Energy-efficient semiconductor plastic package die

A high-efficiency, energy-saving, plastic-encapsulated mold technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of complex replacement of inserts and ejector pins, waste of materials, and long time required to improve product competitiveness. , Reduce production costs, save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

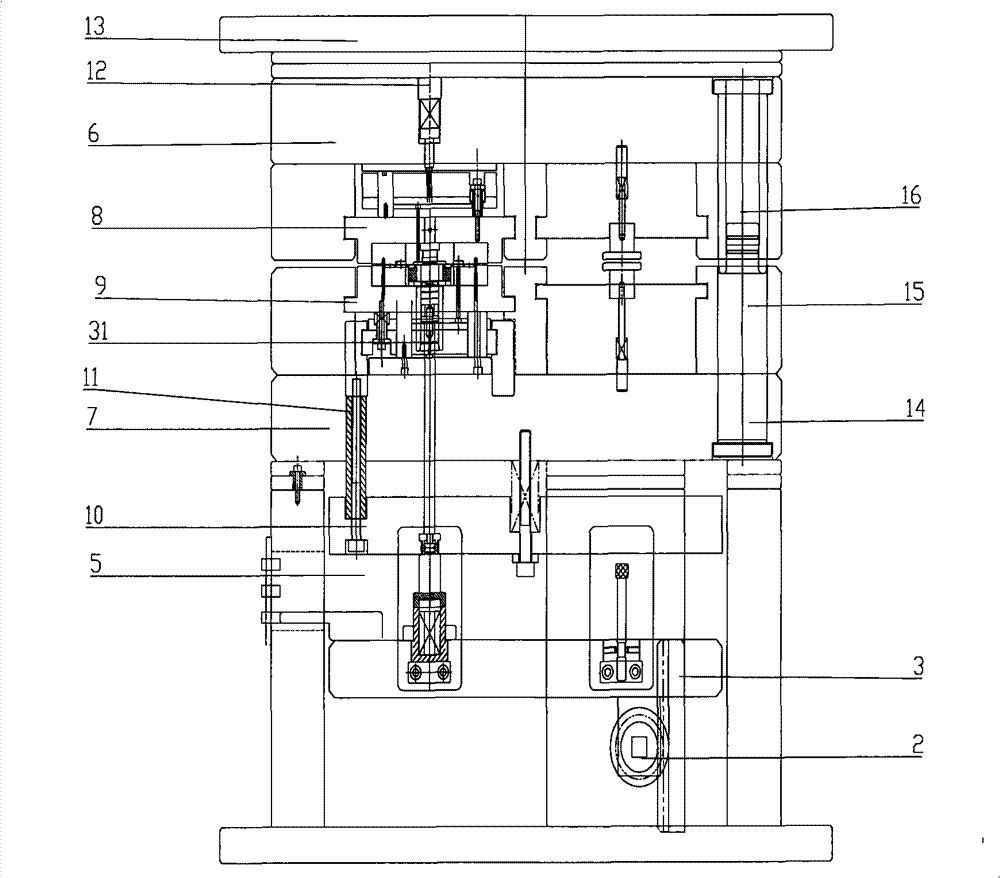

[0020] Such as figure 1 As shown in the multi-cylinder injection molding high-efficiency and energy-saving semiconductor plastic sealing mold, the upper template 6 is fixed with the upper mold box system 8, and the lower template 7 is fixed with the lower mold box 9; the gear rack 2 is connected to the drive transfer plate 3, and reciprocates up and down Move and fix the injection head system on the transfer board 3; the injection head system is connected with the lower center runner plate of the lower mold box 9; The lower mold ejector rod power rod 11 passing through the lower mold plate 7 through the reset rod of the machine tool drives the ejector rod to move upward to eject the molded product and the runner; the upper mold ejector rod reset power system 12 pushes against the upper mold bottom plate 13 and the upper mold box 8, the upper mold ejector rod reset power system 12 drives the upper mold ejector rod to move downward, ejecting the molded product and the runner; af...

Embodiment 2

[0024] Such as figure 1 As shown in the multi-cylinder injection molding high-efficiency and energy-saving semiconductor plastic sealing mold, the upper template 6 is fixed with the upper mold box system 8, and the lower template 7 is fixed with the lower mold box 9; the gear rack 2 is connected to the drive transfer plate 3, and reciprocates up and down Move and fix the injection head system on the transfer board 3; the injection head system is connected with the lower center runner plate of the lower mold box 9; The lower mold ejector rod power rod 11 passing through the lower mold plate 7 through the reset rod of the machine tool drives the ejector rod to move upward to eject the molded product and the runner; the upper mold ejector rod reset power system 12 pushes against the upper mold bottom plate 13 and the upper mold box 8, the upper mold ejector rod reset power system 12 drives the upper mold ejector rod to move downward, ejecting the molded product and the runner; af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com