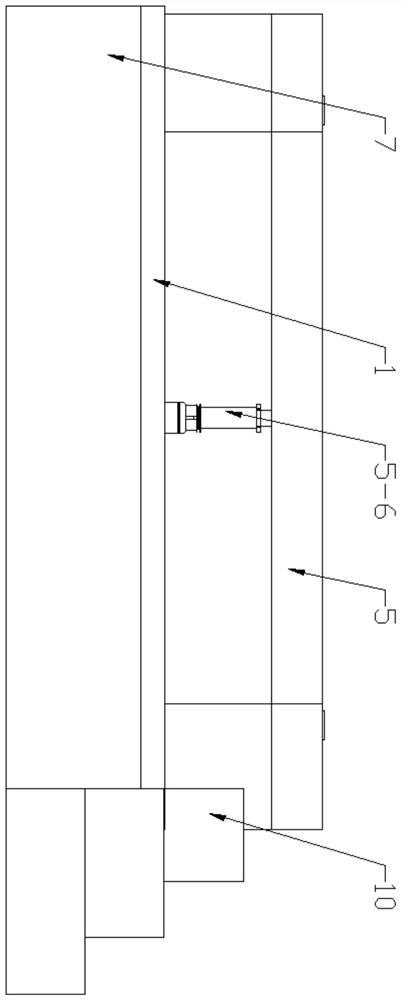

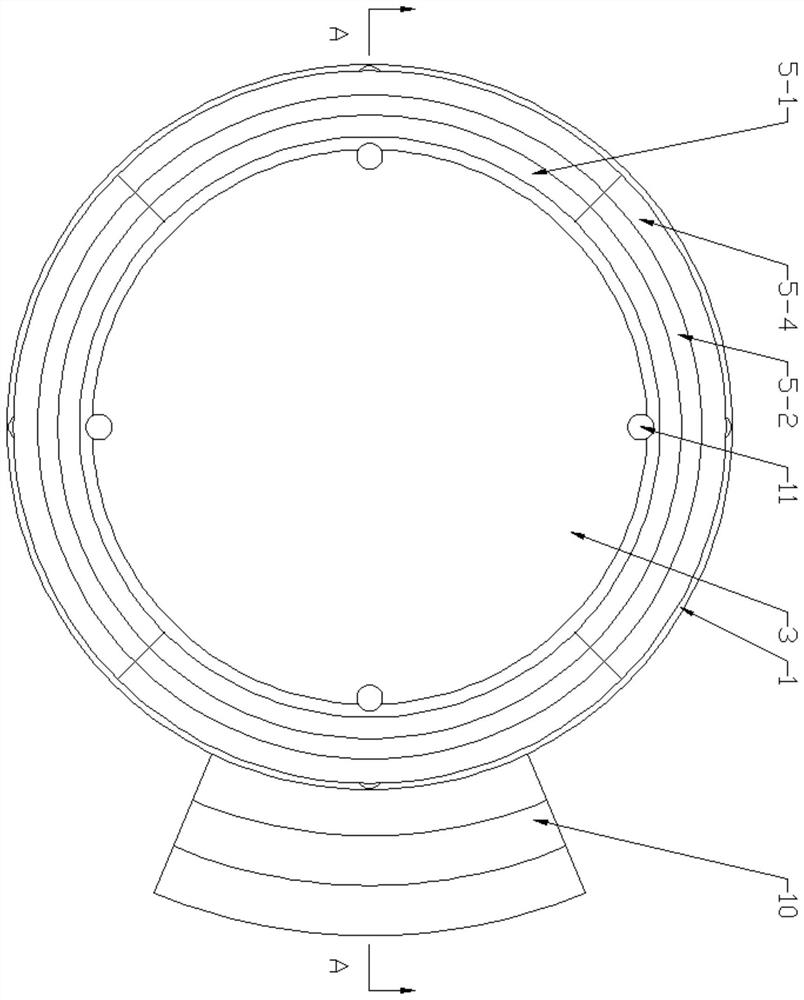

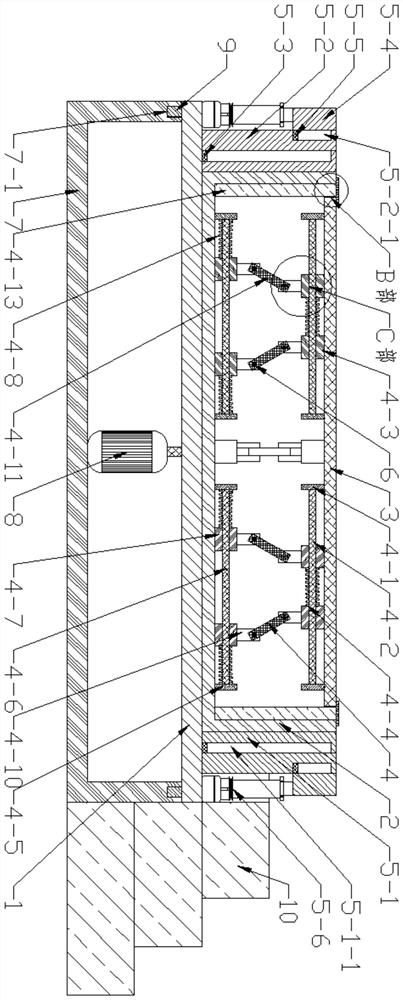

[0052] see as Figure 1 to Figure 7 As shown, the technical solution adopted in this specific embodiment is: it includes a base 1 and an operating table 2; the base 1 is provided with an operating table 2;

[0053] It also contains:

[0054] A movable plate 3, the movable plate 3 is embedded above the inner ring wall of the console 2;

[0055] Shock absorbing mechanism 4, the quantity of described shock absorbing mechanism 4 is four, and is arranged in the operating table 2 respectively in a ring shape, and shock absorbing mechanism 4 comprises:

[0056] The No. 1 fixed plate 4-1, the number of the No. 1 fixed plate 4-1 is two, and they are respectively welded and fixed on the left and right sides of the lower surface of the movable plate 3;

[0057] No. 1 connecting rod 4-2, said No. 1 connecting rod 4-2 is fixed between the left and right No. 1 fixing plates 4-1 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com