Method for removing COD (Chemical Oxygen Demand), ammonia nitrogen and suspended matters in rainwater

A technology for suspended solids and rainwater, applied in chemical instruments and methods, water pollutants, runoff/rainwater treatment, etc., can solve problems that cannot be directly applied to iron and steel enterprises, and achieve good social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

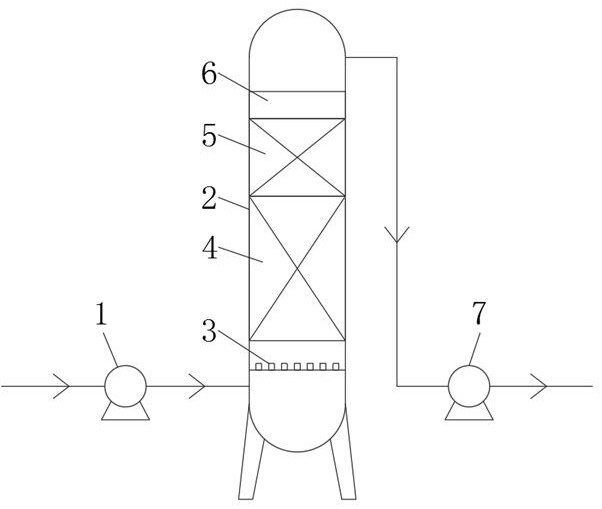

[0026] Such as figure 1 As shown, a method for removing COD, ammonia nitrogen and suspended solids in rainwater includes an inlet pump 1, a multi-layer filter 2 and a drainage pump 7, and the output end of the inlet pump 1 and the input end of the multi-layer filter 2 pass through Pipeline connection, the output end of the multilayer filter 2 is connected with the input end of the drainage pump 7 through a pipeline, and the inside of the multilayer filter 2 is filled with a gravel layer 3, a modified iron slag layer 4, and a modified iron slag layer from bottom to top. Concave-convex soil layer 5 and quartz sand layer 6, gravel layer 3, modified iron slag layer 4, modified concave-convex soil layer 5 and quartz sand layer account for 4%, 50% and 50% of the total volume of multi-layer filter 2 respectively. 42% and 4%, the gravel apparent density of gravel layer 3 is 2510kg / m 3 , the particle size is 100 mesh, the preparation process of the modified iron slag in the modified i...

Embodiment 2

[0036] Such as figure 1 As shown, a method for removing COD, ammonia nitrogen and suspended solids in rainwater includes an inlet pump 1, a multi-layer filter 2 and a drainage pump 7, and the output end of the inlet pump 1 and the input end of the multi-layer filter 2 pass through Pipeline connection, the output end of the multilayer filter 2 is connected with the input end of the drainage pump 7 through a pipeline, and the inside of the multilayer filter 2 is filled with a gravel layer 3, a modified iron slag layer 4, and a modified iron slag layer from bottom to top. Concave-convex soil layer 5 and quartz sand layer 6, gravel layer 3, modified iron slag layer 4, modified concave-convex soil layer 5 and quartz sand layer account for 2%, 48% and 48% of the total volume of multi-layer filter 2 respectively. 48% and 2%, the gravel apparent density of gravel layer 3 is 2440kg / m 3 , the particle size is 100 mesh, the preparation process of the modified iron slag in the modified i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com