A kind of material and method for remodeling water-insulating layer of dump site in open-pit mine

A technology for reshaping materials and aquifers, which is applied in earth square drilling, ground mining, underground mining, etc., can solve the problems of open-pit mine water resource loss, large amount, and no research by scholars, and achieve good social and environmental benefits. Simple construction and short setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

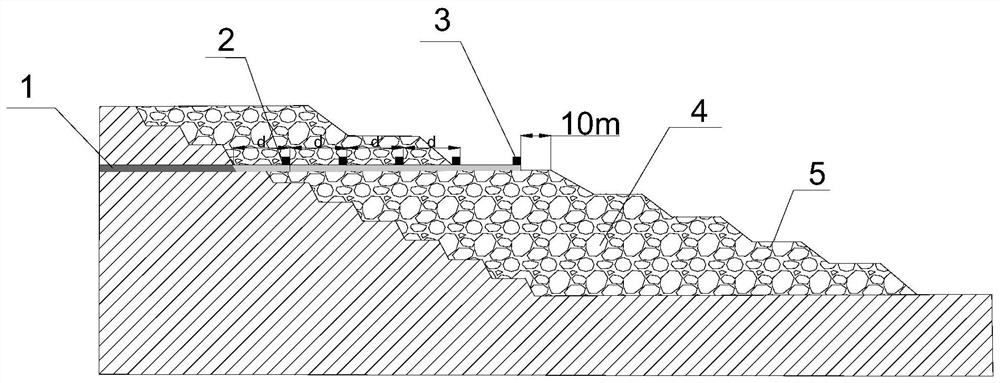

[0037] refer to figure 1 , the construction steps for reshaping the aquifer in the open-pit mine dump are as follows:

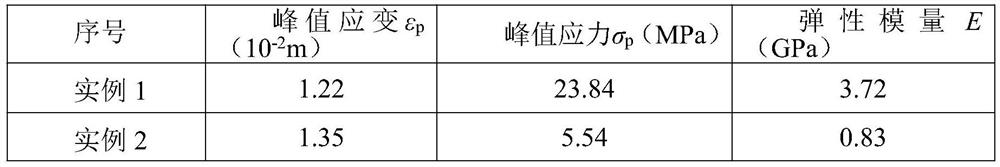

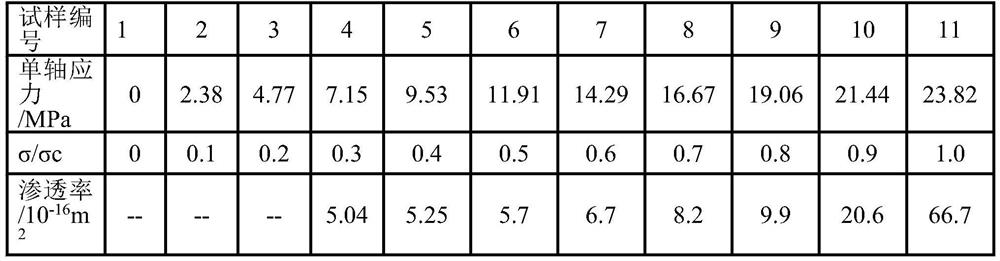

[0038] A. Remodeling material ratio design, determine the level of the remodeling water-resistant layer 2 according to the layer of the original water-resistant layer 1, and determine the physical and mechanical parameters of the remodeled water-resistant layer 2, design the material composition ratio, and indoor Carry out the mix ratio experiment of remolding materials, and test the physical and mechanical parameters such as uniaxial compressive strength and permeability of the remolding samples. The ratio of materials used is:

[0039] remodeling material gel material stimulant water standard sand Material ratio Q 0.2Q 0.5Q Q

[0040] Among them, the proportion of gel material is:

[0041] gel material mudstone powder slag red mud Material mass ratio 30% 50% 20%

[0042] B. When the height of the...

Embodiment 2

[0048] refer to figure 1 , the construction steps for reshaping the aquifer in the open-pit mine dump are as follows:

[0049] A. Remodeling material ratio design, determine the layer level of the remodeling water-resistant layer 2 according to the layer level of the original water-resistant layer 1, and determine the appropriate physical and mechanical parameters of the remodeled water-resistant layer 2, and design the material composition ratio. Experiments on the ratio of remolded materials were carried out indoors to test physical and mechanical parameters such as uniaxial compressive strength and permeability of remolded samples. The ratio of materials used was:

[0050] remodeling material gel material stimulant water standard sand Material ratio Q 0.1Q 0.5Q Q

[0051] Among them, the proportion of gel material is:

[0052] gel material mudstone powder slag red mud Material proportion 70% 15% 15%

[0053] Steps ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com